Tarskvagn-141: Difference between revisions

No edit summary |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 95: | Line 95: | ||

{{Modern tanks in Pardes}} | {{Modern tanks in Pardes}} | ||

The '''Tarskvagn-141''' (TskVg-141) is a domestically produced {{wp|Main Battle Tank}} from [[Dniegua]]. Intended to supplement the [[Tarskvagn-124]] in armored units, and later replace it all together, the Tskvg-141 represents a major leap in armored capability and design in the 20th century. Commonly called the '''T-vagn''' | The '''Tarskvagn-141''' (TskVg-141) is a domestically produced {{wp|Main Battle Tank}} from [[Dniegua]]. Intended to supplement the [[Tarskvagn-124]] in armored units, and later replace it all together, the Tskvg-141 represents a major leap in armored capability and design in the 20th century. Commonly called the '''T-vagn''', the TskVg-141 is armed with a 140mm L/45 smoothbore gun with 32 rounds, as well as a Coaxial 40x364mm cannon. The commanders station is provided with a shielded sled mount, allowing all AEN 4589 standard light weapons to be mounted. | ||

The TskVg-141 development started in the late 1980s as a plan to defeat modern evolving composite armors from longer ranges. Economic situations and issues slowed development as funds were diverted from armored projects to stop-gap solutions such as gun-launched anti-tank guided missiles ({{wp|Anti-tank missile|GLATGMs}}), which ensured little (if any) development took place through most of the early 1990s. The project was revitalized in the mid 1990s as it became apparent that current production MBTs would be unable to reliably fight and defend from next-generation main battle tanks. Prototypes entered trials in 2002, and the first vehicles were adopted in 2004. Today, Dniegua is the largest operator of the TskVg-141 with 1,600 in service, with plans to acquire over 1,000 more within the next decade. | The TskVg-141 development started in the late 1980s as a plan to defeat modern evolving composite armors from longer ranges. Economic situations and issues slowed development as funds were diverted from armored projects to stop-gap solutions such as gun-launched anti-tank guided missiles ({{wp|Anti-tank missile|GLATGMs}}), which ensured little (if any) development took place through most of the early 1990s. The project was revitalized in the mid 1990s as it became apparent that current production MBTs would be unable to reliably fight and defend from next-generation main battle tanks. Prototypes entered trials in 2002, and the first vehicles were adopted in 2004. Today, Dniegua is the largest operator of the TskVg-141 with 1,600 in service, with plans to acquire over 1,000 more within the next decade. | ||

| Line 102: | Line 102: | ||

The TskVg-141 project draws roots from a 1970s Dnieguan project to develop a next-generation tank cannon. Originally proposed to be 130mm in diameter, the gun would be fitted to a number of armored brigades tanks, which would allow them to engage enemy armor at longer distances and deliver a much larger payload, pending mass adoption of an APFSDS round. With the adoption of the TskVg-124 in 1981, however, the project was scrapped, as it was believed the new tank was sufficient to fill all roles with its high-pressure 125mm gun. In 1982, the project was defended and effectively put to an end. However, in 1986, the Dnieguan Defense Ministry again contracted the same firms to design and draft the next generation of "heavy" tanks. | The TskVg-141 project draws roots from a 1970s Dnieguan project to develop a next-generation tank cannon. Originally proposed to be 130mm in diameter, the gun would be fitted to a number of armored brigades tanks, which would allow them to engage enemy armor at longer distances and deliver a much larger payload, pending mass adoption of an APFSDS round. With the adoption of the TskVg-124 in 1981, however, the project was scrapped, as it was believed the new tank was sufficient to fill all roles with its high-pressure 125mm gun. In 1982, the project was defended and effectively put to an end. However, in 1986, the Dnieguan Defense Ministry again contracted the same firms to design and draft the next generation of "heavy" tanks. | ||

The firms contracted and deign teams had initially planned to use the 130mm gun designed from the previous project. However, the Defense ministry specified the gun should offer at least a 20% increase in performance over the current M/76 Pzkn 12.5cm L/55 gun. The bore of the original high-pressure 130mm gun was bored out 10mm to fire a 140mm shell. Originally these bores proved to be able to fire the relatively low-speed HEAT and | The firms contracted and deign teams had initially planned to use the 130mm gun designed from the previous project. However, the Defense ministry specified the gun should offer at least a 20% increase in performance over the current M/76 Pzkn 12.5cm L/55 gun. The bore of the original high-pressure 130mm gun was bored out 10mm to fire a 140mm shell. Originally these bores proved to be able to fire the relatively low-speed HEAT and HE-MP payload warheads, but were identified to suffer major stress when firing the prototypical APFSDS projectiles. This resulted in the development of a dedicated 140mm smooth bore cannon by the Waffenfabrik Ongs Geschaft, a subsidiary of Husqvarna Sthal und vappenfabrik, A.G. of Skalgram, Uppsala, Dniegua, which offered a 40% increase in performance when firing Fin-Stabilized sabot ammunition due to a dramatically higher test pressure allowance. | ||

[[File:145mm APFSDS.png|left|thumb|The m/1074 Tarnskskottpatronen (TskPt) 14cm APFSDS shell compared to a 12.5cm M/993 TskPt APFSDS shell]] | [[File:145mm APFSDS.png|left|thumb|The m/1074 Tarnskskottpatronen (TskPt) 14cm APFSDS shell compared to a 12.5cm M/993 TskPt APFSDS shell]] | ||

The tank project posed several ambitious designs to meet several design goals. Colonel Bjorn Zicher of The Armor (Ret.), a famous tank designer in his own right, having worked on the | The tank project posed several ambitious designs to meet several design goals. Colonel Bjorn Zicher of The Armor (Ret.), a famous tank designer in his own right, having worked on the [[Denpryst Ikv-92]] Light tank and the TskVg-124, headed up the design team. The tank needed to be as fast as current main battle tanks while also armed well enough to engage any contemporary MAin Battle Tank at distances in excess of 2 kilometers, and protected along the front from contemporary anti-tank munitions, without increasing tank size greater than 10 percent in overall size. It had to be able to fire in 360 degrees while on the move, a lesson learned from the [[wpl|Stridsvagn 103|StTVg 103]], which had lackluster performance. The platform had to have the ability to survive an impact to the ammunition compartment, and should use a 3 or 4 man crew, with or without an autoloader. | ||

The original project goals were changed when it was understood that the mass of a 140mm cartridge would require an autoloader, as no single tanker could be expected to quickly load a 140mm shell, and continue to do so over the span of battle without significant fatigue. This caused great strain on the project teams, who, while having several designs of autoloaders, were unable to overcome the technical hurdles of mating the autoloader to the cannon positioned anywhere but centerline of the tank. Eventually recruiting Capital F. J. Lloyd of the Dnieguan Naval Arsenal at Chavporkal, designer of the 13cm Okan m/70, naval personnel were able to overcome the logistic hurdles for the deign team associated with loading to a different bore position on the move. | The original project goals were changed when it was understood that the mass of a 140mm cartridge would require an autoloader, as no single tanker could be expected to quickly load a 140mm shell, and continue to do so over the span of battle without significant fatigue. This caused great strain on the project teams, who, while having several designs of autoloaders, were unable to overcome the technical hurdles of mating the autoloader to the cannon positioned anywhere but centerline of the tank. Eventually recruiting Capital F. J. Lloyd of the Dnieguan Naval Arsenal at Chavporkal, designer of the 13cm Okan m/70, naval personnel were able to overcome the logistic hurdles for the deign team associated with loading to a different bore position on the move. In the time it took for the Navy to solve the issue, the designs had been streamlined and made more efficient, five of which were proposed, and eventually resulting in three possible designs. The first was a conventional 140mm smoothbore cannon in a remote turret mount, which would be raised and lowered by a remote operating arm to a height of up to 3.2 meters. When lowered, the tank was 2.3 meters. The second design was far more conventional, with the 140mm gun being encased in a traditional angular turret with 360 degree rotation, which had a height of 2.2 meters. The third design was reminiscent of case mate tank destroyers, made to circumvent the issue of the positional autoloader all together, to with a limited degree of fire (+12 to -8 degrees, with 6 degrees of gun traverse), but had the advantage of a low profile and very strong armor. | ||

The projects official introduction phase in | The projects official introduction phase in 1987-1989 saw all three testbeds built. The third prototype, while innovative and very well protected, was disqualified due to its mechanical complexity and inability to fire in a 360 degree arc while on the move-fitting, as it was only built as a test bed. Another problem was quickly discovered-The larger ammunition disallowed the tank from carrying large amounts of inboard ammunition, which posed an issue to the tanks combat ability against non-combat targets, due to the immature and under-developed HEAT and HE shells for the 140mm gun, in combat. While able to carry 36 rounds, with 22 "ready" in the autoloader, this was compared to the 46 of the TskVg-124. As a result of the lower amount of stored ammunition, the anti-armor focus of loaded munitions had diminished the tanks usefulness on the battlefield for firemissions other than anti-armor duties. A proposal was made to mount a commanders second turret armed with a 40mm Bofors cannon, to which one operational prototype was built, but was discarded later due to the height and bulk. Husqvarnas Cannon works stepped forward and offered the new m/80 Electrically fired, Cased-Telescoped 40mm Automatic cannon they had developed for the FyKVg-40-2 SPAAG variation shortly after this; The three prototypes were fitted with a 40mm coaxial electric-fired autocannon that was in development by Waffenfabrik Husqvarna for use against non-armored threats, allowing the TskVg-141 to carry its proposed standard load of anti-armor munitions. The autocannons were not fully integrated initially, instead being mounted in turret boxes connected to the tank via an independent hydraulic mount, containing its own AC motor and feed system, with the ammunition stored in the rear of the turret. | ||

As the competition went on, it was determined both tanks had merits, and the designers returned to combine elements into the same tanks. The eventual weapon chosen was a Ongs Waffenfabrik company submission, the m/91 14cm cannon. The final prototype utilized a traditional angular turret with firing controls and an auto loader system (Dubbed the "Navy Model" by some sources), as well as the mounting system for the 40mm gun from the same. Through a series of refinements, this became the TskVg-141. | As the design competition went on, it was determined both tanks had merits, and the designers returned to combine elements into the same tanks. The eventual weapon chosen was a Ongs Waffenfabrik company submission, the m/91 14cm cannon. The final prototype utilized a traditional angular turret with firing controls and an auto loader system (Dubbed the "Navy Model" by some sources), as well as the mounting system for the 40mm gun from the same. Through a series of refinements, this became the TskVg-141. | ||

==Production== | ==Production== | ||

| Line 124: | Line 124: | ||

! Bureau Number range || Dates of Production || Variations || Description | ! Bureau Number range || Dates of Production || Variations || Description | ||

|- | |- | ||

|80-000 to 08- | |80-000 to 08-044 || 1989-1992 || || Prototypes and testbed hulls produced for the Dnieguan Army. | ||

|- | |- | ||

|80-045 to 80-075 || 1993 || TskVg-141 ||Prototypical and pre-production models produced for the Dnieguan Army, and a single production SHORAD defense system (08-075) | |80-045 to 80-075 || 1993 || TskVg-141 ||Prototypical and pre-production models produced for the Dnieguan Army, and a single production SHORAD defense system (08-075) | ||

| Line 153: | Line 153: | ||

|- | |- | ||

|86-000 to 86-044 || Unknown ||TskVg-141U(B) || Prototype upgrades for TskVg-141K, eventually resulted in 2016 production of TskVg-141UK | |86-000 to 86-044 || Unknown ||TskVg-141U(B) || Prototype upgrades for TskVg-141K, eventually resulted in 2016 production of TskVg-141UK | ||

|- | |||

|87-000 on || Unknown ||TskVg-414UK || Production serials for the initial Dnieguan TskVg-141UK | |||

| | | | ||

|} | |} | ||

| Line 165: | Line 167: | ||

===Propulsion, Suspension, and Powerpack=== | ===Propulsion, Suspension, and Powerpack=== | ||

The multi-fuel diesel engine originally used by the TskVg was a Volvo 7120-RDN2. Displacing 38.88 cubic liters, the V-12, direct-injection, liquid cooled engine relied upon 90% diesel mixture propelling a 150mm bore 180mm of travel, with a 14:1:1, 4-stroke compression ratio. The power-pack consumed 215 grams of fuel per kilowatt per hour, enabling a paved-surface road speed of 78km/s, and an overland speed of 58 km/h. Later upgraded to the 7125-RDN5 Volvo engine, made specifically for the tank, the new engine increases power output by 10-15 percent with a 38.88 cubic liter displacement. | The multi-fuel diesel engine originally used by the TskVg was a Volvo 7120-RDN2. Displacing 38.88 cubic liters, the V-12, direct-injection, liquid cooled engine relied upon 90% diesel mixture propelling a 150mm bore 180mm of travel, with a 14:1:1, 4-stroke compression ratio. The power-pack consumed 215 grams of fuel per kilowatt per hour, enabling a paved-surface road speed of 78km/s, and an overland speed of 58 km/h. Later upgraded to the 7125-RDN5 Volvo engine, made specifically for the tank, the new engine increases power output by 10-15 percent with a 38.88 cubic liter displacement. The 7125-RDN5 increases bore stroke speed to 9.7 meters per second over the 7120s 8.7 meters per second, with a piston of a 150mm bore. A 380cc auxiliary power unit, based on a rotatory engine design, provides a power-dense option for the tanks operation in "engine off" mode, delivering 31.5kW, with a mean time between fail of 1140 hours. The 141UK version links the block 2 APU, a 405cc, 41.2kW rotary, to the transmission in a special crawling gear, allowing the tank to move along at a speed of approximately 8kph, albeit the tank is unable to operate any critical system besides the running gear, commander and drivers night vision, and, when activated, CBRN system when moving. In APU mode, the tank is silent at 40m, and produces little thermal signature. Plans are underway to replace the APU with a battery bank. | ||

A three pairs of road wheels of even spacing are enveloped by a relatively thick guarder track on either side, which may be folded out for access to the suspension. The hull of the tank measures 6.8 meters long and is 3.7 meters wide, while the gun forward makes the tank 10.7 meters long. The tanks is 2.26 meters from ground to the top of the turret, though with remote weapons stations the tank may measure to 2.65 meters tall. | A three pairs of road wheels of even spacing are enveloped by a relatively thick guarder track on either side, which may be folded out for access to the suspension. The hull of the tank measures 6.8 meters long and is 3.7 meters wide, while the gun forward makes the tank 10.7 meters long. The tanks is 2.26 meters from ground to the top of the turret, though with remote weapons stations the tank may measure to 2.65 meters tall. | ||

| Line 185: | Line 187: | ||

In addition, an fire suppression system within the crew and ammunition compartment exists and is automatically activated when a series of remote sensors detect flame. Blow-out panels are in place to protect the crew should the tank ammunition cook off. | In addition, an fire suppression system within the crew and ammunition compartment exists and is automatically activated when a series of remote sensors detect flame. Blow-out panels are in place to protect the crew should the tank ammunition cook off. | ||

==Operational History== | ==Operational History And Deployment== | ||

===Dniegua=== | ===Dniegua=== | ||

In 1996, Dnieguan armored forces entered the city of Angmar following a rebellion in the city. The first units in the city were Dnieuas 1st Armored Regiment, which at that time had 27 TskVg-141s in their pocession. They endured several attacks from Rocket-propelled grenades and preformed | ====Deployment==== | ||

Dniegua currently deploys the TskVg-141 as the standard Main Battle tank of its armored forces. The Dnieguan deployment consists of 31 tanks to a tank Battalion, with three companies of 9 line tanks and one command tank. These Armored Battalions are attached to Mechanized infantry Brigades. The Dnieguan Tank Brigade contains three Battalions of 31 tanks, for a total of 93 tanks to a Battalion. Each Tank Battalion also has three AVREs built on the TskVg-141 chassis. | |||

The Dnieguan marines operate Six independent tank Battalions of 31 tanks each, which are attached to respective Marine Brigades. the soul Dnieguan Marine Armored Brigade belongs to the 1st Dnieguan Naval Infantry Division, stationed in the capital city. | |||

The Dnieguan homeguard maintains, stores, and operates old models of all type for service use at a later time, and are typically organized into regional batteries of 9 tanks, which number 19 total batteries, and one active Tank Battalion of 31 TskVg-141Us. | |||

====Service==== | |||

In 1996, Dnieguan armored forces entered the city of Angmar following a rebellion in the city. The first units in the city were Dnieuas 1st Armored Regiment, which at that time had 27 TskVg-141s in their pocession. They endured several attacks from Rocket-propelled grenades and preformed extremely well, though none fired their 140mm cannons under order from command; the tanks were used essentially as very heavy infantry support vehicles, using their 40mm cannons and machine guns to supress and destroy rebel positions. | |||

[[File:Tskvg-141 in city.jpg|Left|thumb|Two Dnieguan [[Tarskvagn-124]] units provide overwatch as TakVg-141 "White 1", BuNo 80-041, the first production 141, enters the city arsenal.]] | [[File:Tskvg-141 in city.jpg|Left|thumb|Two Dnieguan [[Tarskvagn-124]] units provide overwatch as TakVg-141 "White 1", BuNo 80-041, the first production 141, enters the city arsenal.]] | ||

Latest revision as of 01:34, 4 July 2019

| Tarskvagn-141 TrsVg-141 | |

|---|---|

A TskVg-141UK of the Dnieguan Army | |

| Type | Main battle tank |

| Place of origin | Dniegua |

| Service history | |

| In service | 1998 |

| Used by | Dniegua |

| Production history | |

| Designer | Denpryst Auztofabriken |

| Designed | 1992 |

| Manufacturer | Denpryst Auztofabriken |

| Unit cost | $9,750,000 USD |

| Produced | Since 1999 |

| No. built | 2500-3,200 (Estimated) |

| Specifications | |

| Weight | 59.2 tons TsKvg-141A 61.2 Tonnes TskVg-141K 63.5 tonnes TskVg-141U TskVg-141UK is estimated at 66.2 tonnes Tskvg-141V 62.2 tonnes |

| Length | 6.8m (chassis) 10.2m (gun forward) |

| Width | 3.7 m |

| Height | 2.26m Top of weapons mount increases height to 2.42m |

| Crew | 3 |

| Armor | Laminated steel/ceramic/composite mixture with ERA blocks, along with modular armor packages |

Main armament | x1 Husqvarna TaSk 14cm L/45 Cannon with 32 rounds (26 APFSDS, 6 HEAT) Ong Waffenfabrik m/1156 14cm TarnskvarnKannone L/50 |

Secondary armament | x1 40mm cannon wih 226 rounds of HE or APFSDS 6.5mm Machine Gun (Coax) Roof mount of 14.5mm Machine Gun or 25mm M/26T |

| Engine | Skab-Volvo 12 Cylinder Diesel developing 1080kW TsKVg-141UK Volvo 7125-RDN5 developes 1125kW and 4,000nM Torque |

| Power/weight | 16.7 kW/t |

| Transmission | Automatic with six forward and three reverse gears |

| Suspension | hydropneumatic |

| Fuel capacity | 1,300 ℓ (1,700 ℓ with fuel drums) |

Operational range | 500 km (640 km with fuel drums) |

| Speed | 76 km/h |

The Tarskvagn-141 (TskVg-141) is a domestically produced Main Battle Tank from Dniegua. Intended to supplement the Tarskvagn-124 in armored units, and later replace it all together, the Tskvg-141 represents a major leap in armored capability and design in the 20th century. Commonly called the T-vagn, the TskVg-141 is armed with a 140mm L/45 smoothbore gun with 32 rounds, as well as a Coaxial 40x364mm cannon. The commanders station is provided with a shielded sled mount, allowing all AEN 4589 standard light weapons to be mounted.

The TskVg-141 development started in the late 1980s as a plan to defeat modern evolving composite armors from longer ranges. Economic situations and issues slowed development as funds were diverted from armored projects to stop-gap solutions such as gun-launched anti-tank guided missiles (GLATGMs), which ensured little (if any) development took place through most of the early 1990s. The project was revitalized in the mid 1990s as it became apparent that current production MBTs would be unable to reliably fight and defend from next-generation main battle tanks. Prototypes entered trials in 2002, and the first vehicles were adopted in 2004. Today, Dniegua is the largest operator of the TskVg-141 with 1,600 in service, with plans to acquire over 1,000 more within the next decade.

History

The TskVg-141 project draws roots from a 1970s Dnieguan project to develop a next-generation tank cannon. Originally proposed to be 130mm in diameter, the gun would be fitted to a number of armored brigades tanks, which would allow them to engage enemy armor at longer distances and deliver a much larger payload, pending mass adoption of an APFSDS round. With the adoption of the TskVg-124 in 1981, however, the project was scrapped, as it was believed the new tank was sufficient to fill all roles with its high-pressure 125mm gun. In 1982, the project was defended and effectively put to an end. However, in 1986, the Dnieguan Defense Ministry again contracted the same firms to design and draft the next generation of "heavy" tanks.

The firms contracted and deign teams had initially planned to use the 130mm gun designed from the previous project. However, the Defense ministry specified the gun should offer at least a 20% increase in performance over the current M/76 Pzkn 12.5cm L/55 gun. The bore of the original high-pressure 130mm gun was bored out 10mm to fire a 140mm shell. Originally these bores proved to be able to fire the relatively low-speed HEAT and HE-MP payload warheads, but were identified to suffer major stress when firing the prototypical APFSDS projectiles. This resulted in the development of a dedicated 140mm smooth bore cannon by the Waffenfabrik Ongs Geschaft, a subsidiary of Husqvarna Sthal und vappenfabrik, A.G. of Skalgram, Uppsala, Dniegua, which offered a 40% increase in performance when firing Fin-Stabilized sabot ammunition due to a dramatically higher test pressure allowance.

The tank project posed several ambitious designs to meet several design goals. Colonel Bjorn Zicher of The Armor (Ret.), a famous tank designer in his own right, having worked on the Denpryst Ikv-92 Light tank and the TskVg-124, headed up the design team. The tank needed to be as fast as current main battle tanks while also armed well enough to engage any contemporary MAin Battle Tank at distances in excess of 2 kilometers, and protected along the front from contemporary anti-tank munitions, without increasing tank size greater than 10 percent in overall size. It had to be able to fire in 360 degrees while on the move, a lesson learned from the Stridsvagn 103|StTVg 103, which had lackluster performance. The platform had to have the ability to survive an impact to the ammunition compartment, and should use a 3 or 4 man crew, with or without an autoloader.

The original project goals were changed when it was understood that the mass of a 140mm cartridge would require an autoloader, as no single tanker could be expected to quickly load a 140mm shell, and continue to do so over the span of battle without significant fatigue. This caused great strain on the project teams, who, while having several designs of autoloaders, were unable to overcome the technical hurdles of mating the autoloader to the cannon positioned anywhere but centerline of the tank. Eventually recruiting Capital F. J. Lloyd of the Dnieguan Naval Arsenal at Chavporkal, designer of the 13cm Okan m/70, naval personnel were able to overcome the logistic hurdles for the deign team associated with loading to a different bore position on the move. In the time it took for the Navy to solve the issue, the designs had been streamlined and made more efficient, five of which were proposed, and eventually resulting in three possible designs. The first was a conventional 140mm smoothbore cannon in a remote turret mount, which would be raised and lowered by a remote operating arm to a height of up to 3.2 meters. When lowered, the tank was 2.3 meters. The second design was far more conventional, with the 140mm gun being encased in a traditional angular turret with 360 degree rotation, which had a height of 2.2 meters. The third design was reminiscent of case mate tank destroyers, made to circumvent the issue of the positional autoloader all together, to with a limited degree of fire (+12 to -8 degrees, with 6 degrees of gun traverse), but had the advantage of a low profile and very strong armor.

The projects official introduction phase in 1987-1989 saw all three testbeds built. The third prototype, while innovative and very well protected, was disqualified due to its mechanical complexity and inability to fire in a 360 degree arc while on the move-fitting, as it was only built as a test bed. Another problem was quickly discovered-The larger ammunition disallowed the tank from carrying large amounts of inboard ammunition, which posed an issue to the tanks combat ability against non-combat targets, due to the immature and under-developed HEAT and HE shells for the 140mm gun, in combat. While able to carry 36 rounds, with 22 "ready" in the autoloader, this was compared to the 46 of the TskVg-124. As a result of the lower amount of stored ammunition, the anti-armor focus of loaded munitions had diminished the tanks usefulness on the battlefield for firemissions other than anti-armor duties. A proposal was made to mount a commanders second turret armed with a 40mm Bofors cannon, to which one operational prototype was built, but was discarded later due to the height and bulk. Husqvarnas Cannon works stepped forward and offered the new m/80 Electrically fired, Cased-Telescoped 40mm Automatic cannon they had developed for the FyKVg-40-2 SPAAG variation shortly after this; The three prototypes were fitted with a 40mm coaxial electric-fired autocannon that was in development by Waffenfabrik Husqvarna for use against non-armored threats, allowing the TskVg-141 to carry its proposed standard load of anti-armor munitions. The autocannons were not fully integrated initially, instead being mounted in turret boxes connected to the tank via an independent hydraulic mount, containing its own AC motor and feed system, with the ammunition stored in the rear of the turret.

As the design competition went on, it was determined both tanks had merits, and the designers returned to combine elements into the same tanks. The eventual weapon chosen was a Ongs Waffenfabrik company submission, the m/91 14cm cannon. The final prototype utilized a traditional angular turret with firing controls and an auto loader system (Dubbed the "Navy Model" by some sources), as well as the mounting system for the 40mm gun from the same. Through a series of refinements, this became the TskVg-141.

Production

Production is preformed at three major manufacturers, with final component construction and assembly preformed at the Dnieguan state-owned Heavy Vehicle plant, Denpryst Auztofabriken, in Denpryst. Production from 2008 onwards had been preformed at the 37,200 square meter H.V. Gustav factory. Components are provided from Volvo-Skabb, who produce the 7120-RDN2 from their common Heavy Propulsion Plant in Upsalla. Guns and armament subsystems are produced by Husqvarna Wappenfarik under contract from the Dnieguan V.K. Warsalla Artillery Arsenal in Mannheim. Chassis and turrets are produced in Ong by Marskov Heavy Industries; turrets are produced by the Bofors subsidiary since 2011. Electronic subsystems are overwhelmingly produced by Scantronic IDS and Erricson Microwave of Mamo. Armor is produced at Denpryst.

Initial prototype production began in 1989. The first 4 prototypes, BuNo 80-001 to 80-004, were delivered July of 1990. Sixteen further preproduction prototypes, all produced at Denprysrt, were produced in 1991-1992FY. BuNos 80-020 to 80-044 were all hull prototypes produced for a common chassis project, including two SPGs, an ARV, a SPAAG, and a heavy infantry carrier; these hulls were used for weapons testing, resistance testing, and troop trials. BuNo 80-045 to 80-073 were delivered as part of "Series White" to the Dniegaun 1st Armored Brigade, 1st Regiment, which composed 27 line units, with the four command tanks being Tarnskvagn 124KBs common to the Regiment previously. Following successful troop trials, production was approved.

All Tarnskvagn 141 series main battle tanks utilize 5-digit bureau numbers, consisting of series (8x) and 999 unit batches.

| Bureau Number range | Dates of Production | Variations | Description | |

|---|---|---|---|---|

| 80-000 to 08-044 | 1989-1992 | Prototypes and testbed hulls produced for the Dnieguan Army. | ||

| 80-045 to 80-075 | 1993 | TskVg-141 | Prototypical and pre-production models produced for the Dnieguan Army, and a single production SHORAD defense system (08-075) | |

| 80-078 to 81-044 | 1995-1996 | First series production vehicles for the Dnieguan Military. Suffered dramatic issues due to hand fitting and industry tool-up. | ||

| 80-076, 80-077, 81-046-81-055 | 1996(?), 1997 | BrgVp-4 ARV/CEV | Hulls for troop trials; hull 80-077 was the first combat destroyed TskVg hull. | |

| 81-056 to 81-242 | 2000-2001 | TskVg-141A | Bureau Numbers allocated for 186 TskVg-141A vehicles. | |

| 81-250 to 81-860 | 2003 to March 2004 | TskVg-141A | Series Production. | |

| 82-000 to 82-124 | September 2003 to September 2004 | TskVg-141V | Dnieguan Marine series production | |

| 81-860 to 81-922 | July to October 2004 | BrgVP-4 and PjgVG-4 | Production BrgVP ARV and CEVs | |

| 83-000 to 83-093 | 2005 | TskVg-141A | Series Production | |

| 83-094 to 83-279 | 2006 | TskVg-141A | Series Production | |

| 82-125 to 82-249 | November 2006 to December 2007 | TskVg-141V | Naval Series Production | |

| 84-000 to 82-372 | October 2008 to 2012 | TskVg-141K | Initial order of TskVg-141K tanks | |

| 82-250 to 82-343 | March 2009 to 2014 | TskVg-141V2 | Dnieguan Naval Production | |

| 84-373 to 84-670 | 2013 | TskVg-141K | Series Production | |

| 86-000 to 86-044 | Unknown | TskVg-141U(B) | Prototype upgrades for TskVg-141K, eventually resulted in 2016 production of TskVg-141UK | |

| 87-000 on | Unknown | TskVg-414UK | Production serials for the initial Dnieguan TskVg-141UK |

Design

Overview

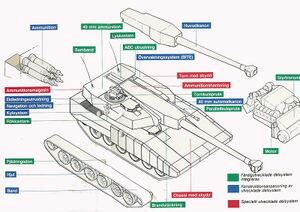

The Tarskvagn-141 follows the traditional role of modern main battle tanks by being relatively mobile and compact while being well armed and armored. With a maximum combat weight of 62.6 tonnes, the tank has a maximum speed of 70km/h and a range of 500 kilometers. The 140mm L/45 cannon is a dramatic increase in what was previously considered traditional main battle tank armament in size and thus volume, resulting in a carrying capacity of 24 rounds of ready main gun ammunition, and 16 in stowage. In order to engage what Dniegua terms "secondary mission targets", which induces non-armored or non critical structures, light armor vehicles, or infantry formations, The 40mm Cannon sits on the side of the turret loaded with 260 40mm rounds in a dual feed system, loaded with 60 APFSDS projectiles and 200 HE. These are selected from their respective feed trays by a toggle switch. Due to the gas-actuated, electrically fired, closed bolt action of the 40mm m/80 Autocannon, the action of switching ammunition types requires the firing of the system. Autocannon ammunition was originally expelled from the underside of the weapons module on early models prior to hull integration, but are now expelled from an upward sloping surface leading to the rear of the turret, and are thrown free of the turret by extraction inertia. The 140mm cannon has been shown to penetrate up to 850mm RHAe at 2.5km distance, while the HEAT shell has been estimated to be able to defeat over 1400mm RHA. The commanders station as of the 141U version contains a day/night weapons sight in a remote mount, and is usually armed with a 14.5mm or 12.77 Machine gun, buy may also be armed with the M/26T, a 25x59mm light cannon system able to engage infantry, equipment, and structures out to 2,200m. When in the MIDGUARD mount, the M/26T is often paired with a Ksp-58T 6.5mm Machine gun with 250 rounds.

.

In 2009 the M1401 Knozka-G shell entered service. A 125mm guided missile encased in a guiding sabot, the M1401 fires a guided, SACLOS/ACLOS dual mode projectile using technology developed from the PSO-91 AADS. The commander and gunners weapon sights both act as programming optics for the guided munition, which is selected by turning the commanders dial to the number 4 position. When ready, the commanders station emits an audible buzz, and the shell is fired. A 1.2m long projectile, weighing 38.5 kilograms with an explosive mass of 6.2kg in a 14.5kg warhead, the missile reaches a maximum speed of 360m/s and has a maximum range of 8 kilometers. It, like the PSO-91, utilizes a multi-mission profile with direct attack or top attack modes, and is able to penetrate the top armor of MBTs.

Propulsion, Suspension, and Powerpack

The multi-fuel diesel engine originally used by the TskVg was a Volvo 7120-RDN2. Displacing 38.88 cubic liters, the V-12, direct-injection, liquid cooled engine relied upon 90% diesel mixture propelling a 150mm bore 180mm of travel, with a 14:1:1, 4-stroke compression ratio. The power-pack consumed 215 grams of fuel per kilowatt per hour, enabling a paved-surface road speed of 78km/s, and an overland speed of 58 km/h. Later upgraded to the 7125-RDN5 Volvo engine, made specifically for the tank, the new engine increases power output by 10-15 percent with a 38.88 cubic liter displacement. The 7125-RDN5 increases bore stroke speed to 9.7 meters per second over the 7120s 8.7 meters per second, with a piston of a 150mm bore. A 380cc auxiliary power unit, based on a rotatory engine design, provides a power-dense option for the tanks operation in "engine off" mode, delivering 31.5kW, with a mean time between fail of 1140 hours. The 141UK version links the block 2 APU, a 405cc, 41.2kW rotary, to the transmission in a special crawling gear, allowing the tank to move along at a speed of approximately 8kph, albeit the tank is unable to operate any critical system besides the running gear, commander and drivers night vision, and, when activated, CBRN system when moving. In APU mode, the tank is silent at 40m, and produces little thermal signature. Plans are underway to replace the APU with a battery bank.

A three pairs of road wheels of even spacing are enveloped by a relatively thick guarder track on either side, which may be folded out for access to the suspension. The hull of the tank measures 6.8 meters long and is 3.7 meters wide, while the gun forward makes the tank 10.7 meters long. The tanks is 2.26 meters from ground to the top of the turret, though with remote weapons stations the tank may measure to 2.65 meters tall.

Electronic Systems

Present in all models since 2009 are variations of the Ebrus-U fire control system. This multi-plane, multi-mode fire control system utilizes the Stonsa-ER Long-aperture Day/Nigt sight, the Atlus-G3 periscope Day/Night wide-aperture sight, the Kestril-2500 meteorological station, a series of SAAB EPM FLIR cameras, and the Ballast-T ballistic computer to plot fire control data for the commander and gunner. The system is mated to the Lambda gyroscopic stabilization and plane control system, which provides 360 degree full gun stabilization for the 140mm cannon. The accessory Kedar-40 Fire Control unit for the 40mm operates alongside this system, and may be matted to the 1L112 Fire Control Radar director, which allows the programming of the Ek.Patt. m/1 HE-MP munition, enabling air burst and programmed munition delivery for the 40mm system. During daytime this system allows engagement of targets to 8+ km distance, and 2000+m in night time battle conditions. The gunners sight has a 3x, 6x, 10x, and 14x modes in day/night, and a 2x, 10x, and 14x in thermal scan modes. The Commanders UL-4 panoramic sight uses 7 periscopes, with a digital and electronic zoom of 1.1-10x. A Husqvarna Tuke-14 autoloader and automatic wedge provide the loading and fire control for the tank. Both the gunner and commander are provided with controls to the autoloader, which is able to rotate 26 degrees per second; the cartridge cassette is composed of a skeletonized aluminium body to save weight. Loading is accomplished by hydraulic force, and depending on the angle of the gun, typically takes between 6.8 and 11.4 seconds, with an average of 18 seconds needed to change ammunition types. 24 ready rounds are stowed in the carousel, generally 16 APFSDS, 6 HEAT, and 2 HE-MP.

Cover and Concealment

The TskVg-141 has an especially low-profile, allowing for excellent hull-down positioning and camouflage. Painted in the standard M/90 Fractile camouflage pattern most generally, the tank has a disruptive profile, creating, with proper cover and concealment, a visual effect similar to that from fragmentation, reducing the time of recognition. A pair of two eight-barrel smoke discharges create a large area of smoke around the tank, concealing it from thermal view. In addition, a remote smoke generator can be activated by the driver, which creates a thick discharge of smoke in driving.

.

Protection

In addition to thick armor, Since the TskVg-141K, all tanks are equipped with the Scantronic ITDS-D softkill munitions which provides the ability to preform passive of defeat incoming anti-tank missiles. The systems impede the function of guidance systems of some semi-active control line-of-sight (SACLOS) wire and radio guided anti-tank missiles and infrared homing missiles. This system works by emitting a massive, condensed infrared signal to confuse the infrared homing seeker of an anti-tank guided missile (ATGM), and uses a pair of too infrared diodes, one on each side of the main gun, which continuously emit a pulsed-infrared jamming signal when an incoming ATGM has been detected. Eight twin-barrel 81mm smoke screen grenade projectors are located on the tank, which emit a cloud of smoke opaque to laser guidance systems, with a bloom time of 3 seconds and a typical lifespan of 15-20 seconds. If enabled, According to those familiar with the system, the ITDS-D system can also locate the area within 3.5–5 degrees where the laser originated from and automatically slew the main gun to it, so that the tank crew can return fire and so that the stronger frontal turret armour is facing it. The sensors have a 360 degree, -5 and +25 degree azimuth. The TskVg-414UK improvement package shown in 2014 implements the Scantronic Omnibus Hardkill system, which protects the sides and rear of the tank using five munition dispensers, able to intercept munitions moving at between 40 and 345m/s. An upward-facing hardkill system, the Scantronic Sarcophagus Hemisphere Protection Complex has been pictured on some operational Tsk-141UKs, which consists of two, tri-tube projectors, containing a single, twin-charged munition with 12 submunition charges each, in a turret-top discharer, slaved to the vehicle's soft kill APS. The barrels are angled at 75, 85, and -15 degrees from midline, and provide a theoretical intercept envelope of about 45 degrees. The chargers fly about 15 meters from the tube before firing each of their cluster charges in the path of the detected warhead.

The Tskvg-141 utilizes an Ericsson-AB built Rosentka-A NBC protection system, designed by Dnieguas Chemical Crops. The system utilizes a bank of mass air flow filters providing an overpressure of clean, breathable air at a rate of 10 cubic meters per minute at a positive pressure of 2.52 bar. The tank is equipped with a DAZ-3 CBRN digital atmospheric laboratory station which provides warning to the tanks commander.

In addition, an fire suppression system within the crew and ammunition compartment exists and is automatically activated when a series of remote sensors detect flame. Blow-out panels are in place to protect the crew should the tank ammunition cook off.

Operational History And Deployment

Dniegua

Deployment

Dniegua currently deploys the TskVg-141 as the standard Main Battle tank of its armored forces. The Dnieguan deployment consists of 31 tanks to a tank Battalion, with three companies of 9 line tanks and one command tank. These Armored Battalions are attached to Mechanized infantry Brigades. The Dnieguan Tank Brigade contains three Battalions of 31 tanks, for a total of 93 tanks to a Battalion. Each Tank Battalion also has three AVREs built on the TskVg-141 chassis.

The Dnieguan marines operate Six independent tank Battalions of 31 tanks each, which are attached to respective Marine Brigades. the soul Dnieguan Marine Armored Brigade belongs to the 1st Dnieguan Naval Infantry Division, stationed in the capital city.

The Dnieguan homeguard maintains, stores, and operates old models of all type for service use at a later time, and are typically organized into regional batteries of 9 tanks, which number 19 total batteries, and one active Tank Battalion of 31 TskVg-141Us.

Service

In 1996, Dnieguan armored forces entered the city of Angmar following a rebellion in the city. The first units in the city were Dnieuas 1st Armored Regiment, which at that time had 27 TskVg-141s in their pocession. They endured several attacks from Rocket-propelled grenades and preformed extremely well, though none fired their 140mm cannons under order from command; the tanks were used essentially as very heavy infantry support vehicles, using their 40mm cannons and machine guns to supress and destroy rebel positions.

The Tarskvagn 141s first major combat was with Dnieguan Naval Infantry units operating oversees with peacekeeping forces in various conflict zones. For the most part, these tanks acted as mobile fire support for infantry units and defensive maneuver elements, firing on fixed position, hardened structures and vehicles at extended range. Proving durability, the Tvagn 141 proved suitability by withstanding a large number of impacts from anti-tank rockets and missiles, including a friendly fire incident with a Pskott. M/48.

Variants

Dniegua

Tarnskvagon 141

The initial pre-production variation of the TskVg-414, introduced in the early 2000s. This version utilized an outboard 40mm cannon, easily recognizable by its weapons box and more narrow turret. 93 of these vehicles were built and suffered dramatic service issues due to had-fitting of the turret from Bofors. Weapons system integration and programming had to be preformed at the factory specific to each vehicle, due to the variances with each turret. 40mm guns were fixed to either side of the turret depending on the necessary geometry of the turret. In all, 76 were fitted with the gun to the Left of the turret, and 17 to the Right. In production for 1 year as tooling was finished. Only one tank still exists at the Nationel Pansarmeuset in Angmar, and three turrets on display. All hulls were refitted for the TskVg-141A.

Tarskvagon 141A

Initial mass production version. 40mm cannon integrated to Left side of the turret, immediately to the left side of the gun, with the Taiga-6 FCS. Production started in 2003, and deliveries began later that year. 186 produced new and 93 converted from the pre-production models; some literature classified these as the 141AN and 141AO, though it is unclear if these are formal Dnieguan army designations.

Tarskvagon-141K

Upgrade package introduced in 2009. Includes new Day/night sights, FLIR, and an option to mont a commander RWS station able to mount a variety of machine guns. The Santronic Electro-optical ITDS-T Jamming system. The Ebrus-6 Fire Control system replaces the Taiga-6 system, allowing for the firing of the Reflex-40 programmable HEMP 40mm munition from the m/80 cannon.

.

Tarnskvagon 141V

Dnieguan Naval Infantry version of the Tarnskvagon-141. Versions are designated "V1" and "V2"; the V1 variation, introduced in 1999, is based on the A series of Tarnskvagon 141, with later serial upgrades and improvements for the Navy. Externally identifiable by the presence of a rear mounting bracket for a swim kit and usually in naval infantry pattern steel camouflage. The V series features a series of lightening improvements, including a Inconel barrel sleeve, the tank has a dry weight of 2.8 tonnes less than that of the 141A. Naval infantry frequently load only the autoloader to 20 main gun rounds. The 141V2 improvement cluster was a late service life upgrade for the 141A, incorporating the 141Ks unified sights, soft kill systems, and other control system. The 141V2 included hardkill systems integrated into the turret roof, though the type remains unknown. The V2 also has a series of turret brackets, which allow the Dnieguan Naval Infantry dismounts to use the standard BAZ-94 clip on their webbing to snap themselves safely to the turret.

Tarnskvagon-141U

Specialist version of the 141A that included a series of mid-life upgrades and an applique, modular armor outboard set. 44 were built in total for testing and equipped an experimental tank Battalion. All units withdrawn from service. Lessons learned created the TskVg-141UK.

Tarnskvagon-141UK

Introduced in 2016, the Tarnskvagon-141UK serves as the latest and most modern of the Tarnskvagon-141 family, and represents a major overhaul of the fleet. A new autoloader and new L/50 14cm cannon reduce time to load by 12.5 percent, and have dramatically increased the mean time between failure. An all-inconel thermal sleeve taken from the 141V replaces the previous thermal sleeve in a re-manufactured turret, with integration of both hard and soft-kill systems. The 141UK includes a new standard remote weapons mount, controllable by both the gunner and the loader, and includes a series of external a/v cameras for the driver station, which includes a new GPS and IFF transponder. The drivers data link may now also be connected into the commanders battle network, allowing the commander to replay information to the driver via the internal computer system. A new, dedicated engine replaces the previous model with a more power-dense APU, with increased fuel economy and a longer mean time between failure. A new FCS, allowing the firing of new, programmable HE and specialty ammunition's is now included. The cost of a new TskVg-141UK is estimated at $7,500,000 Dnieguan Kroner (About $5,100,000 USD) new, but using old hulls the overall cost is $4,200,000 Kroner, about 2,850,000 USD.

Operators

![]() Dniegua - Total: 2,100 in active service, several hundred in service for some 2,700 total assumed.

The standard Armored Core Main Battle Tank of the Dnieguan Armed Forces.

Dniegua - Total: 2,100 in active service, several hundred in service for some 2,700 total assumed.

The standard Armored Core Main Battle Tank of the Dnieguan Armed Forces.

Dnieguan Army

- Arms the Seven Dnieguan Armored Brigades with 93 vehicles each, and the seven integrated armored battalions in the Dnieguan mechanized infantry brigades, for a total of 868 in Army service, plus 62 training tanks.

- At least five Battalions worth of 141UKs have been delivered as of September, 2018.

- Arms the Seven Dnieguan Armored Brigades with 93 vehicles each, and the seven integrated armored battalions in the Dnieguan mechanized infantry brigades, for a total of 868 in Army service, plus 62 training tanks.

Dnieguan Naval Infantry

- The six Tank Battalions of the Dnieguan Marines operate 31 units TskVg-141V vehicle each, while the 1MEU operates one full tank Brigade of 93, for a total of 279 TskVg-141Vs and 12 training tanks. The Marines operate the Ikv-121 light tank in companies contained within their mechanized and light infantry units.

Dnieguan Homeguard

- The Dnieguan homeguard has an active component of 202 TskVg-141s and some 686 old models in storage. These are mixed models, ranging from 141As to 141U models.

Dnieguan Airforce

- Some tanks have been seen in Dnieguan Airforce color schemes, though it is unclear if these are a propaganda tool or are actually used.