D-PAT

| D-PAT | |

|---|---|

| |

| Type | Anti-tank rocket launcher |

| Place of origin | Astronea |

| Service history | |

| In service | 1968-present |

| Used by | Astronean Armed Forces |

| Production history | |

| Designer | Arlogh Ballistics |

| Designed | 1967 |

| Manufacturer | ACC Defence Division |

| Unit cost | $700 |

| Produced | 1968-present |

| Specifications | |

| Length | 123 mm (4.8 in) |

| Barrel length | 123 mm (4.8 in) |

| Caliber | 64mm Shell HEAT warhead |

| Muzzle velocity | 115 m/s (380 ft/s) |

| Effective firing range | 200 m (220 yd) |

| Maximum firing range | 600 m (660 yd) |

| Sights | Flip-up iron sights |

| References | |

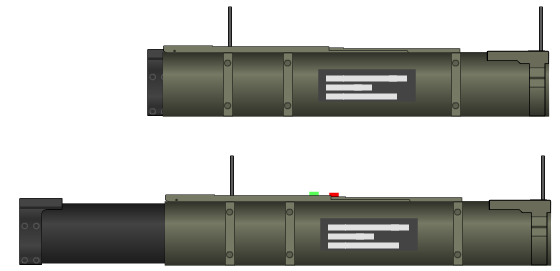

Designed in 1967, D-PAT stands for Disposable-Portable Anti Tank. The D-PAT's design was intended to be as compact and cost effective as possible. A simple two-part tubular launcher with a single unguided rocket mounts a 64mm warhead. The tube of the weapon folds out when armed, and is folded into one part when being transported. This allows for mobility and ease of transportation for operators carrying the launcher.

Sights are simple flip up front and rear leaf sights with sighting out to 200 m. The warhead is able to demolish structures such as walls and small buildings, as well as disable and destroy light armoured vehicles. The D-PAT comes with a sling for which is worn over the shoulder for carrying.

The D-PAT has been in service with Astronean forces since its inception, and due to its incredibly light weight, is issued to grenadiers of every fir eteam and squad to improve anti vehicle capabilities without significantly impacting the weight of the unit's overall gear. Firing the weapon is simple. The rear safety clip of the launcher's tube contains a pin, lever and push button.

By disengaging the level, removing the pin and pushing the button, the rear spring of the inner tube is released on a slide, allowing it to be pulled back. Once the tube has fully extended, a click will be heard, indicating that the warhead is ready to be fired. At this point, the launcher can be disarmed and refolded simply by reversing the arming steps. Once the weapon is shoulder, the operator holds down the green safety button on top of the frame with one finger, then while still holding the green button, presses the red button down in order to fire the rocket. The launcher is single use and once fired, the tube may be disposed of.

Design

The D-PAT consists of two tubes with a single 64mm unguided rocket inside.

The outer tube contains the trigger, the arming handle, front and rear sights, and the rear cover. The inner tube contains the channel assembly, which houses the firing pin assembly, including the detent lever. When extended, the inner tube telescopes outward toward the rear, guided by the channel assembly, which rides in an alignment slot in the outer tube's trigger housing assembly. This causes the detent lever to move under the trigger assembly in the outer tube, both locking the inner tube in the extended position and cocking the weapon. Once armed, the weapon is no longer watertight, even if the launcher is collapsed into its original configuration.

When fired, the striker in the rear tube impacts a primer, which ignites a small amount of powder that "flashes" down a tube to the rear of the rocket and ignites the propellant in the rocket motor. The rocket motor burns completely before leaving the mouth of the launcher, producing gases around 1,400 °F (760 °C). The rocket propels the 64-mm warhead forward without significant recoil. As the warhead emerges from the launcher, six fins spring out from the base of the rocket tube, stabilizing the warhead's flight. The early D-PAT warhead uses a simple, but extremely safe and reliable, piezoelectric fuze system. On impact with the target, the front of the nose section is crushed causing a microsecond electric current to be generated, which detonates a booster charge located in the base of the warhead, which sets off the main warhead charge. The force of the main charge forces the copper liner into a directional particle jet that, in relation to the size of the warhead, is capable of a massive amount of penetration.

A unique mechanical set-back safety on the base of the detonator grounds the circuit until the missile has accelerated out of the tube. The acceleration causes the three disks in the safety mechanism to rotate 90° in succession, ungrounding the circuit; the circuit from the nose to the base of the detonator is then completed when the piezoelectric crystal is crushed on impact.