Cordoba TFV-400

| Cordoba TFV-400 | |

|---|---|

Cordoba TFV-400 in demonstration livery | |

| General information | |

| Type | Widebody twinjet airliner |

| Manufacturer | Cordoba Commercial Aerospace |

| Designer | Cordoba Aerospace |

| Status | In service, in production |

| History | |

| Manufactured | 2011–present |

| Introduction date | January 4, 2014 |

The Cordoba TFV-400 is a family of widebody twinjet commercial airliners produced by Cordoba Commercial Aerospace. Initial variants are designed to serve the high-capacity long-haul market with seating capacities between 370-430 passengers and a maximum range between 8,200 and 9,500 nautical miles (15,200 to 17,590 km). It is the first of the "-400" series of Cordoba aircraft, incorporating all-new as well as improved features from legacy aircraft. The type is distinguished by its circular fuselage cross-section, raked folding wingtips, six-wheel main landing gear, and toothed engine ducts, and was designed with input from several major airlines.

The aircraft's initial designation during development was the TFV-4XX, until receiving its formal designation in 2009. The first basic airframe was rolled out in December of 2010, with first test flights occurring in March of 2011. Despite initial delays due to changing airline requirements, improvements in the design regime resulted in a net loss of only two months, and the first aircraft entered service with Phoenician Airways in January 2014. Among the new features introduced in the TFV-400 is the use of an all-electric system eliminating engine bleed air, improved acoustic dampening internally and externally, significantly increased use of composites in construction, the use of geared turbofans for power, and the use of electric wheel hub motors for taxiing to the runway.

History

By the late 1990s, Cordoba Aerospace was embroiled in an intense competition against Boeing and other airline manufacturers for the rapidly-growing long-haul market, which Boeing had achieved a significant advantage in following the launch of the 777 in 1994. Against Cordoba's smaller and older twinjets, the Boeing 777 had greater range, greater payload, and most importantly, reduced operating costs, and the type was rapidly adopted at the cost of Cordoba's own smaller TFV-340. In response, Cordoba announced the development of a stretched variant of the TFV-340, increasing passenger capacity while relying on a new engine option to improve efficiency. While the TFV-340NG never achieved the same success as the newer 777, Cordoba was able to successfully market the aircraft on the basis of its commonality with existing TFV-340s in inventory, maintaining a steady stream of orders into the early 21st century.

The next stage of the competition began in the mid-2000s, as Boeing announced plans for the 787 Dreamliner, a mid-size widebody twinjet with greater efficiency than the 777, and which would impact sales of the TFV-300 and smaller variants of the TFV-340NG. The improved TFV-300X had just been released with new engine options, but was still based on an older airframe and airlines gravitated toward the newer 787. As a result, Cordoba's management announced the development of the -400 series in late 2007, to be inaugurated with the TFV-4XX, a long-haul airliner designed to compete with the Boeing 747, a market Cordoba had traditionally not contested.

The -400 series itself was the result of several abortive programs in the mid-1990s and early 2000s to develop all-new airliners, which were shelved for various political and economic reasons in favor of improved variants of existing aircraft. With competitors moving to develop all-new aircraft, it had become clear that Cordoba would be required to answer with its own all-new designs, which would take the form of the -400 series, expected to fully replace all previous types once fully established and allow Cordoba to compete in most market segments with a new stable of designs.

Development work began in 2008 with cooperative input from Phoenician Airways, Mediterranean Skies, and several other foreign carriers to determine design priorities. The sudden economic downturn of the late 2000s caused a reassessment of the design in light of new financial pressure on the airlines, resulting in several delays. Nevertheless, the first airframe was rolled out in late 2010 at Cordoba's development plant in Dakar, with flight testing commencing the following year once engine tests on the new GTxa-450B engines were competed. Despite efforts to correct the problem, the initial airframe was some 3,000 kg (6,600 lbs) overweight, although later airframes incorporated redesigns and were slightly underweight when delivered. Flight testing proceeded generally smoothly at Henderson Field through mid-2013, when the TFV-400 received type certification and completed individual engine certification programs.

The first production model, airframe number 006, was delivered to Phoenician Airways in September 2013, flying its first commercial flight on January 4, 2014. By this time, Cordoba had recorded 320 orders for the base 400α and as well as 150 for the stretched 400β. In April 2014, Cordoba announced new orders totaling 120 new aircraft from several airlines, including Imperial Airways and Transoceanic Travel.

Design

Airframe

Great emphasis was placed on improved fuel economy over previous designs, with rising fuel costs putting pressure on airlines to reduce seat costs per kilometer and to control fuel expenditures. As a result, the TFV-400 is 80% composite by volume and 52% composite by weight, with the balance composed of titanium, aluminum-lithium alloys, and steel. The primary composite is carbon-fiber-reinforced polymer. Aluminum is used for leading edges and other structures expected to possibly bear the brunt of an impact for birdstrike protection, with titanium used for structural fasteners and carbon fiber for large sections of the fuselage and non-articulated sections of the wings.

Previous -300 series Cordoba airliners generally used no more than 10% composites by weight, representing a significant increase. In order to assuage customer and consumer concerns about the reliability and safety of composite materials, Cordoba developed a new maintenance system and training program for aircraft technicians, including improved detection procedures for stress and weakening components and a new extended support program for life-cycle maintenance.

In order to improve fuel economy, the TFV-400 incorporates Advanced Laminar Flow Control (ALFC), a system designed to reduce turbulence over the wings and control surfaces, reducing drag and fuel burn. The system takes the form of a series of small holes drilled into the leading edges of the stabilizers, allowing a portion of the air to flow directly through the stabilizer rather than being diverted around it, as well as further optimized aerodynamic surfaces including raked wingtips. Previous problems clogging that had prevented the implementation on earlier airliners were resolved through the use of a compressed air system to purge any clogged vents without adding excessive weight or complexity.

The increase in wingspan to 72 m (236 ft) led to concerns that the TFV-400 would be uprated to ICAO Category F, the same as modern superjumbo airliners, which would limit its ability to serve smaller airports with sufficient weight but not space to accommodate such an aircraft. As a result, a wing-folding mechanism was implemented, allowing the outer 3.6 m (12 ft) of the wings to be folded upward on the ground and allowing the aircraft to retain Category E classification while taxiing and at the gate. In order to avoid any increases in maintenance costs and to keep weight penalties to a minimum, the mechanism was simplified and does not affect any of the control surfaces or fuel storage. As part of standard safety testing, the TFV-400 is rated to fly with one or both flaps in the folded position in the event of failure.

Avionics

Like the more recent Cordoba designs of the -300 series as well as a number of foreign designs, the TFV-400 is a fly-by-wire design using a fiber-optic network and glass cockpit to transmit control data throughout the aircraft. The new cockpit design uses six LCD screens to replace the conventional array of analog gauges used by previous-generation aircraft and an improvement over the four-screen glass cockpit used in the TFV-340NG. Two heads-up display units also provide information to the pilots, reducing the need to divert attention to the instruments. Computerized functions are handled by a centralized system composed of modular line replaceable units, reducing maintenance time and cost.

The cockpit also features connections to interface with modern electronic flight bags to automatically generate a flight plan as well as a terrain and weather map for the expected course. As with previous Cordoba aircraft, the TFV-400 employs a yoke, rather than a side-stick configuration. An optional forward-looking infrared system is available that allows improved visibility through clouds, projected onto the aircraft's HUD for pilot use.

The TFV-400 is the first Cordoba aircraft to be fitted from the factory with onboard wireless internet capability, although receiver antennae for satellite or ground-based transmissions beyond standard ACARS are the responsibility of individual airlines to install. Provisions exist for the installation of flush satellite and air-to-ground antennas, rather than the external units used on legacy aircraft which increase drag. Onboard electronics are designed to be insulated against electronic emissions by consumer devices as well as to address cybersecurity concerns.

Engines

During the initial design phase, the design was expected to use a variant of the CRxa-305-500A turbofan developed for the RTS-225 Cronus strategic airlifter, but airlines pushed for the inclusion of new engine options, especially more fuel efficient ones. As a result, the final competition was between the Cordoba Turbomechanics GTxa-400-470B, the Elissa-Arishat ANF-390-465A, and the General Electric GE90-110B4 for the initial TFV-400α. In the end, due to airline pressure, all three engines were approved for use after specified modifications were made to ensure compatibility. Most initial orders have favored the GTxa-400-470B, a geared turbofan designed specifically for use on the TFV-400. Engine thrust for the TFV-400 was specified at 470 kN (110,000 lbf), while stretched and longer-ranged variants are expected to have engine specifications over 515 kN (116,000 lbf).

Unlike previous aircraft, the TFV-400 does not use engine bleed air to cool or pressurize the cabin. Instead, the current engine layout is all-electric bleedless, using an electrical compression and cooling system to maintain the cabin climate and power deicing systems. This allows for the simplification of internal arrangements through the elimination of the complex duct and valve work needed to regulate and control the flow of bleed air throughout the aircraft. The two engines are attached to a common mounting system allowing for easier swapping of engines between manufacturers, although this procedure is rarely performed as most airlines operate engines from only a single manufacturer. Noise reduction features were added to the engines, including the use of sawtooth engine nacelles and redesigned zero-splice air inlets.

As part of the effort to reduce airport noise levels and improve fuel efficiency, the Electric Self-Taxi System was introduced, to allow the aircraft to taxi itself to the runway without assistance and without the use of the main engines. The system uses a series of electric motors to power three of the six wheels on each primary landing gear strut controlled by a separate throttle in the cockpit, allowing the aircraft to maneuver under APU power alone. This system is particularly useful when operating from remote runways, busy airports with long queues, or for shorter flights with greater proportionate fuel consumption on the ground. With the increases in fuel efficiency as well as the elimination of the engine bleed systems, maximum range is improved over existing aircraft while noise levels both internally and externally are reduced.

A North Iberian AFGT-3000 APU is located in the fuselage tail cone, providing power to start the main engines and power the wheel hub motors if installed. Like the main engines, the APU is also bleedless, supplying electrical power to run onboard systems. As a result of increased demand and the all-electric design, the APU has an electrical capacity three times greater than previous aircraft. A ram-air starter located in the wing root provides emergency starting capability, although the APU is normally started via the onboard battery system. Initial design studies considered the possibility of a fuel cell or hybrid fuel cell APU, which was deemed immature for use at launch although tests continue on SOFC, SOFC-GT, and PEMFC alternatives.

Cabin

The fuselage cross-section is circular with a 6.3 m (20.7 ft) exterior diameter and a 6.05 meter internal diameter, sufficient to accommodate a 9-abreast premium economy or 10-abreast conventional economy seating arrangement. The 9-abreast seating option allows for 48 cm (19 in) seat widths, while the 10-abreast configuration allows for 45 cm (17.7 in) seat widths, improving passenger comfort. The use of stronger composite materials with greater resistance to moisture allows cabin pressure to be increased to a 1,800 m (6,000 ft) equivalent from the conventional 2,400 m (8,000 ft) equivalent and humidity raised to 18%.

Flexible illumination is provided by the all-LED lighting system, with computerized controls allowing full customization of lighting colors and profiles. The large 28 by 48 cm (11 x 19 in) windows provide better views and are located closer to eye level for easier viewing by passengers. While electrochromic smart glass is used for window construction, manual shades may be installed if requested by clients. The smart glass system allows flight attendants to remotely control the window opacity if desired, darkening or brightening the cabin on command. The integrated data and power network allows for the easier installation of in-flight entertainment options including seatback screens with video on demand service and electrical outlets for personal electronics.

Flight crew rest areas are provided at the front of the cabin just aft of the cockpit, and are designed to minimize intrusion into the passenger cabin. Cabin crew rest areas are provided at the rear of the cabin in the aft galley and both rest areas provide full-height standing space for crew to dress and undress, as well as lavatory facilities.

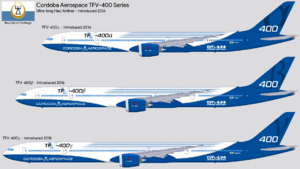

Variants

Fuselage length and range are the primary differentiating features between variants. The initial launch of the TFV-400 included two variants aimed at different market segments, plus private and government types. As with previous models, TFV-400 variants are identified by Greek letters, although due to keyboard restrictions Latin characters are often substituted instead.

TFV-400α

The baseline version, entering service with Phoenician Airways in September 2013. The 400α has a range of 17,590 km (9,500 nmi) and a maximum seating capacity of 520 passengers in a single-class economy configuration with ten-abreast seating. It is aimed primarily at the conventional long-haul transoceanic routes to replace older, less efficient twinjets and quadjets, and to expand into the ultra-long-haul market. The range allows for higher capacity Carthage-Edo flights via Russian or Inuk territory, increasing flexibility in the event of political trouble. 860 aircraft have been ordered, and as of January 2017, 344 have been delivered and are in service.

TFV-400β

The TFV-400β incorporates a fuselage stretch to 76.5 m (250 ft), allowing for up to 570 passengers to be seated in a single-class economy configuration. The type is rated for engines up to 500 kN (112,000 lbf) and has a higher gross takeoff weight, but due to greater passenger and fuselage weight, expected range is reduced to 15,200 km (8,200 nmi). With greater passenger density, the type is designed to be used on highly-trafficked domestic and international routes, including the popular Carthage-Havana and Carthage-Lagos pairs. 672 aircraft have been ordered, with 101 aircraft delivered to date.

Government and corporate

The TFV-400 airframe is available to private and public customers, and has been acquired or considered for a number of acquisition programs.

- TFV-400 Business Jet: The TFV-400 is marketed toward corporations and wealthy individuals via the Cordoba Private Aircraft business unit. Both airframe types are offered, although furnishings are the responsibility of a third-party contractor of the client's choice. Currently twelve units have been purchased, all of the 400α design.

- RTP-230 Skyliner: The RTP-230 is the VIP transport variant operated by the 142nd Airlift Wing of the Carthage Air Forces. Twenty four aircraft were ordered with four delivered. The RTP-230 incorporates additional fuel tanks and security features to improve range and protection, as well as additional secure communications equipment. Four aircraft are at the disposal of the suffetes for official travel purposes, with the remaining aircraft operated for use by other government and military officials, including diplomatic envoys in support of Carthage's foreign commitments. The type is expected to replace the previous inventory of TFV-340NG variants.

- RFS-230 Pelican: The RFS-230 is a proposed multi-role tanker-transport conversion of the 400α airframe. After consideration by the Air Forces, it was decided not to proceed with the proposal due to the number of RFS-224A Albatross MRTTs already in service.

- RES-282 Shogun: The RES-282 is a multi-role support aircraft designed to house a wide variety of sensors and communications equipment. Depending on equipment outfit, the RES-282 can serve as a AEW&C platform for air operations, a SIGINT platform for eavesdropping and electronic monitoring, an electronic attack platform, and a ground surveillance platform. It is designed to replace the RES-280 Ninja and RES-281 Daimyo in these roles.

Specifications

| Model | TFV-400α | TFV-400β | RTP-230 Skyliner |

|---|---|---|---|

| Cockpit crew | Two | ||

| Seating, typical | 354 (3-class) 420 (2-class) 520 (maximum) |

400 (3-class) 470 (2-class) 570 (maximum) |

N/A |

| Length | 69.4 m (228 ft) | 76.5 m (251 ft) | 69.4 m (228 ft) |

| Wingspan | 72 m (236 ft) unfolded 65 m (213 ft) folded | ||

| Wing sweepback | 32.2 degrees | ||

| Height | 19.6 m (64 ft) | ||

| Cabin width | 6.05 m (19.8 ft) | ||

| Seat width | 48 cm (19 in) in nine-abreast economy 45 cm (18 in) in ten-abreast economy |

N/A | |

| Cargo capacity | 178 m3 (6,280 cu ft) 40 x LD3 |

225 m3 (7,945 cu ft) 48 x LD3 |

N/A |

| Maximum takeoff weight | 350,000 kg (770,000 lb) | 381,000 kg (840,000 lb) | |

| Maximum landing weight | 254,000 kg (560,000 lb) | 260,000 kg (570,000 lb) | |

| Maximum zero-fuel weight | 241,000 kg (531,000 lb) | 244,000 kg (538,000 lb) | 250,000 kg (550,000 lb) |

| Operating empty weight | 152,000 kg (335,000 lb) | 188,000 kg (414,000 lb) | 196,000 kg (432,000 lb) |

| Cruising speed | Mach 0.85 (913 km/h, 567 mph, 490 knots, at 10,700 m (35,100 ft)) | ||

| Maximum speed | Mach 0.90 (954 km/h, 593 mph, 515 knots, at 10,700 m (35,100 ft)) | ||

| Range, fully loaded | 17,590 km (9,500 nmi) | 15,200 km (8,200 nmi) | 16,500 km (8,900 nmi) |

| Takeoff distance at MTOW (sea level, ISA) |

2,850 m (9,350 ft) | 3,050 m (10,010 ft) | 2,600 m (8,500 ft) |

| Maximum fuel capacity | 182,000 l (48,000 US gal) | ||

| Service ceiling | 13,200 m (43,300 ft) | ||

| Engines (×2) | Cordoba Turbomechanics GTxa-400-470B Elissa-Arishat ANF-390-465A General Electric GE90-110B4 |

Cordoba Turbomechanics GTxa-400-515A Elissa-Arishat ANF-390-515B General Electric GE90-115B4 |

Cordoba Turbomechanics GTxa-400-515A Yatagarasu Turbo-engineering SX-515M |

| Thrust (×2) | 470 kN (110,000 lbf) | 515 kN (116,000 lbf) | |