PaVå-33: Difference between revisions

| (3 intermediate revisions by the same user not shown) | |||

| Line 69: | Line 69: | ||

=== Protection === | === Protection === | ||

The PaVå-33 uses a {{wpl|Composite_armour|composite armor}} scheme known as Arendal Spesiell Komposisjon (or Arendal for short). Arendal was | The PaVå-33 uses a {{wpl|Composite_armour|composite armor}} scheme known as Arendal Spesiell Komposisjon (or Arendal for short). Arendal was, at the time of its introduction, a novel armor scheme consisting of extremely hard and brittle ceramic tiles encased within a steel framework. These ceramic tiles, each of which are hexagonal in shape and approximately 30mm in thickness and 25mm in width, are {{wpl|Powder_metallurgy#Isostatic_powder_compacting|isostatically pressed}} into the heated metal matrix. Behind this array is a plate of solid {{wpl|Rolled_homogeneous_armour|RHA steel}}, which reinforces the ceramic tiles from behind and prevents deformation of the composite array from high-energy impacts. The thickness required of the plate, combined with the need to cover the entire rear "face" of the array, results in a plate that weighs half as much as the entire array itself. This combination of array and backing plate creates a composite layer approximately 90 mm thick, which is then repeated several times. Each composite layer is separated by elastic inserts, which help to protect the composite layers from being damaged by impact shock and intense vibrations. | ||

This type of armor array has two principal mechanisms that it uses to defeat incoming penetrators. The first applies against lightweight, extremely high velocity {{wpl|kinetic energy penetrators}}. At high impact velocities, the lightweight penetrator shatters upon contact with the very high-hardness ceramic tiles instead of penetrating, as it would against homogeneous armor. Additionally, pulverized ceramic tiles have a significant abrasive effect against kinetic penetrators that manage to perforate the plate without shattering. The second applies against {{wpl|shaped charge}} penetrators, and is also a result of the physical properties of the ceramic tiles. When the molten metal jet of a shaped charge impacts the ceramic tiles, the brittleness of the tile causes the entrance channel of the jet to become jagged. This results in severe asymmetric pressures on the jet as it penetrates, which disrupts the geometry of the jet and significantly reduces its penetrative capabilities. Multiple layers of composite arrays enhance this effect, as the disrupted jet creates even greater irregularities in subsequent arrays, which in turn creates greater disruptive pressure. Additionally, the elastic layers between each array will deform and expand in the event of a penetration, further reducing the penetrative capabilities of both types of penetrators through a similar mechanism to {{wpl|Reactive_armour#Non-explosive_and_non-energetic_reactive_armour|non-energetic reactive armor}}. All-together, this type of composite armor is several times more effective by mass than homogeneous steel armor against shaped charge penetrators, and moderately more effective by mass against kinetic energy penetrators. | This type of armor array has two principal mechanisms that it uses to defeat incoming penetrators. The first applies against lightweight, extremely high velocity {{wpl|kinetic energy penetrators}}. At high impact velocities, the lightweight penetrator shatters upon contact with the very high-hardness ceramic tiles instead of penetrating, as it would against homogeneous armor. Additionally, pulverized ceramic tiles have a significant abrasive effect against kinetic penetrators that manage to perforate the plate without shattering. The second applies against {{wpl|shaped charge}} penetrators, and is also a result of the physical properties of the ceramic tiles. When the molten metal jet of a shaped charge impacts the ceramic tiles, the brittleness of the tile causes the entrance channel of the jet to become jagged. This results in severe asymmetric pressures on the jet as it penetrates, which disrupts the geometry of the jet and significantly reduces its penetrative capabilities. Multiple layers of composite arrays enhance this effect, as the disrupted jet creates even greater irregularities in subsequent arrays, which in turn creates greater disruptive pressure. Additionally, the elastic layers between each array will deform and expand in the event of a penetration, further reducing the penetrative capabilities of both types of penetrators through a similar mechanism to {{wpl|Reactive_armour#Non-explosive_and_non-energetic_reactive_armour|non-energetic reactive armor}}. All-together, this type of composite armor is several times more effective by mass than homogeneous steel armor against shaped charge penetrators, and moderately more effective by mass against kinetic energy penetrators. | ||

| Line 87: | Line 87: | ||

The PaVå-33 uses the ATI CDM12T V12 turbo-diesel engine. This engine is a more conventional design compared to the {{wpl|Two-stroke_engine|two-stroke}} {{wpl|Opposed-piston_engine|opposed piston}} {{wpl|multifuel}} diesel engine used in the PaVå-22. The multifuel requirement for the engine was dropped for the development of the CDM12T, as even in combat conditions the PaVå-22 almost never made use of the multifuel capabilities of its engine. Without the compromises required by a multifuel engine, the CDM12T could be rated for a much higher power output. The 26.1L engine achieves a maximum power of 1500 hp at 2300 rpm. This results in a power to weight ratio of 23.6 hp/t at an expected combat configuration, which is more than double that of its predecessor. | The PaVå-33 uses the ATI CDM12T V12 turbo-diesel engine. This engine is a more conventional design compared to the {{wpl|Two-stroke_engine|two-stroke}} {{wpl|Opposed-piston_engine|opposed piston}} {{wpl|multifuel}} diesel engine used in the PaVå-22. The multifuel requirement for the engine was dropped for the development of the CDM12T, as even in combat conditions the PaVå-22 almost never made use of the multifuel capabilities of its engine. Without the compromises required by a multifuel engine, the CDM12T could be rated for a much higher power output. The 26.1L engine achieves a maximum power of 1500 hp at 2300 rpm. This results in a power to weight ratio of 23.6 hp/t at an expected combat configuration, which is more than double that of its predecessor. | ||

This engine is paired to an 8 speed automatic transmission with 6 forward and 2 reverse gears. The first gear in both forward and reverse motion is a short gear intended to provide large amounts of low end power to assist the tank in freeing itself from being stuck. | This engine is paired to an 8 speed automatic transmission with 6 forward and 2 reverse gears. The first gear in both forward and reverse motion is a short gear intended to provide large amounts of low end power to assist the tank in freeing itself from being stuck. This combination gives a maximum on-road speed of 72 km/h, which is the electrically limited maximum speed of the tank to prevent excess drivetrain and track wear. In cross-country travel, it is generally expected to achieve around 50 km/h, but this will vary based on terrain conditions. The maximum reverse speed of the vehicle is approximately 32 km/h. | ||

The PaVå-33 makes use of a {{wpl|Hydropneumatic_suspension|hydrogas}} suspension system. This kind of suspension makes use of a hydraulic fluid and a compressible gas contained within a piston instead of a more conventional mechanical suspension. When operating, the hydraulic fluid transfers pressure from it to a connector piston on the roadwheel arms. The resistance of the suspension unit is dependent on the compressibility of the gas, and as such possesses highly non-linear characteristics when under load. This allows the use of a lower “natural” suspension frequency than suspensions based on metallic springs. For the PaVå-33, this frequency is 0.75 Hz compared to the more usual 1-1.5 Hz of conventional suspension systems. When combined with a relatively large road wheel travel distance of 450 mm, this gives the PaVå-33 exceptional cross-country performance. This kind of suspension unit also acts both as a spring and a {{wpl|Shock_absorber|damper}}, which means that each roadwheel is fitted with a damper. This makes it more effective at smoothing out bumps from suspension travel than vehicles where only some road wheels are equipped with dampers. | The PaVå-33 makes use of a {{wpl|Hydropneumatic_suspension|hydrogas}} suspension system. This kind of suspension makes use of a hydraulic fluid and a compressible gas contained within a piston instead of a more conventional mechanical suspension. When operating, the hydraulic fluid transfers pressure from it to a connector piston on the roadwheel arms. The resistance of the suspension unit is dependent on the compressibility of the gas, and as such possesses highly non-linear characteristics when under load. This allows the use of a lower “natural” suspension frequency than suspensions based on metallic springs. For the PaVå-33, this frequency is 0.75 Hz compared to the more usual 1-1.5 Hz of conventional suspension systems. When combined with a relatively large road wheel travel distance of 450 mm, this gives the PaVå-33 exceptional cross-country performance. This kind of suspension unit also acts both as a spring and a {{wpl|Shock_absorber|damper}}, which means that each roadwheel is fitted with a damper. This makes it more effective at smoothing out bumps from suspension travel than vehicles where only some road wheels are equipped with dampers. | ||

| Line 109: | Line 109: | ||

* PaVå-33 - Original production variant, produced 1986-1990 | * PaVå-33 - Original production variant, produced 1986-1990 | ||

* PaVå-33E1 - New radio with improved counter-ECM capabilities. Addition of a {{wpl|Enhanced_Position_Location_Reporting_System|radio position and reporting system}}. Replacement of all night vision optics with third generation night vision devices. Produced 1990-1994. | * PaVå-33E1 - New radio with improved counter-ECM capabilities. Addition of a {{wpl|Enhanced_Position_Location_Reporting_System|radio position and reporting system}}. Replacement of all night vision optics with third generation night vision devices. Produced 1990-1994. | ||

* PaVå-33E2 - Introduction of the Rustningsforbedringspakke (RFS) armor enhancement package, using improved composite composition and depleted uranium inserts. Conferred a weight increase of approximately 4t compared to the original combat armor package. Option to replace commander’s remote machine gun with a {{wpl|FN_BRG-15|InMg-74}}. Produced 1997- | * PaVå-33E2 - Introduction of the Rustningsforbedringspakke (RFS) armor enhancement package, using improved composite composition and depleted uranium inserts. Conferred a weight increase of approximately 4t compared to the original combat armor package. Option to replace commander’s remote machine gun with a {{wpl|FN_BRG-15|InMg-74}}. Produced 1997-2007. All preceding vehicles would be upgraded to this standard by 2007, or converted into other specialized variants. | ||

* PaVå-33E3 - Modernization of fire control systems, including improved thermal sights and a new ballistic computer. Addition of fittings for an [[FFLS_Fjernstyrt_Tårn|FjT-1]] remote weapon station. Produced 2008-present. | * PaVå-33E3 - Modernization of fire control systems, including improved thermal sights and a new ballistic computer. Addition of fittings for an [[FFLS_Fjernstyrt_Tårn|FjT-1]] remote weapon station. Produced 2008-present. | ||

| Line 115: | Line 115: | ||

* PaIn-33 - Armored Engineering vehicle, with a modular equipment load. Capable for use in mine and obstacle clearing, tracklaying, bridgelaying, and fortification construction. | * PaIn-33 - Armored Engineering vehicle, with a modular equipment load. Capable for use in mine and obstacle clearing, tracklaying, bridgelaying, and fortification construction. | ||

* PaGj-33 - Armored recovery vehicle. | * PaGj-33 - Armored recovery vehicle. | ||

== Operators == | == Operators == | ||

* {{flag|Trinovantum}} | * {{flag|Trinovantum}} | ||

== See Also == | == See Also == | ||

* {{ | * {{flagicon|Ostlichtor}} [[Panzerkampfwagen XI]] | ||

* {{ | * {{flagicon|Notreceau}} [[AVS 54]] | ||

[[Category:Trinovantum]] | [[Category:Trinovantum]] | ||

[[Category:Trinovantan Military]] | [[Category:Trinovantan Military]] | ||

[[Category: Weapon Systems in Annwynn]] | [[Category: Weapon Systems in Annwynn]] | ||

Latest revision as of 19:33, 24 December 2023

| PaVå-33 | |

|---|---|

An early production PaVå-33. | |

| Type | Main Battle Tank |

| Place of origin | |

| Service history | |

| Used by | |

| Production history | |

| Designer | Militært Kjøretøyteknisk Institutt |

| Designed | 1978-1983 |

| Manufacturer | ATI |

| Unit cost | 2.15 million kroner (1986) |

| Produced | 1986-Present |

| Specifications | |

| Weight | 54.6 tonnes (60.2 short tons; 53.7 long tons) 63.6 tonnes (70.1 short tons; 62.6 long tons) combat 67.3 tonnes (74.2 short tons; 66.2 long tons) RFS (rustningsforbedringspakke) |

| Length | 9.3 m (30 ft 6 in) gun forward 7.4 m (24 ft 3 in) hull |

| Width | 3.5 m (11 ft 6 in) |

| Height | 2.45 m (8 ft 0 in) |

| Crew | 4 (commander, gunner, loader, driver) |

| Armor | Composite |

Main armament | 1x KjK-74 120mm rifled cannon |

Secondary armament | 1x coaxial KjMg-73 7.2mm chaingun 1x remote InMg-43 7.2mm machine gun |

| Engine | 26.1 L ATI CDM12T V12 turbo-diesel 1500 hp @ 2300 rpm |

| Power/weight | 23.6 hp/t combat 22.3 hp/t RFS |

| Transmission | automatic (6 forward, 2 reverse) |

| Suspension | hydrogas suspension |

| Fuel capacity | 1,180 L (310 US gal) |

Operational range | 400 km (250 mi) |

| Speed | 72 km/h (45 mph) on road approx 50 km/h (31 mph) cross country |

The PaVå-33 is a Trinovantan universal tank and the primary service tank of the Trinovantan military. It was designed by the Militært Kjøretøyteknisk Institutt, which normally designs engineering and technology testbed vehicles. It is primarily produced at Askeladd AG’s Larvik Tungtraktorfabrikk. Designed during the Fifth Ostlander-Trinovantan War, the PaVå-33 replaced the preceding PaVå-22 after the war’s conclusion.

At the time it was designed, the PaVå-33 featured several advanced features for a tank. However, this advanced design was also significantly more expensive and time-consuming to produce than its predecessor. The final production version of the PaVå-33 cost 5 times more than the PaVå-22, and required nearly 3 times as many man hours to produce. Were it not for the poor performance of the PaVå-22 during the Fifth Ostlander-Trinovantan War, the PaVå-33 would have likely been canceled on the grounds of its cost.

Development

The origin of the PaVå-33 lies in the middle of the Fifth Ostlander-Trinovantan War. While attempts had been made to replace the aging PaVå-22 had been undertaken before the war, none of these proposals were seen as necessary as the PaVå-22 was considered more than a match for Ostlichtor’s PanzerKampfwagen IX tanks. However, this view was formed based on comparisons with older Pz IX Ausf.A models, and not the more recent Ausf. D models that made up the bulk of Ostlichtor’s armored forces at the time of the war. These improved models featured a modern gun stabilizer, superior fire control systems, and improved night fighting equipment. While the Pz IX remained a lightly armored vehicle and thus was vulnerable to the PaVå-22’s gun, advancements in Ostlichtor’s ammunition production had allowed the older 105mm gun to greatly extend its effective combat range against the PaVå-22. Thus, tank battles during the war were often decided by which side could successfully strike their target first. In this, the Pz IX’s higher mobility and more modern fire control systems gave it an advantage over Trinovantum’s tanks in most engagements.

Further complicating matters was the proliferation of high-explosive anti-tank threats, against which the PaVå-22’s homogeneous steel armor performed poorly against. Infantry and light vehicles proved to be an unexpectedly lethal threat, with light anti-tank rockets and heavier anti-tank guided missiles causing a large number of losses over the course of the war.

As these factors became obvious, a new program to develop a replacement for the PaVå-22 was initiated. Factors identified as critical issues for the new vehicle to address were protection against chemical energy threats, inferior fire control capabilities, and poor mobility. During the initial concept work for what would become the PaVå-33, Ostlichtor’s Panzerkampfwagen XI began making appearances in the war. This new tank had far superior protection compared to both the preceding Pz. IX and even the PaVå-22, while being equivalent or superior to the Pz. IX in most other considerations. This would result in an escalation of the requirements for the PaVå-22’s replacement, additionally prompting the development of a new gun to equip the future vehicle with.

Development of the vehicle would continue after the war, with the first pre-production testing vehicles being made after the conclusion of the war. The vehicle would ultimately enter production in 1986.

Design

Armament

The primary weapon of the PaVå-33 is the KjK-74 120mm rifled cannon. It is derived from the previous KjK-55 120mm rifled cannon that equipped the PaVå-22, and is compatible with the two-piece ammunition previously developed for that weapon. The new cannon differs from its predecessor in the use of a reinforced split-block breach and electroslag remelting barrel construction. This significantly improved the effective barrel life, going from 120 effective full charges to over 400. The reinforced breech and barrel construction allowed for the development of even higher pressure ammunition to better overcome the improved armor of Ostlichtor’s Panzerkampfwagen XI.

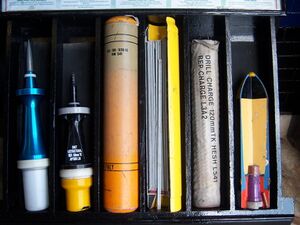

Two new APFSDS rounds were developed alongside the PaVå-33. Both were constructed of a denser depleted uranium alloy instead of the tungsten alloy of preceding ammunition. The first projectile, designated Mk.22, used a reduced propellant charge that makes it compatible with older guns. The second projectile, designated Mk.23, had an increased length and used a more powerful propellant charge. The Mk.23 round is considered not safe for use in the older KjK-55 gun and thus is only issued to the PaVå-33. The Mk.22 conferred an approximately 6% increase in penetration, with superior post-penetration effects compared to the older tungsten ammunition. The Mk.23 was approximately 27% more effective than the tungsten ammunition, which makes it capable of defeating Ostlichtor’s Panzerkampfwagen XI at range.

The general purpose munition carried by the PaVå-33 is the Mk.7E5 HESH round, retained from the previous KjK-55 gun. This round is fired with a lower pressure bag charge, akin to that of an artillery shell. While most other nations moved to smoothbore guns firing HEAT ammunition for their general purpose ammunition, it was determined by Trinovantan military designers that gun-fired HEAT ammunition was no better at defeating groups of infantry than HESH ammunition and was markedly worse at defeating structures and fortifications. In terms of anti-armor capabilities, the explosive content of HESH was generally enough to disable vehicles in the 25t and lower weight class with a direct hit even without the spalling effect this ammunition is known for. Any modern vehicle significantly heavier than that was likely to feature ERA and/or composite armor, and thus be similarly protected against HEAT as it would be against HESH. This preference for the use of HESH ammunition is why the KjK-74 was developed from the onset as a rifled cannon.

Additional special-purpose ammunition is available, mostly from older stocks created for the PaVå-22. This includes obscuring white phosphorous smoke rounds, illumination rounds, and anti-personnel canister shells. The PaVå-33 has stowage space for 45 rounds and their respective propellant charges.

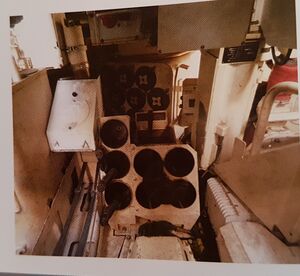

A KjMg-73 7.2mm chain gun is mounted coaxially to the main gun and controlled by the gunner, intended for the suppression of infantry and other unarmored targets. It feeds from a belt box capable of holding 2000 rounds of ammunition ready to fire, with storage for a single reload in a hull compartment. The choice of a chain gun was made due to concerns of propellant gas filling the chamber during NBC operations, which can prevent proper ventilation of such gasses. The vehicle’s fire control system works with this weapon system, allowing it to be accurate at even extreme ranges for the caliber of weapon. A InMg-43 7.2mm general purpose machine gun is also present in a remote-controlled mount on the commander’s hatch. This is fed from standard 100 round belt boxes.

Protection

The PaVå-33 uses a composite armor scheme known as Arendal Spesiell Komposisjon (or Arendal for short). Arendal was, at the time of its introduction, a novel armor scheme consisting of extremely hard and brittle ceramic tiles encased within a steel framework. These ceramic tiles, each of which are hexagonal in shape and approximately 30mm in thickness and 25mm in width, are isostatically pressed into the heated metal matrix. Behind this array is a plate of solid RHA steel, which reinforces the ceramic tiles from behind and prevents deformation of the composite array from high-energy impacts. The thickness required of the plate, combined with the need to cover the entire rear "face" of the array, results in a plate that weighs half as much as the entire array itself. This combination of array and backing plate creates a composite layer approximately 90 mm thick, which is then repeated several times. Each composite layer is separated by elastic inserts, which help to protect the composite layers from being damaged by impact shock and intense vibrations.

This type of armor array has two principal mechanisms that it uses to defeat incoming penetrators. The first applies against lightweight, extremely high velocity kinetic energy penetrators. At high impact velocities, the lightweight penetrator shatters upon contact with the very high-hardness ceramic tiles instead of penetrating, as it would against homogeneous armor. Additionally, pulverized ceramic tiles have a significant abrasive effect against kinetic penetrators that manage to perforate the plate without shattering. The second applies against shaped charge penetrators, and is also a result of the physical properties of the ceramic tiles. When the molten metal jet of a shaped charge impacts the ceramic tiles, the brittleness of the tile causes the entrance channel of the jet to become jagged. This results in severe asymmetric pressures on the jet as it penetrates, which disrupts the geometry of the jet and significantly reduces its penetrative capabilities. Multiple layers of composite arrays enhance this effect, as the disrupted jet creates even greater irregularities in subsequent arrays, which in turn creates greater disruptive pressure. Additionally, the elastic layers between each array will deform and expand in the event of a penetration, further reducing the penetrative capabilities of both types of penetrators through a similar mechanism to non-energetic reactive armor. All-together, this type of composite armor is several times more effective by mass than homogeneous steel armor against shaped charge penetrators, and moderately more effective by mass against kinetic energy penetrators.

Arendal composite protects the entire frontal arc of the tank, including the turret face and lower hull. Heavy composite side-skirts are installed on the forward sections of the hull to provide protection against angled shots into the side hull. This arrangement provides near-comprehensive protection against kinetic and chemical energy threats from the frontal arc. It is capable of resisting 120mm projectiles from the KjK-74, which has similar anti-armor performance to the 128mm L/40 gun used by Ostlichtor’s Pz.XI, from up to 25 degrees from the front. The armor array also resisted frontal attacks from several HEAT warheads, including the powerful 170mm HEAT warhead used in the GMoPø-22 ATGM. The turret sides are also protected by Arendal composites, giving them resistance against most infantry portable light anti-tank rockets and up to 20mm APDS rounds. The hull sides and rear are protected against 14.5mm AP rounds and shell fragmentation.

The construction of the hull makes use of military-grade aluminium alloy as a weight saving measure in order to meet the military’s maximum weight requirement. Portions of the hull unlikely to receive weapons fire, such as the sides rearward of the fighting compartment, the hull rear, and the bottom make extensive use of aluminium in their construction. The aluminium hull portions are bonded to the steel portions through the use of explosive welding. This welding technique produces very strong bonds between the two metals that are incompatible to more conventional welding methods.

Propellant charges for the main gun are stored in wet storage compartments in the hull floor, with each propellant charge surrounded by a liquid mixture to inhibit fire. In the event of a penetration into the propellant stores the liquid container would burst and quench the propellant charges, limiting the possibility for a catastrophic ignition of the volatile propellant charges.

The vehicle is capable of operating in environments under NBC threat. It features sensors capable of detecting and alerting the crew to presence of chemical or radiological threats. The fighting compartment is fully ventilated and fitted with an overpressure system to prevent the incursion of harmful contaminants into the crewed space. Critical electronics are given additional shielding against radiological and electromagnetic threats beyond what the hull of the vehicle naturally provides, in order to allow for continued use of its fire control and communications equipment during nuclear conflicts.

Some basic measures at thermal signature mitigation are also present on the vehicle. The hot exhaust from the engine is mixed with and cooled by outside air before being expelled by the vehicle. The exhaust ports vent over the tracks of the vehicle, which can more effectively sink the added heat by their contact with the ground.

Mobility

The PaVå-33 uses the ATI CDM12T V12 turbo-diesel engine. This engine is a more conventional design compared to the two-stroke opposed piston multifuel diesel engine used in the PaVå-22. The multifuel requirement for the engine was dropped for the development of the CDM12T, as even in combat conditions the PaVå-22 almost never made use of the multifuel capabilities of its engine. Without the compromises required by a multifuel engine, the CDM12T could be rated for a much higher power output. The 26.1L engine achieves a maximum power of 1500 hp at 2300 rpm. This results in a power to weight ratio of 23.6 hp/t at an expected combat configuration, which is more than double that of its predecessor.

This engine is paired to an 8 speed automatic transmission with 6 forward and 2 reverse gears. The first gear in both forward and reverse motion is a short gear intended to provide large amounts of low end power to assist the tank in freeing itself from being stuck. This combination gives a maximum on-road speed of 72 km/h, which is the electrically limited maximum speed of the tank to prevent excess drivetrain and track wear. In cross-country travel, it is generally expected to achieve around 50 km/h, but this will vary based on terrain conditions. The maximum reverse speed of the vehicle is approximately 32 km/h.

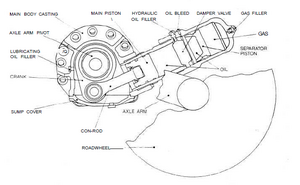

The PaVå-33 makes use of a hydrogas suspension system. This kind of suspension makes use of a hydraulic fluid and a compressible gas contained within a piston instead of a more conventional mechanical suspension. When operating, the hydraulic fluid transfers pressure from it to a connector piston on the roadwheel arms. The resistance of the suspension unit is dependent on the compressibility of the gas, and as such possesses highly non-linear characteristics when under load. This allows the use of a lower “natural” suspension frequency than suspensions based on metallic springs. For the PaVå-33, this frequency is 0.75 Hz compared to the more usual 1-1.5 Hz of conventional suspension systems. When combined with a relatively large road wheel travel distance of 450 mm, this gives the PaVå-33 exceptional cross-country performance. This kind of suspension unit also acts both as a spring and a damper, which means that each roadwheel is fitted with a damper. This makes it more effective at smoothing out bumps from suspension travel than vehicles where only some road wheels are equipped with dampers.

The suspension units for each roadwheel are self-contained and mounted external to the hull, which allows for relatively quick and easy replacement and maintenance of the vehicle’s suspension.

Sensors and Systems

The PaVå-33 featured an advanced fire control system for its time which included a digital ballistic computer, environmental conditions sensors, multiple independent laser rangefinders and thermal imagers, advanced night-fighting equipment, and dual controls for both commander and gunner. Many of these features would become standard for Trinovantan vehicles going forward. The digital fire control computer takes information from the laser rangefinders, the muzzle reference sensor, environmental sensors, and the selected choice of ammunition and rapidly produces a firing solution with a high degree of first-hit accuracy. The gun has two-plane stabilization which, combined with the vehicle’s cross country driving characteristics, minimizes the loss of accuracy when firing on the move.

The gunner’s station includes an armored day/night thermal sight and laser rangefinder. This sight is traversable, up to 45 degrees off of the main gun’s boresight in either direction, and is directly connected to the digital fire control computer. This sight is capable of 1x, 5x, and 15x zoom levels. A secondary 8x viewing telescope is aligned with the gun in case the gunner’s primary sight is damaged or otherwise rendered ineffective.

The commander’s station has access to an independent, rotating day/thermal sight with an integrated laser rangefinder. This sight has a 2-10x variable zoom option across both its daytime and thermal imaging channels. The commander also had access to a ring of periscopes surrounding the commander’s hatch for all-around visibility.

Both the commander and gunner have access to and dual controls over both optics. Both optics are also integrated into the fire control computer, allowing stored data from either. The shared capabilities of both of these systems allow for the commander to search for and designate additional targets for destruction even while the gunner tracks and engages previously designated targets. The integration of both sights into the fire control computer allows for the turret to be automatically rotated between marked targets as they are destroyed, with the gun being laid in by the data from the commander’s independent sight. This facilitates much more rapid engagement of multiple targets compared to previous vehicles.

The driver is equipped with a wide-angle day/night optic to facilitate night driving.

Operational History

Variants

- PaVå-33 - Original production variant, produced 1986-1990

- PaVå-33E1 - New radio with improved counter-ECM capabilities. Addition of a radio position and reporting system. Replacement of all night vision optics with third generation night vision devices. Produced 1990-1994.

- PaVå-33E2 - Introduction of the Rustningsforbedringspakke (RFS) armor enhancement package, using improved composite composition and depleted uranium inserts. Conferred a weight increase of approximately 4t compared to the original combat armor package. Option to replace commander’s remote machine gun with a InMg-74. Produced 1997-2007. All preceding vehicles would be upgraded to this standard by 2007, or converted into other specialized variants.

- PaVå-33E3 - Modernization of fire control systems, including improved thermal sights and a new ballistic computer. Addition of fittings for an FjT-1 remote weapon station. Produced 2008-present.

- PaLv-33 - Self-propelled anti-aircraft vehicle equipped with search and track RADAR and two 35mm autocannons mounted on a new turret.

- PaIn-33 - Armored Engineering vehicle, with a modular equipment load. Capable for use in mine and obstacle clearing, tracklaying, bridgelaying, and fortification construction.

- PaGj-33 - Armored recovery vehicle.