JCh-6: Difference between revisions

No edit summary |

No edit summary |

||

| Line 131: | Line 131: | ||

Gun elevation ranges from -7.19 degrees to +14.55 degrees, giving the JCh-6 marginally better hull-down capability than the JCh-5 and T-74 but still less depression than many Western MBTs. With the stabilizer activated, gun elevation is limited to -6.28 to +13.72 degrees. This ensures that the gun does not abruptly ram into its hard upper or lower stops during movement over rough terrain. The JCh-6 has a full degree of additional depression compared to the JCh-5 and T-74, but its depression is still substantially behind that of many Western MBTs, limiting its ability to fight from a {{wp|Hull-down#Armoured_warfare|hull-down position}}. The gun's maximum elevation is also relatively poor, because the gun's recoil guard collides with the raised floor of the autoloader. This limits the JCh-6's ability to fight in hilly, mountainous, or urban terrain, but also reduces its overall profile, making it more effective in open terrain. | Gun elevation ranges from -7.19 degrees to +14.55 degrees, giving the JCh-6 marginally better hull-down capability than the JCh-5 and T-74 but still less depression than many Western MBTs. With the stabilizer activated, gun elevation is limited to -6.28 to +13.72 degrees. This ensures that the gun does not abruptly ram into its hard upper or lower stops during movement over rough terrain. The JCh-6 has a full degree of additional depression compared to the JCh-5 and T-74, but its depression is still substantially behind that of many Western MBTs, limiting its ability to fight from a {{wp|Hull-down#Armoured_warfare|hull-down position}}. The gun's maximum elevation is also relatively poor, because the gun's recoil guard collides with the raised floor of the autoloader. This limits the JCh-6's ability to fight in hilly, mountainous, or urban terrain, but also reduces its overall profile, making it more effective in open terrain. | ||

=== | ===Autoloaders=== | ||

The most distinctive feature of the JCh-6 is its dual-autoloader arrangement. This was primarily a result of the 1990s MoND requirement that the tank be able to fire unitary 125mm APFSDS ammunition without seriously sacrificing ammunition capacity, and it steadily evolved through Chikai's S.804, S.806, and S.806G prototypes. | The most distinctive feature of the JCh-6 is its dual-autoloader arrangement. This was primarily a result of the 1990s MoND requirement that the tank be able to fire unitary 125mm APFSDS ammunition without seriously sacrificing ammunition capacity, and it steadily evolved through Chikai's S.804, S.806, and S.806G prototypes. | ||

| Line 138: | Line 138: | ||

The carousel autoloader is located at the bottom of the turret basket and carries 22 two-piece rounds with the charges stacked horizontally over the projectiles and the front ends of the projectiles facing the hub of the autoloader. The central hub contains the carousel rotation motor as well as the power and communication connections between the turret and the hull. In principle, the JCh-6 carousel is very similar to the T-74 carousel: it rotates independently of the turret to select the desired ammunition type, at which point the desired ammunition is hoisted up behind the gun breech at a fixed elevation of +5.9 degrees and a two-stroke ramming process loads the projectile, then the charge. The actual lifting and ramming mechanism, however, is completely unlike the type used on the T-74, with the ramming chain wrapping horizontally around the turret ring instead of coiling vertically in the rear of the turret. The gun also loads at a higher angle. These changes ensure that the lifting and ramming equipment for the carousel autoloader do not obstruct the path of travel for rounds from the bustle autoloader. If the gun is already close to 5.9 degrees in elevation and the next ammunition type is pre-indexed before firing, the full loading cycle takes 8 seconds, increasing to 10 seconds if the gun is at maximum elevation or depression at the start of the loading process. This equates to 6-8 rounds per minute when using the carousel autoloader. | The carousel autoloader is located at the bottom of the turret basket and carries 22 two-piece rounds with the charges stacked horizontally over the projectiles and the front ends of the projectiles facing the hub of the autoloader. The central hub contains the carousel rotation motor as well as the power and communication connections between the turret and the hull. In principle, the JCh-6 carousel is very similar to the T-74 carousel: it rotates independently of the turret to select the desired ammunition type, at which point the desired ammunition is hoisted up behind the gun breech at a fixed elevation of +5.9 degrees and a two-stroke ramming process loads the projectile, then the charge. The actual lifting and ramming mechanism, however, is completely unlike the type used on the T-74, with the ramming chain wrapping horizontally around the turret ring instead of coiling vertically in the rear of the turret. The gun also loads at a higher angle. These changes ensure that the lifting and ramming equipment for the carousel autoloader do not obstruct the path of travel for rounds from the bustle autoloader. If the gun is already close to 5.9 degrees in elevation and the next ammunition type is pre-indexed before firing, the full loading cycle takes 8 seconds, increasing to 10 seconds if the gun is at maximum elevation or depression at the start of the loading process. This equates to 6-8 rounds per minute when using the carousel autoloader. | ||

Both the bustle autoloader and the carousel autoloader are powered by the tank's hydraulic | Both the bustle autoloader and the carousel autoloader are powered by the tank's hydraulic system. The hydraulic motor for the bustle autoloader is located in the turret bustle, and has a small blowoff plate of its own. The hydraulic motor for the carousel autoloader is located on the floor of the hull. Both autoloaders have manual hand crank controls in the event that the hydraulics fail: the carousel autoloader's hand cranks are on the side of the commander's position, and the bustle autoloader's hand cranks stick through the rear wall of the turret behind the commander's head. Manual cycling time depends on the condition of the crew. There is no procedure to manually reload the gun, but this is a negligible drawback, as there is also no loose ammunition stowage outside the autoloader. | ||

Menghean unitary and two-piece 125mm tank round casings are 90% combustible: only the steel base of the propellant section, which seals the breech during firing, remains in the chamber after firing. When the gun recoils, this spent casing stub is ejected into a metal arm behind the breech, which catches it and then ejects it through a spring-loaded hatch in the turret roof. This briefly compromises the tank's airtight seal, but the fighting compartment is pressurized to slightly over atmospheric pressure and the hatch is open for less than a second, so only a small amount of contaminated air can enter. This ejection system also reduces the buildup of fumes in the fighting compartment, as spent 125mm casing stubs often continue to smolder for several seconds after firing. | |||

Replenishing the bustle autoloader from a supply truck is relatively easy: the gunner manually rams new rounds through a hatch in the rear of the turret bustle, as the commander cycles the autoloader from inside the tank and records the round in each position. This is about as fast as replenishing rounds in a tank with a manual loader. Replenishing the carousel autoloader is more time-consuming: the driver and gunner pass ammunition through the commander's hatch to the commander, who loads the projectile and charge into a raised ammunition casette, then lowers the casette and advances the autoloader with a hand crank. Fully replenishing both autoloaders from an external supply vehicle or depot crate takes under 10 minutes in total. | |||

Because the two autoloaders function independently of one another, each one can still function if the other is damaged. Thus, while the probability of at least one autoloader failing is twice as high, the probability that both autoloaders fail independently is much lower. For example, if the bustle autoloader is penetrated and the ammunition inside cooks off through the blowoff panels, the crew can still perform a fighting retreat, using HE and HEAT ammunition from the carousel to suppress enemy threats. This compares favorably with some [[Letnia]]n split autoloader concepts in which the projectiles are stored on the turret floor and the charges are stored in the turret bustle; on these prototypes, a failure in either autoloader would disarm the tank. | |||

Redundancy is a beneficial side effect of the dual autoloader configuration, but not the main reason for its adoption. The system's main benefits are as follows. | |||

* The carousel autoloaders used on the JCh-5 and JCh-6 (lower hull) break down their rounds into two pieces, usually a charge and a complete projectile, for storage. This is not a problem for other ammunition types, but it imposes a strict upper limit on the length of APFSDS penetrators, which must fit in the projectile section of the carousel. The turret bustle, by contrast, can hold unitary 125mm rounds with very long penetrators. | |||

* Manual internal replenishment of the autoloader is time-consuming for two-piece 125mm ammunition, and impossible for unitary 125mm ammunition, which at over 1100 mm in overall length is far too cumbersome to move around inside the confines of the fighting compartment. On the JCh-6, all 36 rounds of main gun ammunition are in an autoloader of some kind, so there is no need to expand the fighting compartment or replenish unitary rounds externally. | |||

* Loose reserve ammunition stowage was also identified as the leading cause of catastrophic ammunition fires on the JCh-5 and other T-series tanks. With the bustle autoloader separated from the fighting compartment by a steel bulkhead, the carousel autoloader covered by a steel plate, and no loose ammunition anywhere else in the hull, the JCh-6 has a lower risk of ammunition cookoff than most other MBTs. | |||

* A full-width bustle autoloader would only hold 20-24 rounds, insufficient to meet the 36-round stowage requirement. | |||

* A full-width bustle autoloader would also have flat side armor, and would be vulnerable to enemy APFSDS fire if the turret is facing more than a few degrees away from the threat. Fully armoring the turret bustle with composite armor would add excessive weight. The JCh-6's tapering turret bustle is fully masked from view over the turret's 40-degree frontal arc, and too steeply angled for APFSDS projectiles to penetrate over the turret's 50-degree frontal arc. Even at the edges of the turret's 60-degree frontal arc, projectiles striking the front half of the bustle would have to pass through close to a meter of angled composite armor, and projectiles striking the rear half would exit the rear of the bustle without impacting the ammunition. | |||

There are nevertheless some drawbacks of the two-autoloader layout. First, both the added autoloader machinery and the turret bustle armor add to the tank's weight, bringing the fighting mass close to 50 metric tonnes. Second, while the carousel ammunition is relatively well-protected against spall damage, an {{wp|Improvised explosive device|IED}} blast or projectile impact on the lower hull can still set off a catastrophic ammunition fire. Third, the spent casing ejection hatch briefly compromises the tank's CBRN protection system. Fourth, the crew does not have a wide choice of ammunition loadouts. The tank can only carry up to 14 full-length APFSDS rounds, and it can carry no more than 22 HE, HEAT, canister, and beam-riding ATGM rounds in total. Finally, while the tapered turret bustle is mostly hidden from view or well-angled over the 60-degree frontal arc, it can easily be penetrated by tank ammunition, ATGMs, and RPG fire from the sides and rear. These flaws, however, are no less severe on the Leclerc and Challenger 2, and in some respects more serious on those tanks. | |||

===Other armament=== | ===Other armament=== | ||

Revision as of 19:35, 28 August 2021

This article is incomplete because it is pending further input from participants, or it is a work-in-progress by one author. Please comment on this article's talk page to share your input, comments and questions. Note: To contribute to this article, you may need to seek help from the author(s) of this page. |

| JCh-6 | |

|---|---|

The three JCh-6 service variants using the "G turret," plus the Sije-Chalyang 808 prototype. | |

| Type | main battle tank |

| Place of origin | |

| Service history | |

| In service | 2004-present |

| Used by | |

| Wars | Ummayan Civil War Innominadan Crisis |

| Production history | |

| Designer | Design Bureau of the Jinjŏng Chŏlgang-Nodongja Vehicle Plant |

| Designed | 1992-2002 |

| Produced | 2003-present |

| No. built | at least 16,000 |

| Variants | JCh-6G, JCh-6N, JCh-6D, JCh-6R, JCh-6M, JCh-5/6 |

| Specifications (JCh-6G) | |

| Weight | 50.2 metric tonnes |

| Length | 9.68 m overall 7.23 m hull only |

| Width | 3.77 m including side armor |

| Height | 2.27 m to turret roof |

| Crew | 3 (driver, gunner, commander) |

| Armor | welded steel base Composite armor (turret face and hull glacis) |

Main armament | 125mm L/48 smoothbore gun |

Secondary armament | 12.7mm GCh-75Ch HMG (commander) 7.62mm GCh-77 MMG (co-axial) |

| Engine | Taekchŏn D130 diesel 858 kW (1,150 hp) |

| Power/weight | 22.9 hp/tonne |

| Suspension | torsion-bar |

| Ground clearance | 43 cm |

Operational range | 800 km (internal fuel) |

| Speed | 65 km/h (road) |

The JCh-6 (formal designation: 6호 주력 전차 / 六號主力戰車, Ryuk-ho Juryŏk Jŏncha, "No.6 Main Battle Tank;" short designation: 전차-6 Jŏncha-ryuk) is a main battle tank designed and built in Menghe. Mass production began in 2003, with service deliveries early the following year. It is sometimes accompanied by the nickname Sŏnbong (선봉 / 先鋒), meaning "Vanguard," though this is more of a marketing device than an actual designation. The JCh-6 is currently the second most common main battle tank among the Menghean Army's active forces, though the JCh-5 outnumbers it in the reserves and the JCh-8 has begun replacing it in some front-line units.

Compared to the JCh-5 before it, the JCh-6 incorporates a number of new features, most notably a dual autoloader which allows the vehicle to store a large number of one-piece and two-piece 125mm rounds. This came at the cost of greater mechanical complexity, resulting in reliability problems on early models, but it enabled the JCh-6 to achieve much higher armor penetration than 125mm-armed tanks with carousel autoloaders. It also influenced the JCh-6's distinct appearance, with a tapering turret bustle and a low hull profile.

Development

Although the JCh-5 MBT had been considered fairly advanced during its early years in service, by the early 1990s concerns about its inadequacy were growing. Menghean policymakers closely followed the 1991 invasion of Kouraki, in which Anglian Challenger 1 and Dayashinese Type 90 tanks easily defeated Kouraki's core force of T-74 tanks. Though Menghe did not operate the T-74, its JCh-5 had the same main gun and fired similar ammunition. Menghean designers were especially concerned by reports that T-74s were unable to defeat the composite turret armor of the Challenger 1 and Type 90, even at the shortest of ranges.

Menghe had developed new ammunition types for the JCh-5 in the 1980s, but such incremental changes had limited potential. The JCh-5's carousel autoloader, which split ammunition into two pieces for storage, imposed a hard upper limit on the length of APFSDS projectiles. This, in turn, limited the main gun's armor penetration capability. The Chikai Heavy Machine Building Plant began work on a revised carousel design with a smaller central hub, allowing slightly longer APFSDS ammunition, but the designers saw this as little more than an interim solution.

The first records of a larger solution date from 1993, when the design bureau of the Chikai Heavy Machine Building Plant drew up blueprints for a prototype vehicle designated S.804. The new tank would be largely identical to the JCh-5, but would feature a modified turret with a box protruding from the rear. This box would house an autoloader with twelve unitary 125mm rounds. The 28-round autoloader within the hull would remain in place as well, albeit with a slightly modified ramming drive to keep the bustle autoloader's reloading path clear. According to design notes, the bustle would be loaded exclusively with a new type of APFSDS ammunition featuring a longer penetrator. The hull autoloader would carry HE, HEAT, and ATGM ammunition, all of which can be broken down into two parts without meaningfully degrading performance.

A working prototype was produced in 1996, built out of a modified JCh-5D hull with the reactive armor removed and an autoloader module welded to the rear of the turret. At this point in time the unitary 125mm round was still in development, so the design team tested the loading process with dummy ammunition. No firing trials were conducted. A Ministry of National Defense procurement team traveled to the Ketchvan SAP to observe a mobility test and demonstration of the new tank, but they were unimpressed with its construction. The thinly armored autoloader box was a particular source of concern; it was built from thin armour steel, meaning that enemy 12.7mm fire from combat ranges would be able to damage or even detonate the stored ammunition. The S.804 prototype was placed in storage in 1998, though it would later see new life as the JCh-5.5.

During the same time frame, the Insŏng Tank Plant developed a competing prototype. This vehicle, designated S.807, was armed with a brand-new 127mm smoothbore gun firing a new type of unitary ammunition. The new calibre was chosen to avoid logistical confusion, as its ammunition was not reverse-compatible with other Menghean 125mm tank ammunition. A total of 22 rounds of main gun ammunition were stored in a bustle autoloader, with 20 more in the hull front alongside the driver. Because of the fighting compartment's small dimensions, the hull ammunition stowage could only be transferred to the autoloader externally, with the commander passing it to the gunner and the gunner loading it through the top of the turret bustle. The S.807 was a surprisingly modern design, resembling the Dayashinese Type 90 in overall layout, but this also made it more complex and expensive. Furthermore, Insŏng was less experienced than Chikai at tank design, having only opened in the 1980s as a secondary production site for the JCh-5. The first fully-functional S.807 prototype was only rolled out in 1999, by which point the S.806 prototype had emerged as a clear front-runner.

The S.806 was Chikai's answer to the MoND's critiques of the S.804 prototype. It used the same basic configuration as the S.804, with a linkless-belt-type autoloader in the turret bustle holding 12 unitary rounds (later increased to 16) and a carousel autoloader in the hull holding the remaining two-piece ammunition. The internal systems, however, were wrapped in an entirely new turret exterior, with autocannon-resistant armor plating entirely surrounding the bustle autoloader and blending smoothly into the rest of the turret. The hull was also slightly enlarged, and the slope of the upper glacis plate was increased. The roadwheels were greatly enlarged and given wear-resistant rubber surfaces to address problems with wheel and track life on the JCh-5. To compensate for the added weight of armor and machinery, a more powerful V-12 diesel engine was installed in the larger rear compartment, generating 1,100 hp.

The initial version of the S.806 prototype featured a "bowl-shaped" carousel autoloader nearly identical to the type used on the JCh-5, with the charges sitting upright in a ring around the fighting compartment. This was more familiar to Chikai's designers, and it allowed for a faster rate of fire than the two-stroke autoloader on the T-74. Analysis of combat losses in the Polvokian Civil War, however, revealed that a number of JCh-5 tanks suffered catastrophic burn-outs due to HEAT charges penetrating the upper hull sides and striking the upright charges. Concerned about survivability, the MoND instructed Chikai to develop an alternative carousel autoloader with a lower height profile and an armored roof. This proved to be a challenge, as Menghe did not have production rights to the Letnian T-74 and a copied version of its electric hoist and ramming system would obstruct the ramming path of unitary shells from the bustle autoloader. A modified prototype was finally rolled out in 2002, this time featuring a carousel autoloader similar in configuration to that of the T-74 but with a hydraulic lifting and ramming system incorporating elements of the JCh-5's autoloader design. This lowered the autoloader's profile within the hull and allowed the installation of an armor plate on top. This modified design received the prototype designation S.806G.

Satisfied with the last round of changes, the MoND approved the S.806G for mass-production in 2002, giving it the designation JCh-6. As the winner of the competition, the Chikai Heavy Machine Building Plant was awarded a contract for mass-production of the JCh-6, with Insŏng handling upgrades and refits of existing JCh-5 hulls.

Description

Layout

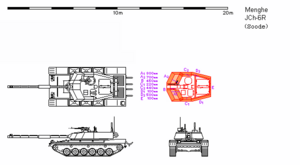

The JCh-6 has the same general layout as the JCh-5 before it, with the driver in the front of the hull, the gunner on the left side of the turret, the commander on the right side of the turret, and the engine and transmission in the rear. Its most distinctive visual feature is a long turret bustle which tapers inward at 20 degrees. This distinguishes it from the JCh-5, which has a circular (JCh-5G) or octagonal (JCh-5N/D/R) turret. The front half of the turret also tapers inward at 20 degrees before angling more sharply inward to form the turret face, distinguishing early JCh-6 tanks from later JCh-6 models and the JCh-8 and -10.

In terms of its overall size, the JCh-6 represents an incremental change in Menghean tank design doctrine. It is slightly larger in all dimensions than the JCh-5, measuring 2.38 meters to the turret roof, and consequently heavier, weighing 47 tonnes fully loaded without reactive armor. Yet it is still shorter and ligher than many Western MBTs, including the Ostish Leopard 2 and the Anglian Challenger 2. This puts it in roughly the same league as other foreign 3-crew tanks, such as the Sieuxerrian Leclerc tank and the Dayashinese Type 90. A more powerful engine compensates for the added mass, allowing the JCh-6 to match the JCh-5's speed and mobility, though its increased mass still impacts its airlifting ability and its bridging ability.

Despite the added armor and machinery, the JCh-6 is slightly more spacious than the JCh-5. The turret basket, which measures 1,940mm in diameter internally, is wider than the turret baskets on some 4-crew MBTs. The flat carousel autoloader gives more horizontal space to the commander and driver, as the turret basket is not ringed by ammunition. Moreover, all rotating parts of the carousel autoloader are contained below the turret floor, meaning that there is no risk of injury from body parts or clothing getting snagged during loading. The flat carousel autoloader also allows the crew to move between the driver's compartment and the turret compartment. On the JCh-5, this was only possible if one of the crew members removed three shell and propellant casettes from the autoloader to create an opening. The JCh-6 does offer its turret crew less vertical space than the JCh-5, as the turret floor is higher; but with no human loader competing for horizontal space, the gunner and commander can sit with their legs stretched forward.

Main armament

The main armament of the JCh-6 is the JChP-125 Type 01 125mm smoothbore tank gun. This is an offshoot of the 2A46 tank gun family used by the JCh-5 and other Letnian and Kolodorian tanks before it. Like other 2A46 derivatives, it has a barrel length of 6,000mm, a bore evacuator two thirds of the way along the barrel, and a horizontal sliding block breech. The recoil travel is 260 to 300 mm, with a hard stop at 310 mm. Like newer guns in the 2A46 family, the JChP-125 Type 01 has a thermal sleeve, a chromium-lined barrel, an autofrettaged barrel and chamber assembly, and a disassembly mechanism which allows the crew to replace the barrel at a depot without having to lift off the turret. Compared with earlier versions of the 2A26 and 2A46, these changes give the JCh-6 increased accuracy, a longer barrel life of 1200 rounds, and compatibility with high-energy APFSDS ammunition.

Gun elevation ranges from -7.19 degrees to +14.55 degrees, giving the JCh-6 marginally better hull-down capability than the JCh-5 and T-74 but still less depression than many Western MBTs. With the stabilizer activated, gun elevation is limited to -6.28 to +13.72 degrees. This ensures that the gun does not abruptly ram into its hard upper or lower stops during movement over rough terrain. The JCh-6 has a full degree of additional depression compared to the JCh-5 and T-74, but its depression is still substantially behind that of many Western MBTs, limiting its ability to fight from a hull-down position. The gun's maximum elevation is also relatively poor, because the gun's recoil guard collides with the raised floor of the autoloader. This limits the JCh-6's ability to fight in hilly, mountainous, or urban terrain, but also reduces its overall profile, making it more effective in open terrain.

Autoloaders

The most distinctive feature of the JCh-6 is its dual-autoloader arrangement. This was primarily a result of the 1990s MoND requirement that the tank be able to fire unitary 125mm APFSDS ammunition without seriously sacrificing ammunition capacity, and it steadily evolved through Chikai's S.804, S.806, and S.806G prototypes.

The bustle autoloader in the rear of the turret carries 14 unitary rounds in a linkless belt configuration, with the rounds running in a sideways 0 shape around a central belt assembly which cycles them using metal paddles which extend into the spaces between the rounds. This is similar in concept to the bustle autoloaders on the T-10, Type 90, and Leclerc MBTs. The center position in the bottom row has a hydraulically powered semi-rigid chain which rams the selected projectile through a hole in the turret bustle bulkhead and into the breech of the gun. Loading takes place at a fixed elevation of -2.39 degrees, so the gun must depress to this angle as part of the reloading cycle and then return to its previous angle. This is just shy of the maximum allowable depression when the turret is facing to the rear and the gun is over the engine deck. The belt can cycle either clockwise or counterclockwise, and it automatically cycles in the direction with the closest round of the selected type. If the gun is already depressed at close to -2.39 degrees and the desired ammunition type is already indexed, the loading cycle takes slightly over 5 seconds. This equates to a rate of fire of 11 rounds per minute when using the bustle autoloader. At maximum gun elevation, the total loading process increases to just under 8 seconds, and it can increase further if the desired ammunition type is on the far side of the belt and not pre-indexed.

The carousel autoloader is located at the bottom of the turret basket and carries 22 two-piece rounds with the charges stacked horizontally over the projectiles and the front ends of the projectiles facing the hub of the autoloader. The central hub contains the carousel rotation motor as well as the power and communication connections between the turret and the hull. In principle, the JCh-6 carousel is very similar to the T-74 carousel: it rotates independently of the turret to select the desired ammunition type, at which point the desired ammunition is hoisted up behind the gun breech at a fixed elevation of +5.9 degrees and a two-stroke ramming process loads the projectile, then the charge. The actual lifting and ramming mechanism, however, is completely unlike the type used on the T-74, with the ramming chain wrapping horizontally around the turret ring instead of coiling vertically in the rear of the turret. The gun also loads at a higher angle. These changes ensure that the lifting and ramming equipment for the carousel autoloader do not obstruct the path of travel for rounds from the bustle autoloader. If the gun is already close to 5.9 degrees in elevation and the next ammunition type is pre-indexed before firing, the full loading cycle takes 8 seconds, increasing to 10 seconds if the gun is at maximum elevation or depression at the start of the loading process. This equates to 6-8 rounds per minute when using the carousel autoloader.

Both the bustle autoloader and the carousel autoloader are powered by the tank's hydraulic system. The hydraulic motor for the bustle autoloader is located in the turret bustle, and has a small blowoff plate of its own. The hydraulic motor for the carousel autoloader is located on the floor of the hull. Both autoloaders have manual hand crank controls in the event that the hydraulics fail: the carousel autoloader's hand cranks are on the side of the commander's position, and the bustle autoloader's hand cranks stick through the rear wall of the turret behind the commander's head. Manual cycling time depends on the condition of the crew. There is no procedure to manually reload the gun, but this is a negligible drawback, as there is also no loose ammunition stowage outside the autoloader.

Menghean unitary and two-piece 125mm tank round casings are 90% combustible: only the steel base of the propellant section, which seals the breech during firing, remains in the chamber after firing. When the gun recoils, this spent casing stub is ejected into a metal arm behind the breech, which catches it and then ejects it through a spring-loaded hatch in the turret roof. This briefly compromises the tank's airtight seal, but the fighting compartment is pressurized to slightly over atmospheric pressure and the hatch is open for less than a second, so only a small amount of contaminated air can enter. This ejection system also reduces the buildup of fumes in the fighting compartment, as spent 125mm casing stubs often continue to smolder for several seconds after firing.

Replenishing the bustle autoloader from a supply truck is relatively easy: the gunner manually rams new rounds through a hatch in the rear of the turret bustle, as the commander cycles the autoloader from inside the tank and records the round in each position. This is about as fast as replenishing rounds in a tank with a manual loader. Replenishing the carousel autoloader is more time-consuming: the driver and gunner pass ammunition through the commander's hatch to the commander, who loads the projectile and charge into a raised ammunition casette, then lowers the casette and advances the autoloader with a hand crank. Fully replenishing both autoloaders from an external supply vehicle or depot crate takes under 10 minutes in total.

Because the two autoloaders function independently of one another, each one can still function if the other is damaged. Thus, while the probability of at least one autoloader failing is twice as high, the probability that both autoloaders fail independently is much lower. For example, if the bustle autoloader is penetrated and the ammunition inside cooks off through the blowoff panels, the crew can still perform a fighting retreat, using HE and HEAT ammunition from the carousel to suppress enemy threats. This compares favorably with some Letnian split autoloader concepts in which the projectiles are stored on the turret floor and the charges are stored in the turret bustle; on these prototypes, a failure in either autoloader would disarm the tank.

Redundancy is a beneficial side effect of the dual autoloader configuration, but not the main reason for its adoption. The system's main benefits are as follows.

- The carousel autoloaders used on the JCh-5 and JCh-6 (lower hull) break down their rounds into two pieces, usually a charge and a complete projectile, for storage. This is not a problem for other ammunition types, but it imposes a strict upper limit on the length of APFSDS penetrators, which must fit in the projectile section of the carousel. The turret bustle, by contrast, can hold unitary 125mm rounds with very long penetrators.

- Manual internal replenishment of the autoloader is time-consuming for two-piece 125mm ammunition, and impossible for unitary 125mm ammunition, which at over 1100 mm in overall length is far too cumbersome to move around inside the confines of the fighting compartment. On the JCh-6, all 36 rounds of main gun ammunition are in an autoloader of some kind, so there is no need to expand the fighting compartment or replenish unitary rounds externally.

- Loose reserve ammunition stowage was also identified as the leading cause of catastrophic ammunition fires on the JCh-5 and other T-series tanks. With the bustle autoloader separated from the fighting compartment by a steel bulkhead, the carousel autoloader covered by a steel plate, and no loose ammunition anywhere else in the hull, the JCh-6 has a lower risk of ammunition cookoff than most other MBTs.

- A full-width bustle autoloader would only hold 20-24 rounds, insufficient to meet the 36-round stowage requirement.

- A full-width bustle autoloader would also have flat side armor, and would be vulnerable to enemy APFSDS fire if the turret is facing more than a few degrees away from the threat. Fully armoring the turret bustle with composite armor would add excessive weight. The JCh-6's tapering turret bustle is fully masked from view over the turret's 40-degree frontal arc, and too steeply angled for APFSDS projectiles to penetrate over the turret's 50-degree frontal arc. Even at the edges of the turret's 60-degree frontal arc, projectiles striking the front half of the bustle would have to pass through close to a meter of angled composite armor, and projectiles striking the rear half would exit the rear of the bustle without impacting the ammunition.

There are nevertheless some drawbacks of the two-autoloader layout. First, both the added autoloader machinery and the turret bustle armor add to the tank's weight, bringing the fighting mass close to 50 metric tonnes. Second, while the carousel ammunition is relatively well-protected against spall damage, an IED blast or projectile impact on the lower hull can still set off a catastrophic ammunition fire. Third, the spent casing ejection hatch briefly compromises the tank's CBRN protection system. Fourth, the crew does not have a wide choice of ammunition loadouts. The tank can only carry up to 14 full-length APFSDS rounds, and it can carry no more than 22 HE, HEAT, canister, and beam-riding ATGM rounds in total. Finally, while the tapered turret bustle is mostly hidden from view or well-angled over the 60-degree frontal arc, it can easily be penetrated by tank ammunition, ATGMs, and RPG fire from the sides and rear. These flaws, however, are no less severe on the Leclerc and Challenger 2, and in some respects more serious on those tanks.

Other armament

Protection

Mobility

Design (JCh-6G)

This article is incomplete because it is pending further input from participants, or it is a work-in-progress by one author. Please comment on this article's talk page to share your input, comments and questions. Note: To contribute to this article, you may need to seek help from the author(s) of this page. |

Protection

During its development, the JCh-6G was designed to resist contemporary 120mm APFSDS ammunition across the frontal arc without the use of explosive reactive armor, which could endanger nearby infantry and would leave openings in the tank's protection after being struck. For this purpose, it relied on a base layer and outer shell made of hardened steel, with composite armor of an unknown composition sandwiched in between. Areas with composite armor include the turret face and turret sides, as well as the hull glacis plate, though the latter relies primarily on sloping.

The tank's sides and rear are protected by hardened steel armor in various thicknesses. It is reportedly resistant to 30mm APFSDS ammunition from all angles at ranges above 1 kilometer, as well as shrapnel from nearby shell impacts. The hull sides use applique armor skirts, variously described as spaced or composite armor, which are designed to induce yaw in APFSDS ammunition approaching at an angle and prematurely detonate HEAT charges.

A unique distinguishing feature of the JCh-6 is the shape of its turret bustle, which grows narrower toward the rear, at an angle of about 12.5 degrees from the horizontal. This was intended to reduce the likelihood of an enemy projectile striking the stowed ammunition. Over the 30-degree frontal arc, the bustle itself is either not visible, or is visible at such a narrow angle that HEAT warheads would fail to detonate and APFSDS rounds would deflect off of the surface. The tank's designers predicted from exercises that in a conventional engagement in open terrain most incoming fire would come over the 60-degree frontal arc, and that the dispersion could be narrowed even further if crews rotated the turret to face a threat. If struck at a wider angle, however, the turret bustle would be protected by nothing more than 60 millimeters of hardened steel.

The autoloader is separated from the rest of the turret by a 12-centimeter-thick steel bulkhead, and an armored cover passes over the ramming hole when rounds are not being loaded. In the event that an enemy round penetrates the turret bustle, this bulkhead is meant to prevent the internal cookoff from injuring the crew or damaging other internal systems; the resulting pressure is instead vented upward through a large blowoff panel. The turret bustle also contains the hydraulic pumps for traversing the turret and elevating the guns; testing with the JCh-5 found that if these systems burst, they could project heated, flammable fluid into the tank, injuring the crew.

For protection against guided munitions, the JCh-6G carries smoke grenade projectors capable of quickly laying a multi-spectral smokescreen in front of the tank's turret. This system can be used to disrupt the guidance systems on certain anti-tank guided missiles, or to break the launch platform's lock on the target, during which time the JCh-6 can either prepare to engage the launch platform or retreat to safety. As the smoke grenades are activated manually by the commander upon spotting the incoming missile, it is debatable whether this constitutes a softkill active protection system, though it has some functional similarities. All JCh-6 variants can also inject diesel fuel into the engine exhaust, generating a thick smokescreen behind the tank in order to cover mechanized units advancing behind it or conceal its retreat.

In the event that the battlefield is contaminated by chemical, biological, radioactive, or nuclear weapons, the tank can be sealed against its environment, with an air filtration system ensuring an adequate supply of oxygen. While the main gun's breech is open, a combination of airflow from the bore evacuator and overpressure from the air filter prevent contaminants from entering via the gun barrel. The airtight seal is also breached for roughly one second during the firing cycle, as a panel above the breech opens to eject the spent stub at the end of the round's combustible casing. Overpressure can partially prevent the inflow of foreign air, but testing with the JCh-6 found that trace amounts of contaminated air could still enter the tank during this period, and the feature was eliminated on the JCh-8.

In spite of high hopes for the vehicle's design, combat experience in Ummayah revealed that modern armor-piercing ammunition could still penetrate the JCh-6 with relative ease across the 60-degree frontal arc. This led to new overhauls of the tank's protection in each subsequent variant.

Main Armament

Autoloader

The JCh-6 uses a conventional cycling belt autoloader in the turret bustle, as opposed to the carousel autoloader in the JCh-5. In order to load a new round, the belt cycles to the selected ammunition type, then rams it forward into the open breech of the gun, which is turned to an elevation of zero degrees horizontal in order to align with the incoming round. After each round is fired, a lever extracts the non-combustible stub at the end of the cartridge and ejects it from a hatch in the top of the turret, with air overpressure inside the tank preventing external contaminants from entering.

Under ideal circumstances, the firing cycle is as short as five seconds, but it can increase to six seconds or more if the gun is significantly out of alignment from zero degrees or if the next required round type is further down the cycling chain. Official Army sources list the maximum rate of fire as 10-12 rounds per minute. If the autoloader's cycling system is disabled, the turret crew can manually cycle the chain and ram rounds by means of hand cranks extending through the protective bulkhead. The firing cycle under these circumstances varies with the skill of the crew and the extent of the damage, but has been described as anywhere from fifteen to thirty seconds.

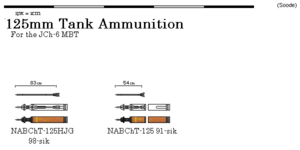

Ammunition

The crowning achievement of the JCh-6 main battle tank is the NABChT-125HJG, (abbr. 날개안정식 분리철갑탄, Nalgaeanjŏngsik Bunrichŏlgabtan, Fin-stabilized discarding-sabot armor-piercing round), an APFSDS-T anti-tank munition designed to take advantage of the full length of the cartridge rather than being limited to the first half like previous Menghean tank ammunition. The penetrator is 83 centimeters long, excluding the tracer, and 28 millimeters in diameter, and has a muzzle velocity of 1650 meters per second. At a range of 2,000 meters, it is reportedly able to penetrate 850 millimeters RHA equivalent, though performance varies depending on the composite armor scheme it is facing.

Apart from this, the JCh-6 is capable of handling the same two-piece HE and HEAT ammunition used by the JCh-5, a feature intended to streamline logistics on the battlefield. The chain assembly holding the rounds, the semi-rigid ramming chain, and the folding tray behind the breach prevent the two halves from separating.

For engagements at longer ranges, the JCh-6G through 6D can fire the YDCh-19 beam-riding ATGM through the gun barrel. Unlike the YDCh-16 before it, this projectile can be loaded directly from the autoloader, without requiring a human loader to insert a third compressed-air stage. Because they are stored in assembled form, rather than in separated units, YDCh-19 rounds fired from the JCh-6's autoloader reportedly have a lower failure rate. Increasing accuracy of fire-control systems on the JCh-6D onward, however, rendered the guided missile redundant, and the "R" and "M" variants are not configured to fire it.

Apart from poor side protection, another disadvantage of the angled turret bustle is that it limits the amount of space available for ammunition. Only 18 main gun rounds can be carried in the tank's autoloader, compared to 22 on other tanks of similar size and configuration. This compares poorly with the 26 ready rounds in the JCh-5. To increase the overall ammunition load, twenty additional rounds are stored under the turret floor, beneath armored hatches that can be pulled away by the crew. Two-piece ammunition can be manually passed into the autoloader without unbuttoning the tank, but the larger one-piece APFSDS rounds must be lifted through one of the hatches and inserted through the autoloader's roof. In both cases, the floor storage is notoriously hard to access, requiring that the turret be rotated to different angles in order to access each compartment. Reloading of this kind would only be performed while the tank is out of battle.

Other armament

The commander of the JCh-6 is provided with a 12.7mm GCh-75Ch heavy machine gun. This weapon is mounted to a rotating ring around the cupola, and can be rotated through 360 degrees with relative ease. As on the JCh-4 and JCh-5, it can be either manually operated from an open hatch or remotely operated from inside the tank, though in the latter case its optics are greatly improved over earlier Menghean tanks, improving the weapon's accuracy and range in the buttoned-up mode. A total of 400 rounds for the GCh-75Ch are carried in four 100-round boxes, one on the gun mount and three more in an external storage bin.

The JCh-6's other secondary armament is a single GCh-77Ch medium machine gun mounted co-axially with the main gun, on the commander's side. This weapon fires through a slot cut in the armor, with a canvas covering to maintain a protective air seal. The weapon fires 7.62x51mm ammunition, fed from a bin at the commander's feet. The ready bin carries 500 rounds of 7.62x51mm ammunition, with an additional 4,000 rounds stored around the tank, some inside the fighting compartment and others in external stowage bins.

Mobility

The JCh-6G is driven by a single 10-cylinder, 1,150-horsepower D130 diesel engine manufactured by Taekchŏn Heavy Industries. This gives it a power-to-weight ratio of 22.9 horsepower per tonne. The engine and transmission can be removed as a single unit to facilitate maintenance and replacement. Top speed on roads is cited as 65 kilometers per hour, while top speed offroad is dictated by the terrain. The tank has an operational range of 800 kilometers when relying on internal fuel only, and was not initially designed to accept fuel drums, though these became optional on the "D" variant onward.

To reduce production costs, the JCh-6 uses torsion bar suspension, at a time when hydropneumatic suspension was already becoming common on contemporary main battle tanks. The six roadwheels on each side are offset slightly to allow each one's torsion bar to pass all the way through to the other side.

Like previous Menghean MBTs, the JCh-6 carries a snorkel on the turret rear. The crew can mount this on a matching port over the gunner's hatch and extend it to its full length, allowing the tank to ford water obstacles up to five meters deep while maintaining constant airflow to the crew compartment and engine. In this configuration, the tank is blind until it surfaces at the far side of the water obstacle.

Early variants

JCh-6N

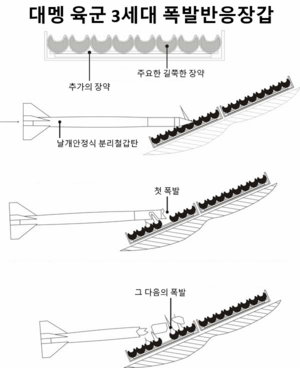

The JCh-6N was an interim response to the 6G's poor performance in the Ummayan Civil War. It added ERA plates to the turret face and glacis plate, with the goal of increasing protection against HEAT and APFSDS ammunition. The plates used are described in Menghean sources as "second-generation ERA," and feature multiple steel layers that expand apart on impact, inducing shear forces in APFSDS ammunition. These are believed to be the same armor plates used on the JCh-5R main battle tank.

JCh-6G tanks upgraded to "N" standard are formally designated JCh-6N1, but in practice JCh-6N applies to both, as the two are functionally identical.

JCh-6D

Introduced in 2008, the JCh-6D was a more substantial upgrade, and it is believed that work on the necessary changes was already underway when the -6N entered production. Its most visible feature was a different array of reactive armor plates, this time consisting of "third-generation ERA." This type uses linear shaped charges which detonate on impact and then spread up and down the plate, cutting apart projectiles and HEAT jets before they can strike the main armor. A secondary layer of conventional ERA underneath provides additional protection. This system is considered to be more effective against APFSDS ammunition than the ERA plates used on the JCh-5R, and is claimed to be effective against soft-tip and expanding-rod penetrators.

The JCh-6D also incorporates new fire-control systems, which were imported from Dayashina. The most visible of these is a much larger gunner's sight incorporating side-by-side visual-band and infrared-band cameras, as well as a more precise laser rangefinder. Combined with a new temperature and crosswind measurement mast, and a new firing computer, this upgrade greatly increases the gunner's likelihood of landing a first-round hit on a moving enemy vehicle at long ranges. Reportedly, the firing computer on the JCh-6D is capable of maintaining a "lock" on an enemy target, continuously updating the necessary lead as both tanks' velocity change. The "D" variant also brought the main armament stabilization system up to international standards, and added a laser reference module on top of the gun for easier calibration.

Additional protection on the JCh-6D comes in the form of an automated softkill active protection system. This consists of infrared sensors which are capable of detecting missile launches, and jamming devices designed to spoof, blind, or disrupt hostile missile guidance and laser rangefinder systems. The system is integrated with the tank's existing multi-spectral smoke grenade launchers, which are relocated to improve ERA protection, allowing the tank to automatically deploy defensive smokescreens at short notice. It also automatically reports the direction of the missile launch to the commander, who can then slew the turret to face the threat. Because wire-guided missiles can take seven seconds or more to travel 2,000 meters, this gives the gunner ample time to fire a main-gun round at the launch platform, breaking the lock for SACLOS, SALH, and beam-riding missiles.

Less visible was the addition of a new type of two-piece 125mm gun round. Designated "dual-purpose," this round's projectile incorporates a tandem HEAT warhead with a prefragmented outer casing around the main charge. It also has an airbursting fuse, which detonates the round near the target based on the distance calculated by the laser rangefinder and the time-of-flight predicted by the firing computer. This increases effectiveness against infantry in trenches or other open-topped covered positions, and allows the tank to more easily engage loitering or slow-moving helicopters. By combining high-explosive and light anti-armor capabilities, this also allows the tank to split its ready ammunition load between only two types of ammunition, APFSDS for heavy armor and dual-purpose for all other targets.

Another interesting feature of the JCh-6D was the reworking of the tank's communications suite. It was the first operational Menghean tank to carry the MChGJ-0800 C-band radio communications system. Limited to line-of-sight signals, but by the same virtue difficult to intercept and jam, the C-band antenna allows tanks within the same platoon or company to continue communicating even when lower frequencies are being targeted and jammed. For longer-ranged communications, the tank also carries UHF and VHF antennas. Apparently deemed a success in operational testing, the MChGJ-0800 was later carried over onto the JCh-6R and 6M, and to the JCh-5/6 and JCh-8.

A limited number of "G" and "N" variant tanks were upgraded to partial D standard, through the addition of third-generation ERA and the installation of updated optics. On close inspection, these can be distinguished from standard D-variant tanks by the welds and cuts around the gunner's optic and the mounting of the commander's optic on a more elevated mount. They also lack some components of the full fire-control system, including the automatic firing-solution update capability. These tanks are formally designated JCh-6D1.

JCh-6R

When unnamed photographs of the JCh-6R on trials were released to the public on May 4th, 2014, several foreign intelligence agencies provisionally designated it JCh-8, mistaking it for the new tank prototype rumored to be in development. In fact, it was a variant of the JCh-6 with a number of major modifications, including a new turret and applique frontal armor.

The JCh-6R pioneered several technologies that would later appear on the JCh-8 main battle tank, and in some respects served as a design testbed as well as a service vehicle. Indeed, it was a sufficiently revolutionary advance during its development that the Menghean Army nearly suspended work on the new tank project altogether. Its most recognizable improvement is a new turret, which maintains the same internal layout as the JCh-6G but uses a new external shape with thicker armor on all surfaces except directly to the rear.

Armament

Some early reports suggested that the JCh-6R was also designed to accept a 140mm gun, but this appears to have been false. It did, however, carry a revised variant of its predecessors' armament: the Jŏncha-Po 125/58, a 58-caliber artillery gun which was 1.25 meters longer than previous variants' JChP 125/48. It is also reportedly capable of handling new 125mm APFSDS ammunition, with stronger propellant optimized for the gun's longer length. Together, these modifications impart a considerably higher muzzle velocity to APFSDS projectiles, increasing penetration power.

Protection

The JCh-6R features a heavily revised turret face incorporating a new type of composite armor, which state sources claim is easier to manufacture but also more effective against APFSDS and HEAT ammunition. In contrast to previous variants, the turret's composite armor modules are mounted on top of an internal steel shell roughly 50 millimeters thick, and damaged modules can be replaced at a forward operating base with the assistance of a small crane. New "applique composite panels," possibly similar in structure to spaced armor, are also mounted on top of the hull glacis, to induce additional deflection in APFSDS rounds.

With the addition of these modules, the JCh-6R's conventional armor protection increased considerably by comparison with the JCh-6G, especially at the edges of the 60-degree frontal arc. According to the line-of-sight estimates in the image at right, the "R" turret's armor is 800 millimeters thick when viewed head-on, and the turret cheeks are nowhere thinner than 440 millimeters when viewed at a 60-degree angle. Because the armor uses composite plating, effective thickness may be even higher, depending on the threat; the "R" turret reportedly incorporates strike plates made of depleted uranium.

Mobility

As a result of these changes to its armor and armament, the JCh-6R also took on a great deal of additional weight, rising to over 57 metric tonnes. This required the addition of a new powerplant in order to maintain acceptable mobility. The designers responded by incorporating a 1500-horsepower diesel engine, bringing the power-to-weight ratio to 25.8 horsepower per tonne. This made the JCh-6R one of the more agile tanks in Menghe's arsenal at the time, with a top speed of 70 kilometers per hour on hard, level ground and good performance on slopes and obstacles.

The new engine required an expansion of the hull rear, which angles up to incorporate the larger powerplant and transmission. Exhaust is ducted through the left rear track cover and then vented upward, modestly reducing the tank's infrared signature in comparison with the side exhaust port on previous variants. To counteract the decreased fuel efficiency of the more powerful engine, the designers also restored the external fuel tank mounts.

To cope with the higher weight, the designers also added new, slightly stronger torsion bars. A mixed hydrobar suspension was considered, but eventually rejected as too radical for a variant in the same family.

JCh-6M

The JCh-6M, introduced in 2018, is a modest upgrade to the JCh-6R incorporating additional protective measures. The most notable change is the addition of "third-generation ERA" of the same type used on the JCh-6D on the turret face, and a Jŏgran-un active protection system. Third-generation ERA was also added to the hull glacis plate. These measures further improved the JCh-6R's survivability against long-rod 120mm and 125mm APFSDS, though they also increased weight and unit cost.

JCh-6R1

First seen in early 2019, the JCh-6R1 is a JCh-6R hull with third-generation ERA plates attached to the turret face and hull glacis plate. It lacks the JCh-6M's hardkill and softkill APS suite. It is apparently being prepared for export, as the Jŏgran-un suite is not authorized for shipment beyond Menghe, but could also be a low-cost interim upgrade for existing JCh-6R hulls. As of March 2019, no export deals involving the JCh-6R1 have been announced.