Cheppali Cp 120

| Cheppali Cp 120 | |

|---|---|

| |

| Role | Fighter |

| National origin | Tennai |

| Manufacturer | Cheppali |

| Designer | Gitikasri Prithiyanga |

| First flight | March 1936 |

| Introduction | February 1937 |

| Retired | 1948 |

| Status | Retired |

| Primary user | Royal Tennaiite Air Force |

| Produced | 1936-1947 |

| Number built | 15,468 |

The Cheppali Cp 120 was a Tennaiite Siduri War fighter aircraft design from Cheppali. It served alongside the Cheppali Cp 117 and Nikita N.167.

Development

Following the selection by the RTA of the Cp 117 as the next single-seat fighter, Gitikasri Prithiyanga became interested in a new fighter that would leap beyond the performance of the Cp 117 as much as the Cp 117 had over the biplanes it replaced. Other Tennaiite designers had similar ambitions, including Kanira Velamuri of Devati. Both companies brought there ideas to the Air Ministry in 1934 and were immediately given the go-ahead and the funding for development. Both fighters were intended as high-performance fighters with a combat range substantially greater than other contemporary fighters. Cheppali pursued the singe-engine Cp 120 while Devati pursued the twin-engine, heavy-fighter style Devati 191.

Gitikasri Prithiyanga, on half of the famous Prithiyanga sisters, looked at the existing Cp 117, which had already entered production, and decided it had reached the end of it basic evolution. She started with a completely new design, Project 1041. Learning from past difficulties on the Cp 117 project, the design was to be as easy to build as possible yet 700 km/h (380 kn; 430 mph) was a design goal. To ease production, the new design had considerably fewer parts than the Cp 117 and those that remained contained fewer compound curves. In comparison, the 117 had 2,885 parts and 26,864 rivets, while the P.1041 was made of 969 unique parts with 11,543 rivets. The new straight-edged wing was a source of much of the savings; after building the first wings, it was reported that the reduction in complexity and rivet count (along with an explosive rivet system) saved an astonishing 1,150 man hours per wing.

Gitikasri Prithiyanga was killed in a car accident on 25 May 1935, and the design work was taken over by her twin sister Lathusa, who finished the final draft design later that year. Lavany Rukshie, a specialist in aircraft structures, also played a prominent role in the design. At the end of October, the design was submitted to the RTA, complete with details on prototypes, delivery dates and prices for three aircraft delivered to the Devangala test center.

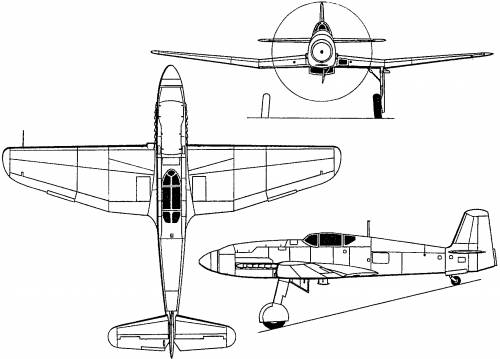

Design

In order to get the promised performance out of the aircraft, the design included a number of drag-reducing features. On the simple end was a well-faired cockpit, the absence of struts and other drag-inducing supports on the tail. The landing gear (including the tailwheel) was retractable and completely enclosed in flight.

The engine chosen for the Cp 120 was the Kamala 1710, the same engine that powered the Nikita NB-160 Durva heavy bomber. The engine was chosen for its excellent high altitude performance provided by a two-stage supercharger. In order to reduce weight and frontal area, the engine was mounted directly to the forward fuselage, which was strengthened and literally tailored to the Kamala 1710, as opposed to conventional mounting on engine bearers. The cowling was very tight-fitting, and as a result the aircraft has something of a slab-sided appearance.

In order to provide as much power as possible from the Kamala 1710, exhaust ejectors were used to provide a small amount of additional thrust. The supercharger inlet was moved from the normal position on the side of the cowling to a location in the leading edge of the left wing, which was also a feature of the earlier and larger Cp 119 experimental high-speed reconnaissance aircraft. Although cleaner-looking, the long, curved induction pipe most probably negated any benefit.

Engine collant and oil cooling systems

For the rest of the designed performance increase with the Kamala 1710 powerplant, Gitikasri turned to the somewhat risky and still experimental method of cooling the engine via evaporative cooling. Such systems had been in vogue in several countries at the time. Cheppali and the Prithiyanga sisters were avid proponents of the technology, and had previously used it on the Cp 119, with promising results. Evaporative or "steam" cooling promised a completely drag-free cooling system. The Kamala 1710 was a pressure-cooled engine in that the water/glycol coolant was kept in liquid form by pressure, even though its temperature was allowed to exceed the normal boiling point. Cheppali's system took advantage of that fact and the cooling energy loss associated with the phase change of the coolant as it boils. Following is a description of what is known about the final version of Cheppali's cooling system. It is based entirely on careful study of surviving photographs of the Cp 120, since no detailed plans survive.

Coolant exits the Kamala 1710 at two points located at the front of the engine and at the base of each cylinder block casting immediately adjacent to the crank case. In the Cheppali system, an "S"-shaped steel pipe took the coolant from each side of the engine to one of two steam separators mounted alongside the engine's reduction gear and immediately behind the propeller spinner. The separators accepted the water at about 110 °C (230 °F) and 1.4 bar (20 psi) of pressure. The vertically mounted, tube-shaped separators contained a centrifugal impeller at the top connected to an impeller-type scavenge pump at the bottom. The coolant was expanded through the upper impeller where it lost pressure, boiled and cooled. The by-product was mostly very hot coolant and some steam. The liquid coolant was slung by the centrifugal impeller to the sides of the separator where it fell by gravity to the bottom of the unit. There, it was pumped to header tanks located in the leading edges of both wings by the scavenge pump. The presence of the scavenge pump was necessary to ensure the entire separator did not simply fill up with high-pressure coolant coming from the engine.

Existing photographs of the engine bay of the final pre-production version of this system clearly show the liquid coolant from both separators was piped along the bottom left side of the engine compartment and into the right wing. The header tanks were located in the outer wing panels ahead of the main spar and immediately outboard of the main landing gear bays. The tanks extended over the same portion of the outer panel's span as the outer flaps. Coolant from the right wing header tank was pumped by a separate, electrical pump to the left wing header tank. Along the way from the right to left wing, the coolant passed through a conventional radiator mounted on the bottom of the fuselage. That radiator was retractable and intended for use only during ground-running or low-speed flight. Nevertheless, coolant passed through it whenever the engine was running and regardless of whether it was extended or retracted. In the retracted position, the radiator offered little cooling, but some heat was exchanged into the aft fuselage. Finally, a return tube connected the left wing's header tank to that on the right. This allowed the coolant to equalize between the two header tanks and circulate through the retractable radiator. The engine drew coolant directly from both header tanks through two separate pipes that ran through the main landing gear bays, up the firewall at the back of the engine compartment, and into the usual coolant intakes located at the top rear of the engine.

The steam collected in the separators was vented separately from the liquid coolant. The steam did not require mechanical pumping to do this, and the buildup of pressure inside the separator was sufficient. The steam was piped down the lower right side of the engine bay and led into the open spaces between the upper and lower wing skins of the outer wing panels. There, it further expanded and condensed by cooling through the skins. The entire outer wing, both ahead of and behind the main spar, was used for this purpose covering that portion of the span containing the ailerons (the fuel was also carried entirely in the wings and occupied the areas behind the main spar in the center section and immediately ahead of the outboard flaps). The condensate was scavenged by electrically-driven centrifugal pumps and fed to the header tanks. Sources indicate as many as 22 separate pumps were used for this, each with their own attendant pilot light on the instrument panel, but it is not clear whether that number includes all of the pumps in the entire water- and oil-cooling systems or merely the number of pumps in the outer wing panels. The former is generally accepted.

Some sources state the outer wing panels used double skins top and bottom with the steam being ducted into a thin space between the outer and inner skins for cooling. A double-skinned panel was used in the oil cooling system, but surviving photographs of the wings indicate that they were conventionally single-skinned, and that the coolant was simply piped into the open spaces of the structure. Double skinning over such an extensive area would have made the aircraft unacceptably heavy. Furthermore, there was no access to the inner structure to repair damage such as a bullet hole from the inside, as would be needed if the system used a double skin.

Unlike the cooling fluid, oil cannot be allowed to boil. This presented a particular problem with Kamala 1710-series engines, because oil is sprayed against the bottom of the pistons, resulting in a considerable amount of heat being transferred to the oil as opposed to the coolant. The Cp 120's oil cooling system was conceptually similar to the water cooling system in that vapor was generated using the heat of the oil and condensed back to liquid by surface cooling through the skins of the airframe. A heat exchanger was used to cool the oil by boiling ethyl alcohol. The oil itself was simply piped to and from this exchanger, which was apparently located in the aft fuselage. The alcohol vapor was piped into the fixed portions of the horizontal and vertical stabilizers and into a double-skinned portion of the upper-aft fuselage behind the cockpit. This fuselage "turtle deck" panel was the only double-skinned portion of the aircraft's cooling system. The use of a double-skinned panel was possible here because the inside of panel was accessible in the event of repair. Condensed alcohol was collected by a series of bellows pumps and returned to a single header tank that fed the heat exchanger. Some sources speculate that a small air intake located at the bottom front of the engine cowl was used for an auxiliary oil cooler. No such cooler was fitted, nor was there room for one at that point. This small inlet served simply to admit cool air into what was a very hot portion of the engine bay. Immediately above this vent were the two steam separators, and immediately behind it were the hot coolant pipes coming from the separators.

World speed record

Prototypes

Operational history

Siduri War

Foreign use

Variants

- D-1 - Initial production variant with 1175 hp Kamala 1710 engine 2 x 7.93 mm machine guns and 1 x 20 mm cannon.

Operators

Specifications (Cp 1120 D-1)

General characteristics

- Crew: 1

- Length: 8.2 m (26 ft 11 in)

- Wingspan: 9.4 m (30 ft 10 in)

- Height: 3.60 m (11 ft 10 in)

- Wing area: 14.6 m2 (157 sq ft)

- Empty weight: 1,810 kg (3,990 lb)

- Max takeoff weight: 2,500 kg (5,512 lb)

- Fuel capacity: 300 kg (660 lb)

- Powerplant: 1 × Kamala 1710 V-12 inverted liquid-cooled piston engines, 876 kW (1,175 hp)

- Propellers: 3-bladed constant-speed propellers, 2.8 m (9 ft 2 in) diameter

Performance

- Maximum speed: 670 km/h (416 mph; 362 kn) at 6,000 m (19,685 ft)

- Cruise speed: 552 km/h (343 mph; 298 kn)

- Range: 2,020 km (1,255 mi; 1,091 nmi)

- Combat range: 1,010 km (628 mi; 545 nmi)

- Service ceiling: 11,000 m (36,000 ft)

- Time to altitude: 6,000 m (19,685 ft) in 7.8 minutes

Armament

- Guns:

- 2 × 7.93 mm (0.312 in) Basu HV 80 machine guns in wings

- 1 x 20 mm (0.787 in) Basu FG 20-20 cannon firing through propeller hub

Avionics

Kol 89Z radio