Type-061N submarine

SN-3953 shown with armament options.

| |

| Class overview | |

|---|---|

| Name: | Type-061N nuclear attack submarine |

| Builders: |

list error: <br /> list (help) Dar-es-Salaam Navy Yard United Nigerian Lagos Steelworks Philosir Industries Dakar Yards Santos de Cuba Guantanamo Navy Yard |

| Operators: |

|

| Preceded by: |

list error: <br /> list (help) Type-054N Type-046N |

| Cost: | NSD$2.1 billion (FY2014) |

| In commission: | 7 June 2011 |

| Planned: | 250 |

| Building: | 32 |

| Completed: | 66 |

| Active: | 66 |

| General characteristics | |

| Class and type: | Type-061N nuclear attack submarine |

| Displacement: |

list error: <br /> list (help) 9,500 tonnes surfaced 11,875 tonnes submerged |

| Length: | 122.3 m (401 ft) |

| Beam: | 13.7 m (45 ft) |

| Draft: | 9.1 m (30 ft) |

| Propulsion: |

list error: <br /> list (help) 1 × IDOS Power Systems NCV4-S1 LCFR (240 MWt, 66 MWe) 1 × United Nigerian D-50 diesel-electric unit (10 MW) 2 × S7SN integrated motor-propulsor (56 MW) |

| Speed: |

list error: <br /> list (help) 39 knots maximum submerged 27 knots stealth submerged 20 knots surfaced |

| Range: | 50 year projected service life |

| Test depth: | Greater than 800 m (2,600 ft) |

| Complement: | 84 |

| Sensors and processing systems: |

list error: <br /> list (help)

PSN-1976 X-band radar PSN-1977 ESM receiver |

| Electronic warfare & decoys: |

list error: <br /> list (help) 12 × Expendable submarine acoustic decoy Mk. 41 Submarine Torpedo Defense System |

| Armament: |

list error: <br /> list (help) 8 × 660 mm torpedo tubes (Up to 50 stowed weapons) 10 × Multi-purpose mission tubes (8 dorsal, 2 ventral) 1 x CRR-352 35 mm recoilless autocannon (sail) 4 × SAI-774 Sayaka SRAAM |

The Type-061N is a nuclear attack submarine class in service with the Punic Navy. The class is designed for a variety of open-ocean and littoral missions, including patrol, delivery and support of special forces, and land attack. A member of the Type-06X series of submarines, the Type-061N is designed to replace the previous Type-046N, Type-046N Advanced, and Type-047N attack submarines as well as the Type-052N ballistic missile submarine, now in service as a guided missile platform. The Type-06X series introduces a number of significant improvements in submarine design and technology, with greater attention to cost control and reducing long-term maintenance and overhaul requirements.

Development work began in 2005 as part of the NP21 project. As a result, boats of the Type-061N class share a number of components and systems with their surface-based relatives, and most components with the Type-062N ballistic missile submarine. Construction of the first boat of the class, SN-3900, began in 2009 and the vessel was launched in late 2010, commissioning into service in 2011. A total of 250 boats have been initially programmed, with a decision expected in 2020 as to whether to continue procurement beyond the expected 2030 cutoff date or begin development on a successor class. Based on rated reactor life, it is possible the class may serve through 2070 if procured through 2030. An improved design is expected to enter production by 2022, with the production plan expected to sustain production through 2030.

History

Nuclear submarine design and development in Carthage proceeded rapidly from the 1950s through the early 1970s, leading from the initial testbed SN-1105 and early first-generation designs to the eventual development of the Type-045N, Type-046N, and Type-047N third-generation attack submarines and the Type-052N and Type-053N ballistic missile submarines. By 1975, the submarine force had reached a peak of 850 boats in active service, including diesel-electric submarines. The submarine force played a vital role in protecting Carthaginian interests and winning naval superiority in the Atlantic during the Northern War. However, the conclusion of the war led to a draw down in defense spending and limited procurement of further boats and the design of new classes. By 1981 the attack submarine force had contracted to some 725 boats, and no new design had been introduced since the Type-053N.

By 1981, the expectation that reactor lifetimes on the Type-045N would begin reaching their end in the 1990s prompted the development of the first new submarine design in nearly a decade. The proposed Type-048N was designed for the budgetary realities of the post-war era, and was to be a compact, economical design relying on efficient hydrodynamics and a high degree of automation to improve speed and keep costs under control. Compared to the larger members of the third-generation Type-04X series in the 7,000 tonne range, the Type-048N was much smaller in the range of 4,900 tonnes, but retained the same speed and armament as the Type-045N. The class was approved for construction in 1987, entering service as the last design of the third-generation of nuclear attack submarines in the Punic Navy.

In 1983, the Kataphrakt Project was begun in conjunction with the Inuk Navy to develop an advanced new submarine to replace the high-speed Type-47N and counter the increasing threat of European carrier groups. The class made use of significant advances in digital signal processing and control technology, as well as more advanced reactor designs to develop a vessel far quieter than its predecessors while maintaining nearly the same maximum speed as the Type-047N. The design also incorporated a large battery of VLS tubes designed for the Type-104 anti-ship missile for use against surface groups. Designated the Type-054N in Carthaginian service, the class was introduced in 1990 with the commissioning of SN-3501, but production was cancelled in 1994 after just 48 boats were produced due to unsustainably high costs per unit. In light of strong protest from the Navy and the growing obsolescence of the baseline Type-046N, an improved design dubbed the Type-046N Advanced was approved for production to maintain large-boat force levels.

Advanced Submarine Research program

Although the Type-046N Advanced incorporated a number of the technologies and features used in the Type-054N, hull and budgetary constraints limited the degree to which the Type-046N could be modernized. New boats were considered to be roughly ten times quieter than their predecessors, but developments in European submarine technology threatened the ability of Carthaginian submarines to remain competitive in the medium to long term. With the reactor lifetimes of the Type-47Ns reaching their limits by the end of the 1990s, the need for a clean-sheet submarine design prompted the Navy to begin funding the Advanced Submarine Research (ASR) program to investigate new technologies for future use.

The ASR program included funding for four test submersibles to evaluate construction techniques, alternative designs, and new technologies as well as the use of existing submarines as testbeds for new equipment. The four test submersibles (SX-M1 through SX-M4) were constructed with varying displacement ranging from 800 to 1,200 tonnes, testing new steel and titanium alloys as well as increases in the use of polymers for ship fittings and coatings as a means of reducing weight. SX-M1 through SX-M3 tested newer, deeper-diving pressure hull designs while SX-M4 tested a new exterior hull design that largely eliminated the sail in order to reduce hydrodynamic drag. Two new land-based reactor plants were developed as part of the program to examine new reactor designs, including the first lead-cooled fast reactor considered for naval use since the end of Type-047N production.

As a result of these tests, several new draft designs were proposed for consideration in the 2003-2004 time frame. These designs included both conventional and low-profile sails, as well as both PWR and LCFR powerplant designs with the expectation that only one of the proposals would be selected for full design work. Although tested, titanium hulls were rejected from further consideration due to cost and production difficulties in manufacturing sufficient quantities of high-grade titanium plates to meet the expected production schedule. Testing indicated that the development of newer, higher-yield steel alloys could provide acceptable performance and could be more readily supplied by existing industry at a lower cost.

NP21 program

In 2005, the ASR program was rolled into the umbrella of the NP21 program and tasked with developing a full design for production, based on the results of its research. The Type-06X family of submarines were planned to replace all submarines currently in service, including both diesel-electric and nuclear attack submarines as well as ballistic missile submarines. Requirements were similar to the ASR program, and included improved stealth and endurance as well as greater modularity for the installation of future systems and to extend the useful lifetime of the series. The new prototype submarine SN-3884 was authorized as an interim testbed, to be used alongside the data gathered from the Type-054N project. Unlike the ASR program test submersibles, SN-3884 was authorized as a full-scale, fully-equipped testbed to include a full combat suite.

Technologies from various programs including the previous Type-054N as well as new technologies developed for the ASR program were incorporated into SN-3884. The testbed was constructed of SBY115 steel, a new alloy with a much higher yield strength than the previous SBY100 used in the Type-054N and Type-046N Advanced requiring new manufacturing and working techniques. The X4-S1 reactor, derived from the land-based LCFR design used in the ASR program, was finally taken to sea aboard SN-3884 for full underway testing. Other boats involved in the testing program trialed components requiring smaller overhauls, including new noise-reducing coatings and new sensors.

Type-06X series

Experience from these tests was incorporated into the basic design first proposed in 2003, with the final design submitted for consideration in March 2008. Major differences from the earlier draft included significantly increased support for unmanned underwater vehicles, improved quieting measures, and a radically redesigned sail. The design was to be powered by a single LCFR NCV-S1, the production model of the X4-S1 reactor, and rated for a projected test depth greater than 800 meters (2,600 ft). Surfaced displacement was projected to be in the range of 9,500 tonnes, and maximum submerged speed was estimated to be above 35 knots in public disclosures. Armament was to be composed of eight torpedo tubes plus eight large-diameter multipurpose VLS tubes, replacing the specialized VLS tubes of the Type-054N series. The proposal was specifically designed for conversion into an SSBN variant via the insertion of additional missile compartments amidships.

By 2009, contracts had been approved for the first boats of the new series, beginning with the Type-060 diesel-electric SN-3601. The first boat of the Type-061N class, SN-3901, was laid down in May 2009 at the Dar-es-Salaam Navy Yard, and was launched in January 2011. Following shakedown cruises, the class was officially commissioned into service in October. Based on the Defense Authorization Act of 2014, current funding supports a projected force of 480 boats at the current rate of sixteen per year through 2040.

Production of Flight II boats began in 2014 with the laying down of SN-3960. Flight II boats are designed to reduce construction costs and times through simplification to a target of $2 billion per submarine, and incorporate newer electronics with plans for retrofitting onto Flight I boats when rotated for maintenance. The first Flight II boats are expected to enter service in 2016. Long-term plans for a more comprehensively improved Type-061N Advanced are projected to begin production in 2026.

Characteristics

The Type-061N hull is 122.3 meters (401 ft) in length and 13.7 meters (45 ft) in beam, for a total displacement of 9,500 tonnes surfaced and 11,875 tonnes submerged. This represents a significant increase in displacement over the previous generation of submarines in the 7,000-7,200 tonne range, but was deemed a necessary compromise to add desired features as well as reduce acoustic signature. The increased beam in particular allowed for the introduction of double-rafting of machinery as well as additional space to store longer towed sonar arrays for increased sensitivity. With a reduction in crew and an increase in available space, the Type-061N is the first Carthaginian nuclear submarine to end the process of hot bunking, allocating a rack for every crewmember in the six-bunk cabins. Given these changes, the Punic Navy has begun formally recruiting female submariners for both enlisted and officer positions.

Hull design

Externally, the Type-06X family is largely an evolution of previous designs. Like previous classes, it incorporates a double hull to improve hydrodynamics without impacting internal space arrangements. Great attention was focused on the bow and stern to improve hydrodynamic flow to reduce noise, improving the sensitivity of the bow sonar while underway and reducing the risk of detection. As part of this effort, all protrusions and hatches forward of the torpedo tubes were removed or relocated, delaying the transition from laminar flow to turbulent flow, while stern taper was relaxed in order to reduce turbulence around the stern. Most noticeably, the tall sail has been replaced with a rounded dome toward the bow of the vessel, containing a set of folding antennas, sensors, and periscopes to reduce hydrodynamic drag.

Beam was increased in order to bring the design closer to the mathematically ideal length-to-beam ratio for a submarine, compensating for steady growth in length over the last few decades. The increased beam also allows for the addition of a fifth deck and improved acoustic baffling for engine components, reducing the submarine's noise signature. The stronger SBY115 structural steel used in construction also allows for the reduction in pressure vessel weight needed for diving, and a reduced number of hull sections was specified to reduce construction time and cost. The bow is composed of lighter acoustically-transparent composites to protect the bow sonar array.

Internal arrangements were much different than previous models. Whereas previous designs had used a single integrated pressure hull housed within the outer hull, new boats with the exception of the Type-060 diesel boat adopted the multi-hull solution, separating the habitable volume, reactor, and drive system into individual units. This was mandated by increased operational depth requirements, which necessitated minimizing the volume of any individual pressure vessel and allowed for the separation of the reactor compartment thanks to major improvements in the reliability of nuclear powerplants. This arrangement also increased stowage space in the inter-hull void for additional equipment, including longer towed array sonar and more advanced hydrophones.

Powerplant and propulsion

Nuclear-powered classes in the Type-06X series (including the Type-061N) are powered by the IDOS Power Systems NCV-S1 lead-cooled fast reactor, producing 240 megawatts of thermal power. Although designed alongside the surface pressurized water reactors as part of the NCV4 family, the NCV4-S1 differs in that it uses more advanced variable-speed machinery and is designed to be self-cooling at low to moderate power levels via natural circulation, allowing the coolant pumps to be shut down entirely. The Type-06X series is the first class in Carthaginian service to use a lead-cooled fast reactor design, as previous classes used either a lead-bismuth reactor or more commonly, a pressurized water reactor.

Unlike previous designs, the NCV4-S1 is designed to operate on a single core throughout its expected lifetime, eliminating the need for re-coring. Although supplying roughly the same output as the Type-047N's NCV2-S3M lead-bismuth reactor, the NCV4-S1 is more compact and efficient, allowing more volume to be allocated toward other mission requirements while supplying a greater useful electrical output for onboard systems. The number of pumps and valves was minimized compared to previous designs to reduce sources of noise and pipes and cooling loops designed to minimize joints and bends to maximize natural circulation potential.

In addition to the reactor, each submarine also carries a 10 MW diesel-electric plant to supply emergency power in the event of reactor shutdown when traveling at snorkel depth or surfaced. Operation of the plant requires raising of the snorkel, but it can be used to rapidly ventilate the ship in the event of a fire or radiological accident, and provide basic maneuvering power to the propulsors. The current powerplant design, the United Nigerian D-50, is designed for rapid starting and immediate loads using an electric starter. A supplementary battery unit is also installed to bridge the gap between reactor shutdown and diesel start up in an emergency and provide supplementary power during rapid acceleration.

The Type-061N is propelled by a pair of S7SN integrated motor-propulsors with 3.5-meter (11 ft) propellers, attached directly to the aft hull. In addition to reductions in noise through the use of a shrouded propulsor, as a rim-driven propulsor the S7SN eliminates the need for a shaft arrangement, reducing flow disturbance and increasing flexibility of placement. Each propulsor is rated for 28 MW output, allowing the Type-061N to reach submerged speeds of up to 39 knots while remaining stealthy at speeds up to 27 knots. Due to the use of dual propulsors, the Type-061N does not incorporate the retractable emergency propeller used in previous designs.

The use of X-form stern planes reduces the ship's minimum operating depth to 20 meters (66 ft), allowing it to operate much closer to shore than previous designs. The bow planes are retractable for operation in icy conditions, and the sail is reinforced to allow surfacing through ice sheets in arctic operations.

Sensors and control

The Type-06X family are equipped with the ESS-997 integrated sonar suite, composed of separate bow, sail, side, chin, and towed arrays. The Type-06X family adopts the water-backed ESA-992 bow array as a replacement for the older Mk. 53 air-backed array, reducing construction and maintenance difficulty while improving sensitivity. The current transducer design for the ESA-992 is designed to last the life of the submarine, eliminating the need for mid-life replacement. Supplementing the bow array is the ESA-994 sail array, designed to provide high-frequency coverage to supplement the bow array's mid and low-frequency coverage as well as improve navigation accuracy under ice. As an improved replacement for the ESS-990 integrated sonar suite in older systems, the ESS-997 provides improved sensitivity in passive operation as well as improved active performance, including a greatly expanded beamforming capability and a broader detection band.

The EST-995 high-frequency chin array provides more accurate seafloor mapping for maneuvering as well as greater resolution against mines and other threats. Mounted along the flanks is the ESH-993AM1 fiber-optic array, which uses fiber-optic-wrapped mandrels to replace the previous-generation ceramic hydrophones. The Type-061N mounts three arrays along each flank, providing complete broadside coverage. The system eliminates the need for electronics and is entirely passive, reducing maintenance and manufacturing costs over legacy solutions. The EST-996 towed sonar array also incorporates fiber-optic elements, and is composed of a retractable 85-meter (279 ft) fat line and 800-meter (2,600 ft) thin line array, each attached to a 800-meter cable and released through the hull space between the propulsors. Both are variable-depth systems, able to be positioned above or below the submarine's own depth to search adjacent acoustic layers.

In addition to acoustic sensors, Type-06X submarines incorporate an array of sensors designed to measure ambient conditions, including temperature, salinity, density, radiation, conductivity, and turbulence. While officially intended to allow the submarine to monitor its surroundings, a number of publications have put forth the notion that these sensors may be used for non-acoustic detection of submarines via wake tracking. These sensors are placed in a variety of locations around the hull and on the sail for full coverage around the submarine.

For detection when surfaced or at periscope depth, the Type-06X series uses a pair of fully digital photonics masts in place of an optical periscope, incorporating visual and infrared spectrum cameras as well as limited antennae for data transmission and reception. Additional masts provide the PSN-1976 X-band radar for surface and aerial detection, as well as the PSN-1977 ESM receiver for passive detection of electronic signals. Due to the unique design of the sail, these masts are designed to fold horizontally in addition to their traditional telescoping capability.

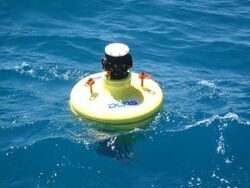

Communications while underway can be handled via tethered buoy, incorporating basic communications equipment as well as optical, infrared, and radar sensors. This allows the submarine to survey its immediate surface surroundings as well as communicate in conventional radio bands without exposing itself to detection at periscope depth. The tethered buoy may be used at depths up to 400 meters (1,300 ft). An additional trailing antenna located in the sail may be deployed to receive communications while at shallow depths.

Control is managed through the Advanced Submarine Combat System (ASCS), relying on lighter-weight fiber-optic cables for data transmission and multifunction displays for input. ASCS integrates sensor feeds from various sources and provides multi-target tracking capabilities for submarines, surface ships, and aircraft. Due to improved automation, manning requirements are reduced compared to legacy designs with the consolidation of several positions in the bridge, engineering, and weapons spaces.

Weapons

The Type-061N is armed with eight 660 mm (26 in) water-ram torpedo tubes, located in line with the sail and away from the bow in keeping with previous classes. The torpedo tubes are fed by a two-deck torpedo room accommodating up to 50 weapons and with an automated handling system. The primary munitions are the SST-720 and SST-721 heavyweight torpedoes and the SST-722 supercavitating torpedo. The torpedo tubes are also capable of firing other weapons, including cruise missiles such as the SST-725 and surface-to-air missiles. With the SST-725, the Type-061N has a maximum practical engagement range of approximately 130 kilometers (81 mi), allowing it to engage targets in adjacent convergence zones.

The Type-061N is also equipped with ten multi-purpose mission tubes, eight mounted dorsally behind the sail and a pair mounted ventrally. The mission tubes are identical in design to those used aboard the Type-062N ballistic missile submarine for maintenance and design commonality. Each can be used as a lockout and storage area for divers and their gear, but in normal use are equipped with mission support payloads. The dorsal tubes can each accommodate seven Mk. 18 VLS-compatible missiles, providing a maximum capacity of 56 weapons, while the ventral tubes are normally used to house a quartet of Long-Range Autonomous Minesweeper Vehicles, used to sweep a targeted area for possible mines without risking the submarine or other surface assets. The ventral tubes also commonly store a number of torpedo mines for deployment, as well as remote sonobuoys.

For protection from air attack, a four-cell VLS mounted in the sail holds SAI-774 Sayaka IR-guided missiles in watertight canisters. For use when submerged, the canisters are released and make their way to the surface, as with other submarine-launched missiles, before scanning their field of view to detect any potential targets. When surfaced, the missiles can be launched directly from their canisters in the sail. A 35 mm autocannon is also mounted in the sail for defense against light surface threats and as a means of delivering warning shots. Equipped with supercavitating ammunition, the cannon is capable of firing underwater, but cannot be used at speeds above 8 knots when submerged.

A standard weapons locker onboard maintains an inventory of pistols, rifles, shotguns, and space for man-portable anti-aircraft missile launchers used for force protection on the surface as well as potentially arming boarding parties in the event personnel cannot be supplied by a surface ship.

Special mission capability

The Type-061N is designed to support a variety of clandestine special missions, including commando insertion and extraction, the deployment of remotely operated vehicles (ROVs), support for navy divers, and possibly underwater cable splicing. Each Type-061N has berthing space for an additional 24 mission personnel with the ability to increase this to up to 40 personnel for shorter periods. 32 Type-061Ns are expected to be fitted with dry deck shelters for the commando support role to replace the 36 Type-046Ns currently used for these purposes.

Commando facilities include two lockout chambers at the at the bow and stern and storage space onboard for a limited number of diver propulsion vehicles. A new dry deck shelter was developed for the Type-06X series to account for the wider beam and to increase internal volume for a new generation of swimmer delivery vehicles (SDVs). The new module includes two shelters mounted over the rear lockout chamber, allowing two SDVs to be carried. The shelters are backwards compatible with the Type-15 SDV while adding sufficient space for use with the newer Type-16 SDV and Type-18 dry SDV. Without the dry deck shelter attached, the aft lockout hatch is also compatible with the Type-19 midget submarine, capable of delivering and retrieving commando teams at greater ranges than any of the current SDV inventory.

A permanent shelter for ROVs and UUVs is mounted to the rear of the sail on all members of the class, allowing for basic deployment and support of auxiliary craft. This shelter is too narrow for the use of current SDVs but smaller, more compact SDVs have been proposed for use with the shelter to expand the range of commando platforms. Both the dorsal and ventral mission tubes may be used to store additional equipment for special forces or diver teams.

Stealth and signature reduction

The Type-06X family incorporates advanced signature reduction technology for protection from both acoustic and electromagnetic detection. The increased hull diameter allows for moving equipment, especially engine components, to be double-rafted for improved sound absorption and the inner pressure hull to be largely decoupled from the outer hull. Decks are also isolated from each other and the hull where possible. The switch to electric drive eliminates the need for a propeller shaft while the electric propulsors are extremely quiet, removing additional sources of noise transmission. The use of a shrouded propulsor, flat sail, and X-form stern planes serves to eliminate blade rate and significantly reduce flow noise and turbulence. Designed for natural circulation and equipped with variable-speed machinery, the NCV4-S1 reactor is also much quieter than previous generations and can operate at up to 40% output without pumps active.

The outer hull is protected by a double layer of damping and anechoic material, composed of an inner layer designed to damp sounds emanating from the submarine itself, and a thicker outer layer designed to absorb active sonar pings and reduce the Type-061N's apparent target strength. The inner layer is approximately 30 mm (1.2 in) thick while the outer layer is approximately 100 mm (3.9 in) thick. Unlike previous installations and retrofits, the coating is applied through several spray-on layers, improving conformity to the hull shape, reducing drag noise from tile seams, and reducing the likelihood of coating loss at sea. The exception is the bow section, which is cast as a single piece with an even greater level of precision to cover the bow sonar array. Damping tile layers are also fitted to the internal pressure hull to further reduce sound transmission.

Design measures were also taken to reduce the possibility of non-acoustic detection. The basic design of the hull and sail are shaped to reduce vortex generation and thus minimize detectable wakes. The careful fairing of external protuberances and retractable bow planes are designed to significantly reduce the number of potential vortex generators. The arrangement of the stators in the shrouded propulsors is also designed to break up vortices generated by the propulsors themselves. An improved seawater mixing system for the waste heat exchanger was developed with the goal of reducing the submarine's thermal signature.

The Type-06X family incorporates active vibration damping, using a series of actuators to cancel and dampen detected noise and hull vibrations. This is the second generation of active vibration damping systems used by the Punic Navy, following the initial installation in the Type-054N and later in the Type-046N Advanced. These are controlled by a unified noise control system, which includes vibration sensors placed throughout the ship to detect and isolate sources of noise for reduction. The system also allows commanders to determine the effects on detectability based on their planned or desired speed.

Electronic systems are also shielded to reduce electromagnetic emissions and managed by a separate control system to maintain low-detectability. Where possible, composites and non-magnetic alloys are used to fabricate components and the outer hull is constructed of low magnetic steel to reduce susceptibility to magnetic anomaly detectors and other electromagnetic sensors. In addition to reducing susceptibility to magnetic detection, the increased use of polymers and composites is claimed to reduce surfaced displacement by an estimated 250 tonnes.

Crew and sustainment

The standard complement for a Type-061N boat is 84 officers and enlisted, in three shifts. This represents a reduction from the crew of 93 used in the previous Type-054N design, achieved through the increased use of automation and a decrease in the number of watchstanders per shift.

With the reduction in crew size and the increase in usable volume, crew are now housed in six-bunk cabins, allowing greater privacy and comfort during long deployments. Officers are accommodated in separate cabins, and the Type-06X series is the first Punic Navy submarine series to integrate mixed-gender crews with unisex facilities. Crew amenities include increased workout space for physical conditioning, increased storage for personal items, and movie facilities in the mess deck. Food storage and preparation areas were also improved. Additional accommodation for up to 24 mission personnel can be arranged for short term assignments.

In the event of emergency, a surfacing rescue capsule is located in the sail and can accommodate up to 90 personnel. This capsule also serves as the primary entry point to the sail and provides access to the dorsal UUV compartment. When carrying additional mission personnel, a second rescue capsule may be loaded into one of the multi-purpose mission tubes. Full-body Mk. 18 escape suits are also stowed for escape in shallower waters up to 180 meters (590 ft).

Replenishment of consumables is accomplished via palletized loads introduced via the rear lockout hatch. This hatch allows for faster replenishment than previous designs, although not as rapidly as the dedicated resupply hatches on the Type-062N. Improvements in reliability have reduced the number of lifetime overhauls from four to three, allowing for better readiness rates and a greater number of cruises throughout the boat's lifetime.