Kolibri (Aircraft)

This article is incomplete because it is pending further input from participants, or it is a work-in-progress by one author. Please comment on this article's talk page to share your input, comments and questions. Note: To contribute to this article, you may need to seek help from the author(s) of this page. |

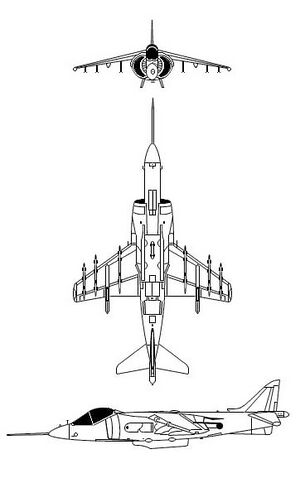

| Haugen Kolibri | |

|---|---|

| A Lumenic Kolibri demonstrating vertical take off. | |

| Role | V/STOL strike aircraft |

| National origin | |

| Manufacturer | Haugen Luftfartsselskap1968-1977 1977-19XX Trinovantanske Luftfartssystemer |

| Designer | Haugen Luftfartsselskap |

| First flight | January 5th, 1968 |

| Produced | 19XX-?? |

The Haugen Kolibri is a jet-powered strike aircraft developed by Haugen Luftfarsselskap and later produced by Trinovantanske Luftfartssystemer. It featured the novel capability to take off and land vertically. Originally developed to act as a low cost, low footprint forward-deployed close-air-support aircraft for the Trinovantan Military in the 1960s, using improvised air bases to mitigate the potential danger of deep-interdiction strikes against Trinovantan air bases.

Though the initial aircraft did not gain interest from the Trinovantan Military, it was put out for export in an attempt to recoup development costs. The Lumenic Legion were the primary operators of the Kolibri, purchasing several examples during the Omandan Continental War. Its performance in the hands of Lumenic aviators caused interest in the Kolibri to spike, resulting in the once-scorned aircraft becoming a surprise success on the export market. This success spawned two notable derivatives: the carrier-capable Sjøkolibri and the enhanced Kolibri II, both of which would be adopted by the Trinovantan Military.

Though strategically successful in foreign service, the aircraft was not free of criticism. In an age of supersonic aircraft, the subsonic Kolibri was lacking in most areas of direct comparison. The complex VTOL mechanisms were considered difficult to maintain and were often blamed for the aircraft’s higher than average accident rate.

Development

One of the key aspects that drove the Kolibri’s design was the perceived vulnerability of airbases to advancing weapons technology. Aircraft were becoming ever faster and thus difficult to intercept before reaching their targets. New cruise and ballistic missiles could strike static targets from deep behind enemy lines without endangering their operators. These threats could effectively ground the Trinovantan Military’s air wings by destroying the infrastructure required to operate aircraft.

However, if that infrastructure requirement could be bypassed then this vulnerability would disappear. This idea would be what spurred Haugen to develop the concept of vertical takeoff and landing capability for fixed wing aircraft. The conventional methods of achieving this at the time were the use of an independent rotor or lift jets. However, the limitations of either of these systems would negatively impact a proper fixed wing design. Thus, Haugen would develop a new method in the form of a vectored thrust turbofan via a partnership with the Calland og Wolden engine manufacturer.

A proof of concept prototype demonstrated the viability of this system by achieving a vertical take-off and transition into horizontal flight in May of 1961. With this system now proven to work, development began on a combat-capable airframe while the proof of concept prototype became a testbed for various systems intended for the production aircraft. Development would continue towards a larger airframe which could carry a modest air-to-ground payload. The tentative design for a production aircraft would have a longer fuselage with a wider wingspan, resulting in an empty weight increase from 4400 kg to 6100 kg. A new engine would have to be designed, based on the proof of concept engine but with increased output to facilitate the production aircraft’s larger dimensions.

By the start of 1968, the first pre-production airframe took flight. However, over the time of its development Trinovantan interest in the aircraft waned. The capabilities of conventional fixed wing aircraft had grown substantially over the course of the Kolibri’s development. While the Kolibri was comparable to the aircraft of the late 50s, by 1968 the subsonic Kolibri was considered to be underpowered and under-equipped to compete with its peers.

With the program’s domestic prospects looking grim, Haugen turned to the international market to try and salvage some of the cost of developing the complex aircraft. [ Talk with Doober about when Lumieland would buy the aircraft and what features they would desire/request before/after buying ]

Design

The Kolibri was, from the onset, intended to be a dedicated strike aircraft and its design reflects that fact. The use of a non-afterburning engine inherently restricted the Kolibri’s achievable speed and the lack of an on-board RADAR limited its ability to intercept other aircraft. However, the aircraft did possess good low-speed maneuverability which could allow it to gain the advantage during an air-to-air engagement, especially if equipped with short range self-guiding air to air missiles. The aircraft was limited in its payload capacity, only having four under wing pylons and a single fuselage pylon each with a capacity of 500 kg. Two dedicated gun pod pylons are also present on the fuselage for use with the LkMk-10 revolver cannon. These gun pods carry 130 rounds of ammunition each, for a total of 260 with a cumulative rate of fire of 2400 rounds per minute. The center fuselage pylon is usually reserved for drop tanks but can carry ordinance as well, though this is rare due to weight restrictions.

The crux of the Kolibri’s design lies in its single FJ-102V turbofan engine. Located in the center of the fuselage and fed by two intakes beside the cockpit, this engine directs its exhaust not through a single fixed nozzle as per most conventional aircraft but through four vectoring nozzles located along the sides of the fuselage. These nozzles are capable of rotating from horizontal to vertical in order to redirect thrust and achieve vertical flight. The engine is equipped with a water injection system to increase the engine’s output during vertical takeoffs and landings, which can be necessary to control the aircraft when it is carrying a combat load. When hovering, the conventional control surfaces are not functional due to lack of airflow. In these situations, attitude control comes in the form of several small reaction thrusters on the nose, tail and wingtips of the aircraft.

In addition to the normal flight controls that are common to most aircraft, the Kolibri possess a vectoring lever in the cockpit, which controls the direction of the four vectoring nozzles. When in the forward position the nozzles are horizontal to the airframe and the Kolibri controls are largely similar to any other fixed wing aircraft. However, when the lever is pulled down to a vertical position the engine nozzles are rotated downward and the engine’s bypass air is redirected to reaction nozzles to facilitate vertical flight. This lever is not a two-position system, and is capable of being partially rotated between 0 and 98 degrees relative to the fuselage. The 0 degree position is used in conventional flight, whereas a position between 85-95 degrees is used to enter and control the aircraft in vertical flight. A diagonal position is often used to reduce takeoff length, as this is more efficient and less stressful on the airframe than attempting to takeoff vertically.

Because the aircraft’s flight characteristics can change radically based on its engine’s thrust vectoring position, the Kolibri is considered to be a challenging aircraft to learn how to fly. Though its systems are well designed and intuitive to use, the fundamental differences between conventional forward flight and reaction-thrust controlled vertical flight are frequently confusing and hard to master. For this reason, it was recommended that prospective Kolibri pilots have some experience in piloting helicopters as this experience should translate to the Kolibri’s challenging vertical flight characteristics. For vertical flight, it is recommended to point the nose of the aircraft into the direction of the wind to mitigate drift when hovering. The recommended short-takeoff procedure is to accelerate with the nozzles in a horizontal position until reaching a set speed, then rotating the nozzles into a diagonal position. The angle of the nozzles will be determined by the desired take-off speed, with a lower speed corresponding to a higher nozzle angle.

In order to facilitate its strike role, the Kolibri was equipped with the Hawken Allmennaksjeselskap LkDbNa-53 inertial navigation suite. This allowed the aircraft to self-navigate through preset courses, which was considered important as it would often be operating without the benefit of an established air base to track them from their point of origin. Though initially only equipped with a basic countermeasure dispenser, the Kolibri would be incrementally upgraded with a radar warning system and missile approach warning system as well as pylon-mounted ECM equipment. These systems aid the pilot by not only alerting them to potential missile threats but indicating which equipped countermeasure systems would be most effective against the threat.

Operational History

[ Lumieland service ]

Variants

[ Potential Lumieland Modifications ]

Operators

[ Lumieland Branches ]

Specifications

General characteristics

- Crew: 1

- Length: 14.3 m (46 ft 11 in)

- Wingspan: 7.75 m (25 ft 5 in)

- Height: 3.63 m (11 ft 11 in)

- Wing area: 18.7 m2 (201 sq ft)

- Empty weight: 6,140 kg (13,536 lb)

- Max takeoff weight: 11,430 kg (25,199 lb)

- Internal fuel capacity: 2,295 kg (5,060 lb)

- Powerplant: 1 × Calland og Wolden FJ-102V vectored-thrust turbofan , 96 kN (22,000 lbf) thrust

Performance

- Maximum speed: 635 km/h (395 mph; 343 kn) at sea level

- Never exceed speed: 1,600 km/h (994 mph; 864 kn)

- Combat range: 670 km (416 mi; 362 nmi) hi-lo-hi with 2000 kg payload

- 370 km (230 mi) lo-lo with 2000 kg payload

- Ferry range: 3,430 km (2,131 mi; 1,852 nmi)

- Service ceiling: 15,600 m (51,200 ft)

- g limits: +8.0 -4.0

Armament

- Guns: 2x 30mm LkMk-10 cannon pods (260 rounds total)

- Hardpoints: 5 with a combined capacity of 2200 kg

- 4x Under-Wing hardpoints with a capacity of up to 500 kg

- 1x Center-line hardpoint rated for 500 kg

Avionics

- RWR

- MAWS

- IFF

- UHF Communications

- TACAN Navigation

- Inertial Navigation System

- Laser Targeting Pods (optional)