JCh-5.5: Difference between revisions

No edit summary |

No edit summary |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{infobox weapon | {{infobox weapon | ||

| name = JCh-5.5 | | name = JCh-5.5 | ||

| image = | | image = JCh-5.5_color_2022-06-08.png | ||

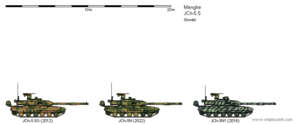

| caption = JCh-5. | | caption = The three major variants of the JCh-5.5 used in Menghe, as of 2022 | ||

| origin = [[Menghe]] | | origin = [[Menghe]] | ||

| type = {{wp|Main_battle_tank|Main battle tank}} | | type = {{wp|Main_battle_tank|Main battle tank}} | ||

| Line 21: | Line 21: | ||

<!-- Production history --> | <!-- Production history --> | ||

| designer = Chikai Tank Design Institute | | designer = Chikai Tank Design Institute | ||

| design_date = 1992- | | design_date = 1992-2012 | ||

| manufacturer = | | manufacturer = Insŏng Machine Building Plant | ||

| unit_cost = | | unit_cost = | ||

| production_date = | | production_date = 2012-present | ||

| number = 1,900 | | number = 1,900 | ||

| variants = | | variants = | ||

| Line 123: | Line 123: | ||

Like the JCh-6, the JCh-5.5 reloads from a dual autoloader: the bustle autoloader carries 14 unitary rounds, and the carousel carries 28 two-piece rounds, for a total of 42. The hull ammunition storage is left empty to save weight and reduce the probability of a cookoff, though the design of the carousel autoloader results in a high probability of ammunition fire if the hull is penetrated. As on contemporary Menghean MBTs, the main advantage of the dual autoloader arrangement is that it reduces the size of the turret bustle while also permitting a large number of ready rounds to be carried. The bustle autoloader also allows the use of unitary long-rod APFSDS ammunition and the [[YDCh-73]] gun-launched ATGM. | Like the JCh-6, the JCh-5.5 reloads from a dual autoloader: the bustle autoloader carries 14 unitary rounds, and the carousel carries 28 two-piece rounds, for a total of 42. The hull ammunition storage is left empty to save weight and reduce the probability of a cookoff, though the design of the carousel autoloader results in a high probability of ammunition fire if the hull is penetrated. As on contemporary Menghean MBTs, the main advantage of the dual autoloader arrangement is that it reduces the size of the turret bustle while also permitting a large number of ready rounds to be carried. The bustle autoloader also allows the use of unitary long-rod APFSDS ammunition and the [[YDCh-73]] gun-launched ATGM. | ||

Despite initial, erroneous reports that it does not feature a co-axial machine gun, the JCh-5.5 is in fact armed with a single [[GCh-96]]Ch 7.5×54mm GPMG, which fires through the gap between the applique mantlet armor and the right-side ERA plates, rather than through a hole in the applique mantlet armor itself. This machine gun is fed from a single belt with 3,600 rounds of ammunition. This eliminates the need for the commander to swap out individual ammunition boxes during combat, though the commander must still empty the casing and belt catching tray out the roof hatch. The commander's {{wp|remote controlled weapon station}} is identical to that of the JCh-6D and JCh-8, consisting of a 12.7mm [[SBK machine gun|GCh-75]] linked to the commander's main TV/IR optic with a secondary TV/IR optic for high-angle aiming. There are no backup manual controls for this weapon, and it is mounted on a pedestal behind the commander's cupola instead of rotating around with the cupola. | |||

===Protection=== | ===Protection=== | ||

Because it reuses the hulls of existing JCh-5 MBTs, the JCh-5.5 has the same underlying hull armor scheme. | Because it reuses the hulls of existing JCh-5 MBTs, the JCh-5.5 has the same underlying hull armor scheme. On the JCh-5G, the hull glacis is comprised of an 80mm steel outer plate, a 105mm glass textolite filler, and a 20mm steel backing plate. On the JCh-5N, used on later JCh-5.5 conversions, the outer and inner steel plates are retained but the internal filler is replaced by three evenly spaced 15mm plates of high-hardness steel. As of 2022, no JCh-5D or JCh-5R hulls have been used in JCh-5.5 rebuilds, so all JCh-5.5 units use either the JCh-5G or the JCh-5N hull armor scheme. Both of these armor schemes were considered several generations behind by 2010, but to save production costs and reuse existing materials, the JCh-5.5's designers opted to retain the original hull armor scheme rather than cutting open the glacis plate and replacing the contents. The designers did add a 30mm high-hardness applique plate on top of the hull glacis, spaced 20mm above the existing surface to yield a composite-like effect. | ||

The new turret has a core hexagonal shape, and concentrates its armor on the front surfaces. The side and rear plates, including the sides and rear of the turret bustle, are only 90mm thick, and protect against 30mm APFSDS but nothing heavier. The turret sides taper inward at 20 degrees, however, meaning that over the forward 40 degree arc the frontal armor protects the entire manned portion of the turret. The bustle is only masked by the turret frontal armor over a narrower 30 degree frontal arc, and is easily defeated by APFSDS fire outside this arc. Blowoff panels on the bustle, however, isolate any ammunition cookoff from the crew, and even at very close ranges and low obliquity enemy IFV and APC fire cannot penetrate it. | The new turret has a core hexagonal shape, and concentrates its armor on the front surfaces. The side and rear plates, including the sides and rear of the turret bustle, are only 90mm thick, and protect against 30mm APFSDS but nothing heavier. The turret sides taper inward at 20 degrees, however, meaning that over the forward 40 degree arc the frontal armor protects the entire manned portion of the turret. The bustle is only masked by the turret frontal armor over a narrower 30 degree frontal arc, and is easily defeated by APFSDS fire outside this arc. Blowoff panels on the bustle, however, isolate any ammunition cookoff from the crew, and even at very close ranges and low obliquity enemy IFV and APC fire cannot penetrate it. | ||

| Line 140: | Line 140: | ||

==Production== | ==Production== | ||

All Menghean JCh-5.5 conversions are carried out in Hall 2 of the Insŏng Machine Building Plant, which formerly produced spare parts and upgrade kits for JCh-5 tanks. By 1 April 2022, this site had produced 1,812 JCh-5.5 tanks, of which 703 were JCh-5.5Gs and 1109 were either N or N1 variants. | |||

In 2013, Menghe and [[Uskonmaa]] negotiated a joint upgrade deal for Uskonmaa's JCh-5 fleet. The new turrets, powerplants, fire-control systems, and (in some cases) replacement main guns were manufactured in Menghe at the Insŏng facility, but these parts were shipped to Uskonmaa for final assembly. Uskonmaa was also responsible for locally manufacturing the engine deck cover plates, hull glacis applique plates, and revised hull fuel tanks. The first locally-assembled tank left the production lines in 2014, and Uskonmaa's entire JCh-5 fleet had been upgraded by 2019. The assembly site in Uskonmaa remained in commission as a tank maintenance and repair center. | |||

==Variants== | ==Variants== | ||

| Line 150: | Line 152: | ||

:Production model derived from the S.815 prototype, with minor changes applied while preparing for mass production. All JCh-5.5G vehicles were converted from JCh-5G hulls, and consequently have thinner armor on the glacis plate than late-model JCh-5 tanks. | :Production model derived from the S.815 prototype, with minor changes applied while preparing for mass production. All JCh-5.5G vehicles were converted from JCh-5G hulls, and consequently have thinner armor on the glacis plate than late-model JCh-5 tanks. | ||

;JCh-5.5N | ;JCh-5.5N | ||

:Designation for the first batch of JCh-5.5 tanks rebuilt on JCh-5N hulls. | :Designation for the first batch of JCh-5.5 tanks rebuilt on JCh-5N hulls. It is externally identical to the JCh-5.5G, and uses the same conversion kit, but the underlying hull benefits from the JCh-5N's layered steel and composite glacis plate. | ||

;JCh-5.5N1 | |||

:An improved sub-variant of the JCh-5.5N. On these vehicles the turret is fitted with the [[Jŏgran-un (countermeasure)|Jŏgran-un]] {{wp|active protection system}}, including Chŏndongsori hardkill countermeasures. To compensate for the added mass, the hull glacis applique plate was not added. The JCh-5.5N1 was the first Menghean main battle tank to receive the expensive Chŏndongsori system, apparently on the reasoning that the JCh-5.5's armor was much thinner than the armor of other Menghean MBTs but it was also likely to be used by the Marine Infantry in high-risk operations against enemy light forces. The JCh-5.5N1 was produced alongside the JCh-5.5N, with N1 models delivered to the Menghean Marine Infantry and N models to regular Army units. | |||

;JCh-5.5U | |||

:Export designation for the second batch of JCh-5.5 tanks assembled in Uskonmaa. Though they use the same turret and powerplant refit kits as the JCh-5.5G and 5.5N, the second batch of Uskonmaan tanks were built on JCh-5D hulls, and therefore inherit the JCh-5D's hull glacis composite armor. As of 2022, Menghe still has not rebuilt any JCh-5D tanks to 5.5 standard, meaning that Uskonmaa's JCh-5.5Us are in theory slightly superior to Menghe's JCh-5.5Ns. | |||

==Operators== | ==Operators== | ||

* {{flag| | * {{flag|Menghe}}: 1812 units delivered as of 1 April 2022. | ||

* {{flag| | * {{flag|Uskonmaa}}: 402 units locally rebuilt between 2014 and 2019. | ||

==See also== | ==See also== | ||

Latest revision as of 23:55, 8 June 2022

| JCh-5.5 | |

|---|---|

The three major variants of the JCh-5.5 used in Menghe, as of 2022 | |

| Type | Main battle tank |

| Place of origin | Menghe |

| Service history | |

| In service | 2016-present |

| Used by | Menghe Dzhungestan |

| Wars | Innominadan Crisis Second Pan-Septentrion War |

| Production history | |

| Designer | Chikai Tank Design Institute |

| Designed | 1992-2012 |

| Manufacturer | Insŏng Machine Building Plant |

| Produced | 2012-present |

| No. built | 1,900 |

| Specifications (JCh-5.5G) | |

| Weight | 47.7 tonnes |

| Length | 9.46 m (without fuel drums) |

| length | 6.79 |

| Width | 3.58 m (turret corners) |

| Height | 2.17 m to turret roof |

| Crew | 3 (driver, gunner, commander) |

| Armor | welded steel base Composite armor (turret face and hull glacis) |

Main armament | 125mm L/48 smoothbore gun |

Secondary armament | 12.7mm GCh-75Ch HMG (commander) 7.5mm GCh-77 MMG (co-axial) |

| Engine | MTU 10V 890 powerpack 920 kW (1250 hp) |

| Power/weight | 26.2 hp/tonne |

| Suspension | torsion-bar |

| Ground clearance | 40 cm |

Operational range | 850 km |

| Speed | 70 km/h (road) |

JCh-5.5 is the final designation given to an interim main battle tank consisting of a JCh-5 hull with an all-new welded turret and bustle autoloader. It is a hybrid design combining features of the JCh-5 and JCh-6, hence its unconventional 5.5 designation. It was also known under the prototype designations S.804 and S.815. All JCh-5.5 tanks are factory rebuilds of existing JCh-5 vehicles, with the old turret removed, the hull internals refurbished, and the new turret installed in place.

Development

S.804

S.804, or Sije Charyang 804 (prototype vehicle 804), was the first design in the evolution of the JCh-5.5. It was developed in the 1990s, initially as a low-priority side project by the Chikai Tank Design Bureau. In 1996 engineers at Chikai pulled a JCh-5D from the assembly line and completed it with the changes spelled out in prior design work, resulting in the first and only operational S.804 prototype. This prototype was never fitted with ERA tiles, as it was only built to prove the viability of the underlying concept, but it would have been fitted with ERA if accepted for service.

The S.804 design was very similar to the JCh-5, owing to its improvised construction, but did incorporate one important difference: a 14-round bustle autoloader installed in a box on the rear of the turret. This allowed the tank to carry full-length unitary 125mm ammunition, which in turn would allow the development of longer APFSDS penetrators. The carousel autoloader was retained, but it would only be loaded with HE, HEAT, and ATGM ammunition. The autoloader was thinly armored, protected against shrapnel and 12.7mm HMG fire but not autocannon or tank fire, but it featured blowoff panels on its roof and the turret rear armor served as a form of protective bulkhead for the crew.

The Menghean Army showed some interest in the new vehicle, but the Ministry of National Defense did not ultimately accept it for service. In particular, MoND evaluators appointed by the Army were concerned about the thin armor around the turret bustle and mechanical problems in loading tests. Some Army staff also advocated for developing an entirely new main battle tank, which would allow them to address many other issues with the JCh-5. This new main battle tank became the JCh-6, which drew heavily on the S.804's basic configuration but was ultimately an entirely different vehicle. With the JCh-6 program receiving MoND approval, the S.804 project was shelved, only to see new life over a decade later as the S.815.

S.815

Sije-Charyang 815 was Chikai's second attempt at designing a JCh-5 variant with a bustle autoloader capable of handling unitary 125mm APFSDS ammunition. Its development process began after the JCh-6 had already entered service, and it made use of many spinoff technologies from the contemporary JCh-8 project, which also produced the JCh-6D main battle tank.

This time around, Chikai designed the S.815 not as a new-production successor to the JCh-6, but rather as a rebuild kit which could keep JCh-5 hulls relevant for decades to come. To maximize efficiency in this regard, the Ministry of National Defense ordered that the first batch of vehicles be based on JCh-5G hulls; as the oldest of the JCh-5 models, the 5G was the most obsolete, especially with regard to its turret geometry and fire control.

Beyond its use of existing hulls, the JCh-5.5 concept regained currency in the early 2010s because of its lighter weight. With reactive armor kits fitted, the JCh-6G1 and JCh-6N reached a mass of over 52 tonnes, and the JCh-6D then in development was on track to surpass 55 tonnes. While this was acceptable on most parts of the land border facing Maverica, the heavier weight and larger size of the JCh-6 made it harder to transport by air or by sea. The Menghean Navy's Marine Infantry were especially interested in the concept of an upgraded JCh-5, as the JCh-6 was so heavy that existing tank landing ships would not be able to transport an entire tank company to the beachhead.

The first S.815 prototype was built in 2012, and tested that year and the next. A small number were delivered in early 2014, seeing service in the Innominadan Crisis with the 2nd Marine Infantry Brigade.

Description

Armament

The main armament of the JCh-5.5 is a 125mm L/46 gun, the same type used on the "G" and "N" models of the JCh-6. The heavier 125mm L/57 of the JCh-6D was also considered, but the L/46 was ultimately selected due to its smaller size, mass, and forward surface area. The gun can elevate to +13.5 degrees or depress to -6.1 degrees, a slightly more limited range than that of the JCh-5.

Like the JCh-6, the JCh-5.5 reloads from a dual autoloader: the bustle autoloader carries 14 unitary rounds, and the carousel carries 28 two-piece rounds, for a total of 42. The hull ammunition storage is left empty to save weight and reduce the probability of a cookoff, though the design of the carousel autoloader results in a high probability of ammunition fire if the hull is penetrated. As on contemporary Menghean MBTs, the main advantage of the dual autoloader arrangement is that it reduces the size of the turret bustle while also permitting a large number of ready rounds to be carried. The bustle autoloader also allows the use of unitary long-rod APFSDS ammunition and the YDCh-73 gun-launched ATGM.

Despite initial, erroneous reports that it does not feature a co-axial machine gun, the JCh-5.5 is in fact armed with a single GCh-96Ch 7.5×54mm GPMG, which fires through the gap between the applique mantlet armor and the right-side ERA plates, rather than through a hole in the applique mantlet armor itself. This machine gun is fed from a single belt with 3,600 rounds of ammunition. This eliminates the need for the commander to swap out individual ammunition boxes during combat, though the commander must still empty the casing and belt catching tray out the roof hatch. The commander's remote controlled weapon station is identical to that of the JCh-6D and JCh-8, consisting of a 12.7mm GCh-75 linked to the commander's main TV/IR optic with a secondary TV/IR optic for high-angle aiming. There are no backup manual controls for this weapon, and it is mounted on a pedestal behind the commander's cupola instead of rotating around with the cupola.

Protection

Because it reuses the hulls of existing JCh-5 MBTs, the JCh-5.5 has the same underlying hull armor scheme. On the JCh-5G, the hull glacis is comprised of an 80mm steel outer plate, a 105mm glass textolite filler, and a 20mm steel backing plate. On the JCh-5N, used on later JCh-5.5 conversions, the outer and inner steel plates are retained but the internal filler is replaced by three evenly spaced 15mm plates of high-hardness steel. As of 2022, no JCh-5D or JCh-5R hulls have been used in JCh-5.5 rebuilds, so all JCh-5.5 units use either the JCh-5G or the JCh-5N hull armor scheme. Both of these armor schemes were considered several generations behind by 2010, but to save production costs and reuse existing materials, the JCh-5.5's designers opted to retain the original hull armor scheme rather than cutting open the glacis plate and replacing the contents. The designers did add a 30mm high-hardness applique plate on top of the hull glacis, spaced 20mm above the existing surface to yield a composite-like effect.

The new turret has a core hexagonal shape, and concentrates its armor on the front surfaces. The side and rear plates, including the sides and rear of the turret bustle, are only 90mm thick, and protect against 30mm APFSDS but nothing heavier. The turret sides taper inward at 20 degrees, however, meaning that over the forward 40 degree arc the frontal armor protects the entire manned portion of the turret. The bustle is only masked by the turret frontal armor over a narrower 30 degree frontal arc, and is easily defeated by APFSDS fire outside this arc. Blowoff panels on the bustle, however, isolate any ammunition cookoff from the crew, and even at very close ranges and low obliquity enemy IFV and APC fire cannot penetrate it.

The turret frontal armor uses composite modules similar in style to those of the JCh-6D, though the geometry is different and the composite modules are thinner. Unofficial measurements put the line-of-sight thickness at 860mm for a head-on impact and 745mm for an impact at 30 degrees off centerline, and official Menghean sources claim that the base armor is able to withstand two-piece 125mm APFSDS ammunition from T-74 tanks. As on the JCh-8 and JCh-6D, the composite armor modules can be lifted off the turret with the help of a crane, allowing a combat unit to replace damaged armor plates in the field.

As a supplemental measure, the turret and hull are fitted with Generation 2 reactive armor modules. Though the Generation 3 ERA system was already available when the JCh-5.5 entered service, the Generation 2 system was judged more weight-efficient, and later combat experience found that it was moderately more effective as well. Additionally, the JCh-5.5 carries the softkill active protection system used by the JCh-6N, with laser dazzlers and an automatic smoke deployment mode.

Mobility

The JCh-5.5 is powered by an MTU 10V 890 powerpack which generates 920 kW (1250 hp) of power. This was installed in place of the original engine during reconstruction, with a new engine deck and rear hull plate installed in place of the original ones. The new powerpack is able to fit in the same amount of space as the original engine and transmission, but it generates over 30% more power, resulting in better speed and mobility than the JCh-5D despite the added weight. As on the JCh-6, the entire powerpack can be removed by crane in the field, accelerating maintenance compared to the original engine, which could take several hours to remove entirely.

As a result of its added equipment and armor, the JCh-5.5 has a total mass of 47.7 metric tonnes. This brings its power-to-weight ratio to a respectable 26.2 horsepower per tonne and its ground pressure to 91 kPa. It has a maximum road speed of 70 kilometers per hour, and an operational range of 850 kilometers with external fuel drums fitted.

Production

All Menghean JCh-5.5 conversions are carried out in Hall 2 of the Insŏng Machine Building Plant, which formerly produced spare parts and upgrade kits for JCh-5 tanks. By 1 April 2022, this site had produced 1,812 JCh-5.5 tanks, of which 703 were JCh-5.5Gs and 1109 were either N or N1 variants.

In 2013, Menghe and Uskonmaa negotiated a joint upgrade deal for Uskonmaa's JCh-5 fleet. The new turrets, powerplants, fire-control systems, and (in some cases) replacement main guns were manufactured in Menghe at the Insŏng facility, but these parts were shipped to Uskonmaa for final assembly. Uskonmaa was also responsible for locally manufacturing the engine deck cover plates, hull glacis applique plates, and revised hull fuel tanks. The first locally-assembled tank left the production lines in 2014, and Uskonmaa's entire JCh-5 fleet had been upgraded by 2019. The assembly site in Uskonmaa remained in commission as a tank maintenance and repair center.

Variants

- S.804

- Prototype vehicle with a 14-round bustle autoloader fitted to the turret of a JCh-5D tank. Tested in 1996, but not approved for mass production.

- S.815

- Prototype vehicle first tested in 2009. It formed the basis for the JCh-5.5G production variant.

- JCh-5.5G

- Production model derived from the S.815 prototype, with minor changes applied while preparing for mass production. All JCh-5.5G vehicles were converted from JCh-5G hulls, and consequently have thinner armor on the glacis plate than late-model JCh-5 tanks.

- JCh-5.5N

- Designation for the first batch of JCh-5.5 tanks rebuilt on JCh-5N hulls. It is externally identical to the JCh-5.5G, and uses the same conversion kit, but the underlying hull benefits from the JCh-5N's layered steel and composite glacis plate.

- JCh-5.5N1

- An improved sub-variant of the JCh-5.5N. On these vehicles the turret is fitted with the Jŏgran-un active protection system, including Chŏndongsori hardkill countermeasures. To compensate for the added mass, the hull glacis applique plate was not added. The JCh-5.5N1 was the first Menghean main battle tank to receive the expensive Chŏndongsori system, apparently on the reasoning that the JCh-5.5's armor was much thinner than the armor of other Menghean MBTs but it was also likely to be used by the Marine Infantry in high-risk operations against enemy light forces. The JCh-5.5N1 was produced alongside the JCh-5.5N, with N1 models delivered to the Menghean Marine Infantry and N models to regular Army units.

- JCh-5.5U

- Export designation for the second batch of JCh-5.5 tanks assembled in Uskonmaa. Though they use the same turret and powerplant refit kits as the JCh-5.5G and 5.5N, the second batch of Uskonmaan tanks were built on JCh-5D hulls, and therefore inherit the JCh-5D's hull glacis composite armor. As of 2022, Menghe still has not rebuilt any JCh-5D tanks to 5.5 standard, meaning that Uskonmaa's JCh-5.5Us are in theory slightly superior to Menghe's JCh-5.5Ns.

Operators

Menghe: 1812 units delivered as of 1 April 2022.

Menghe: 1812 units delivered as of 1 April 2022.- Template:Country data Uskonmaa: 402 units locally rebuilt between 2014 and 2019.