T80125

| T80125 | |

|---|---|

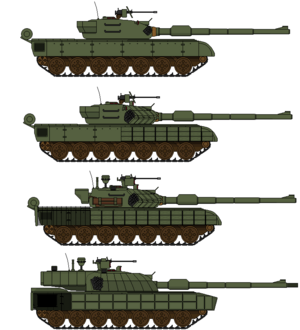

Base line model T80125 and its variants | |

| Type | Main Battle Tank |

| Place of origin | |

| Service history | |

| In service | 1980 - present |

| Used by | Tarsas |

| Production history | |

| Designer | Alderia-Anacom Armor Works |

| Designed | 1978-1980 |

| Manufacturer | Alderia-Anacom Armor Plant |

| Produced | 1980 - 2010 |

| Specifications | |

| Weight | 48 tonnes |

| Length | 9.72 m |

| length | 6.92 m |

| Width | 3.72 m |

| Height | 2.23 m |

| Crew | 3 |

| Armor | Steel and Composite armour |

Main armament | 12.5cm G04T L/53 smoothbore tank cannon |

Secondary armament | 2 x 7.62mm EA12 1 x 20mm autocannon 24 x 76mm smoke grenade launchers |

| Engine | Various 1000 hp |

| Power/weight | 22.2 hp/t |

| Suspension | Torsion Bar |

Operational range | 700 km (with fuel drums) |

| Speed | 65 km/h on-road 34.6 km/h off-road |

The T80125 is an Tarsan main battle tank that served from 1980 - 2004 as the prime main battle tank of the Imperial Legion. It was developed off the T82125 drivetrain prototype. The T80125 was the primary main battle tank in Tarsan units for over twenty years and had many variants and upgrades produced. It has been relegated to reserve units with the introduction of the T13125 Atlos. Numerous exporters also utilize the tank still today.

Development

The T80125 was developed in 1977 after a few pre production drivetrains from T82125 tanks were developed. Alderia-Anacom Armor Works co developed and built the drivetrain and develop a vehicle off of it. The joint design team began development in secrey in 1977. Pre production vehicles were released in early 1979. Testing revealed the vehicles as satisfactory. Production officially began in 1980 and the vehicles technically entered service in early 1981 after crew training.

Design

Interior

The crew of the tank was spread among the driver's compartment and the fighting compartment. The turret of the vehicle was relatively larger than the T82125 and the chassis is slightly lower but was wider. The driver was directly behind the primary armor angle in front of the turret. The Commander was located on the right side of the turret with a commanders hatch incorporating a 20mm autocannon which had to be operated manually at first but later received an upgrade for remote operation. The gunner was located on the right side of the turret next to the autoloader. A dual shell bustle autoloader was directly behind the main gun and can hold two shells before having to be manually fed shells by the gunner. The primary computer systems are located among the three stations based on who the information is relevant to. The interior, while slightly cramped, is still ergonomically designed to maximize available space.

Armour

The original T80125 possessed basic composite armour made from a combination of two plates of spaced rolled homogeneous armour with a heavy tungsten alloy and rubber plate fixed in between. The inner RHA plate was covered from the inside with a kevlar anti-spalling liner. Later versions included newly developed armor types that offered greater protection. The armor successively thickened over the years and began to be complimented by more soft kill options. The turret's armor was armoured steel laminate with tungsten and rubber layers with an extra plate of non-explosive reactive armor on the gun mantle for increased protection. Later generations of the tank included heavier more advanced armor. All versions are equipped with NBC protection and ventilation. Later versions also include hazard warning systems for detection NBC weapons.

Electronics

The tank did introduce several new systems to the military arsenal. This included analogue steering for the turret as opposed to manual. In terms of fire control, the T80125 had the improved ability to zoom in and out and replacing the old IR search lights with an IR night vision sight located diagonally left above the gun. In 1993, a laser range finder was added but the tank could also use coincidence rangefinding and GPS incorporated references for ranging targets. Later on, a gunner's independent sight and thermal vision mode for both the GIS and GPS was introduced. Later models included a module to connect to the Tarsan battle net communication network and more powerful computer suites. Early 21st century models received friend/foe identification computers and damage control devices.

Soft and Hard-kill Countermeasures

The first line of models incorporated a rack of 9 smoke grenade launchers on both sides of the turret giving them an 18 in total. Later variants increased this to 12 (24 in total) on both sides when the launchers had to be relocated to fit the forward ERA tiles. The smoke grenades produce a think smoke that hides the tank and surrounding area visually. The heat smoke gives off an infra-red signature which hides the tanks own and can disrupt lasers and reflect radar. Later models introduced a jamming system using a strong light that mimics the reference signal of wire and radio guided anti-tank missiles. This lights were mounted on the front of the tank beside the gun. The lights could be turned toggled via switch inside the tank.

Models from 1995 onward incorporated the KiteShield active protection system, which was designed to intercept anti-tank missiles and rocket propelled grenades. The system used a single Doppler-pulse radar mounted on the top of the turret to find, track and intercept incoming projectiles. Once it classed an incoming target as a threat, it would send a command to any significant rotating intercept-modules that sit on the sides of the vehicle. These would fire a blast of metal pellets at the incoming missiles or RPG which were able to disable the fire mechanism or destroy the projectile. It had a very small kill zone so as not to endanger personnel near the vehicle. The system could engage multiple-threats from different directions. In addition, the radar also added a direction warning system to the crew, which provided both warning of an imminent attack and the option to retaliate.

Armament

The main armament of the T80125 was the 12.5cm G02T L/43 smoothbore tank cannon manufactured by Anacom Industries. It was capable of effectively engaging and destroying any tank fielded when it came out in 1978. The effective range using APFSDS extendws to a little over 2km but penetration lessened over greater and greater distances. Using an HE-frag shell, it could reach distances beyond 12km at max elevation. The the recommended effective range was 4km with ordinary shells. ATGM capability was added to the vehicle in 1983 with a main gun upgrade. The gun had a velocity of 1900 to 2000m/s and the tank could carry 45 rounds in total. The loader had two modes, the gunner selected the type of round manually or sets it to sequence where it automatically kept loading the type of round the loader selected. When the weapon fired, the empty charge case ejected into a holder which was in turn discarded automatically by a separate mechanism during the loading cycle. The gun had a bore extractor to remove any poisonous fumes. Later series added a muzzle-drop compensator to improve accuracy on the move.

Variants

- T80125-M1 - Initial production model ordered in 1980. Sported the G02T 125mm smoothbore main gun. This was the only variant with a right mounted searchlight. It was produced at the Alderia-Anacom Armour Plant in Delphius until 1982 when production was switched over to the Mark 2.

- T80125-M1E - Export version of the M1 released in 1981. The model had decreased armor, downgraded internal systems, and additional cost saving measures.

- T80125-M2 - 1982 upgrade with a gas turbine engine and a newly designed thermal sighting system. Upgrades to the gun stabilization and the relocation of the searchlight to the right side rounded out the Mark 2.

- T80ARV - Armored Recovery Vehicle produced in 1983 off of the Mark II chassis. Half of the production run was offered in gas turbine and half in diesel. Produced in small numbers right up to the turn of the century.

- T80EV - Engineering vehicle that entered production in 1984. Half of all produced vehicles were equipped with a heavy bucket scoop and the other half with a bulldozer blade and crane.

- T80125-M3 - Introduced in 1985 as the primary production upgrade. Included Explosive Reactive Armor and a new autoloader system for firing ATGMs. Featured the new G03T 125mm main gun over the older G02T. The front armor angle was changed to 30 degrees for increased shot deflection.

- T80125-M3E - Export variant featuring Mark 2 pre upgrade systems but retaining the upgraded gun. Offered with a 1,200 horsepower diesel engine instead of a gas turbine.

- T80ABL - Entered production in 1986 as an armored bridge layer based on the T80125 chassis. Capable of deploying a twenty meter bridge.

- T80125-M4 - Introduced in 1988 as an extensive modernization of the T80125. It included a modified turret design, increased armor, and a modified suspension system. A more powerful 1600 horsepower gas turbine increased the top speed slightly. Plastic armor track skirts covered the upper part of the suspension with separate panels protecting the sides of the fuel and stowage panniers instead of the flipper type armor panels used in older variants. The turret front and top were heavily reinforced with composite armor and provisions for mounting reactive armor were added. An electronic fire control system, additional smoke grenade launchers, and a new optical sight were added.

- T80125-M5 - 1993 upgrade featuring the newly redesigned FVJS81 fire control system and a better gunsight system featuring thermal, night vision, and a laser range finder. A series of composite panels to reduce heat signature were placed around the front of the vehicle. The turret was further upgraded with different shot deflection angles and thicker armor. The turret front and top were heavily reinforced with composite armor. Appliqué armor was applied to the front of the hull. Laser-guided antitank missile capability was added as well as the new G03TB main gun. Additional mounts for more ERA bricks were added around the vehicle.

- T80125-M5E - Export variant with Mark 4 era systems though retaining the new gun and armor upgrades from the Mark 4.

- T80125-M6 - Released in 1994 as the military was looking to cut operations costs per vehicle. The gas turbine was removed for a diesel engine producing 1800 horsepower. Featured additional weight saving, lighter aluminum materials on the drive train.

- T80125-M7 - A version of the vehicle released in 1998. Featured A newly shaped turret with an ammunition stowage compartment in the rear that allowed for additional rounds to be carried. The new G04T 125mm smoothbore gun replaced the older G03TB. A highly advanced computerized fire control system that took over and integrated many functions of previous generation systems was installed. Additional armor was placed on the forward slope and frontal turret of the vehicle. A redesigned revolver autoloader and ballistics reference computer round out the upgrades.

- T80125-M7E - Export variant of the Mark 7 aimed at attracting Middle Eastern customers. Exported to

- T80125-M8 - The Mark 8 was the final military production variant introduced in 2002 before production was halted. The frontal arc was sloped slightly more to 40 degrees, creating additional room for the driver. An updated fully modern fire control system that combined the full functions of the vehicle's offensive capabilities was introduced. Turret armor was further reinforced and the engine was upgraded slightly to increase efficiency and fuel savings. The variant was fully equipped with a newly introduced friend/foe identification system as well as a new damage management system.

- T80125-M9 - Comprehensive post production upgrade introduced by Alderia in 2010 featuring an entirely new fire control system. A more space conscientious autoloader system gives the crew a slight increase on available movement room inside the vehicle. A new triple layer armor scheme featuring rolled homogeneous steel, ceramics, and advanced composites along with a top layer of non-explosive reactive armor offers more protection. Modifications to the turret, including more armored angles and an increased height, provide more protection and movement room for the crew. The G04TB L/56 gun was introduced on this variant. The vehicle was solely slated for export but the Legion has shown interest in applying the armor and computer system upgrades to 320 vehicles still in service with main line divisions. Shown at the 2011 Marvius International Armaments Exposition to several export customers.

- T80135 - Newly released variant featuring a powerful new Aegis Core Master Processing Suite, which was developed off of the advanced avionics employed on the Me-550. Combining the entirety of the processing systems into one electronic brain, the ACMPS was developed to make the turret fully autonomous, which represents a significant upgrade for the older design. Further improvements to the armor with additional strengthening along the frontal slope as well as the new 13.5cm T135a L/52 tank gun will significantly improve the vehicle. The T80135 marks the first combat ready autonomous tank turret in Tarsan service with the T13125 Atlos expected to follow.

Foreign Variants

- Ov. 2000 - In 1991, the Nekorian Ministry of Defense determined that the Ov. 68 main battle tank, which had been in service with the Nekorian Army since 1968, was obsolete when compared to the majority of front-line tanks in service around the world. Even with upgrade packages being developed in the late 1970's resulting in the Ov. 68B, and again in the early 1980's bringing the tanks to the Ov. 68C standard by 1987, the tanks were still considered too lightly armored and woefully under gunned compared to contemporary vehicles.

- In 1993, the Ministry of Defense agreed to pay several million dollars for a further upgrade program to the Ov. 68, providing it with a modern 120 mm cannon produced by Archlebau Defensive Works. The program was suspend in 1995 when evidence of vote tampering within the Republican Council surface. During a series of hearings it was determined that members of the Ministry of Defense had been paid by several sitting councilors on both the Regional and Representative Council to publish and present false information regarding the Ov. 68's capability and statistical comparison to other vehicles of its kind. This information grossly overstated the tanks abilities in most fields, and also exaggerated the capabilities of the Archlebau Defensive Works TK-120/49 cannon. Archlebau Defensive Works denied knowledge of these exaggerations but was unable to produce original technical documents to be compared to altered samples. The Republican High Court level charges against several Councilors, employees with the Ministry of Defense, and Archlebau Defensive Works. The case against Archlebau Defensive Works was dropped due to lack of evidence, but the court found 7 of the 16 implicated Councilors guilty of falsifing evidence presented in government hearings, bribery and assorted other charges. all were stripped of their citizenship and forced to resign from office. In addition, the sitting Minister of Defense also resigned, though he was not convicted of any wrongdoing. The Republican Council voted to continue the upgrade project, though the number of tanks to be upgraded was reduced from 450 units to 180 total units, which would be assigned to two reserve armored brigades. The primary reason the program was allowed to continue was that over 100 of the vehicles had already been upgraded, ad could replace the less effective Ov 68Cs slated for reserve formations. In addition, all production of 105 mm munitions for the Ov. 68C's main cannon had been stopped and most of the rounds destroyed between 1992 and 1994. 120 mm ammunition production had begun , with over 30,000 rounds stockpiled by 1995.

- Following the conclusions of the High Courts inquest, the Ministry of Defense was authorized to examine foreign designs and attempt to select a replacement tank to replace the 270 Ov. 68C vehicles still in service. The Republican Council felt this was of imminent concern as ammunition production for these vehicles main cannon and been stopped, and would costly to resume. The Minestry of Defense approached Alderia-Anacom Armor Works in early 1997 to inquire about the possibility of acquiring new production T80125 vehicles, with a 120 mm cannon instead of the standard 125 mm main armament. Negotiations for 270 vehicles to be delivered by 2002 were concluded by the end of the year. The previously used Archlebau Defensive Works TK-120/49 cannon was considered for the vehicles main armament, but lingering doubts following the 1995 hearings saw the Republican Council veto that suggest, and opt for a 120 mm cannon designed by a Tarsan firm. A re-bored version of the 12.5cm G04T L/53 smoothbore tank cannon, the 12cm G04T L/53 was designed and ready by mid-1999.

- The first delivers of Ov. 2000 vehicles occurred in December of 1999, and all 270 vehicles were delivered on schedule.

- B80125 Leaper- Variant of the T80125-M1 produced by Bahktar after the break up of the Bahktro-Hellenic Empire in 1980. It was subsequently developed into seven additional variants. The vehicle maintained its 125mm gun which Bahktar subsequently developed into the M532 Phalanx 125mm gun. The B80125-M7 is considered to be on par with the T80125-M9.

Export Customers

In 1995, the Defense Ministry of Benaajab contacted Alderia-Anacom with a purchase order for T80125-M1 tanks being phased out of service. Roughly 110 M1 tanks had been produced between 1980 and 1982 when the superior M2 model phased the M1 out of production entirely. Legion High Command had initially ordered the M1 tanks to be placed in reserve but had opted to scrap them in 1996. The company negotiated the release and sale of all 110 units, which were delivered between 1996 and 1997 after undergoing refurbishment and replacement of worn components. The engines were rebuilt, suspension components replaced, and hulls repainted. The T80125-M1 is currently in service with Benajaab though they are being courted for an upgrade to M3 or M4 models.

Users

- Template:Country data Nekor

- Nekorian Army: 270 units in service

Benaajab

- Royal Benajaab Armed Forces: 110 units