HP-130/2 Type 82

| HP-130/2 Type 82 | |

|---|---|

| Type | Naval gun |

| Place of origin | |

| Service history | |

| In service | 1982-present |

| Production history | |

| Manufacturer | Gyŏngsan Naval Artillery Plant |

| Produced | 1982-present |

| Specifications | |

| Weight | 54 tonnes (excluding ammunition) |

| Height | 3.65 meters deck to roof |

| Diameter | 3.5 meters (below-deck machinery) |

| Crew | 12 |

| Caliber | 130 mm |

| Barrels | 2 |

| Breech | sliding block |

| Elevation | -13° to +65° |

| Traverse | ±135° |

| Rate of fire | 30 rpm (per barrel, max) |

| Muzzle velocity | 950 m/s |

| Maximum firing range | 23 km |

| Feed system | 20 ready to fire rounds |

| Sights | fire-control radar electro-optical sight |

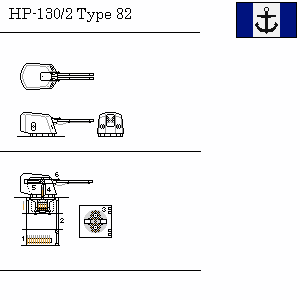

The HP-130/2 Type 82 (82식 해군 포탑 130/2, 82-sik Haegun Potab 130/2) is a twin-barrel dual-purpose 130mm naval turret developed in Menghe. More compact than the Letnian AK-130 but still bulkier than contemporary Sieuxerrian and Glasic weapons, the Type 82 is distinguished by a high rate of fire in 20-round bursts with a longer reload period in between. It is only used by the Chŏndong-class destroyers, having been replaced by the much lighter HP-130/1 turret on later warships.

History

The Menghean Ministry of National Defense is believed to have issued a requirement for a new naval gun turret in the mid-1970s, initially as part of an improvement plan for the Nunbora-class destroyers. The requirement called for a weapon with superior combat characteristics to the Nunboras' Letnian-designed SM-2-1 130mm turrets, including a faster rate of traverse, a longer effective anti-air range, and a higher rate of fire. While achieving these improvements, the weapon could not surpass the SM-2-1 in its mass or in its deck footprint, for easy integration onto future Nunbora subclasses.

Dayashinese reconnaissance satellites identified a test installation of a new twin turret in 1979, on an inland artillery trials range. GY Mudŏwi, the last Nunbora-class destroyer completed as a trials platform for new anti-ship missiles, was fitted with two Type 82 mounts in place of her original Type 70 (SM-2-1) turrets upon commissioning in early 1982, and the weapon was given a formal Type designation later that year.

The first planned application for the HP-130/2 Type 82 was the Chŏndong-class destroyers, which required heavy surface-to-surface gun armament on a compact hull. Early plans also called for the use of Type 82 turrets on a future guided missile cruiser class, which was later cancelled. During the 1990s, as Menghe pivoted to a smaller but more high-quality navy, the heavy Type 82 turret fell out of favor, replaced by a new single-barrel 130mm turret with a much lighter weight and greater reliability.

Characteristics

The automatic feed system on the HP-130/2 Type 82 consists of two 10-round rotating carousels mounted in the deck immediately below the turret. Unlike similar below-deck carousels on other 5-inch-range deck guns, these are mounted directly to the turret itself, rather than the hull structure. As the turret traverses, the entire carousel apparatus traverses with it.

Each carousel contains ten rounds in numbered spaces. The innermost slot on each carousel is located beneath one gun's trunnion, and contains a shell hoist capable of ramming rounds upward into a rotating tray, which then loads them into the gun breech. The carousels are fully mechanized and include a fuse-setting assembly for anti-aircraft shells. Rate of fire from the loaded carousel is 30 rounds per minute per gun, or a reloadng cycle of 2 seconds.

The below-turret drum arrangement allows the gun to fire at 30 rounds per minute per barrel (60 rounds per minute combined) for a period of 20 seconds, until each carousel is empty. The process of re-stocking the carousel with shells from the magazine is performed manually, and takes roughly 60 seconds, or 6 seconds per shell. The carousels can also be re-stocked while the gun is firing, for a sustained rate of fire of 10 rounds per minute per gun (20 rounds per minute combined).

As a result, the loading system is optimized to produce a "burst" of 20 rounds in 20 minutes, with a 60-second interval in between bursts. Menghean designers believed that this pattern was ideal for intercepting a wave of anti-ship missiles, engaging a hostile warship, or bombarding a land target, missions requiring a high rate of fire during a brief interval with time for reloading in between.

In sustained engagements, however, the gun is limited to a lower rate of fire, which declines when working in heavy seas or with a wounded or exhausted crew. The multiple manual hoist-to-hoist transfers require a large loading crew of 9 personnel (4 per hoist and one officer), in addition to two gun operators in the fire-control center and one backup gun operator in the turret. The attachment of the carousels to the turret also increased the total mass of the moving system, limiting traverse speed to 20 degrees per second.

Operation

The loading of the weapon follows the process below, with reference to the numbered diagram at right:

- Crew members manually load rounds from the below-deck magazine to the lower hoists.

- The lower hoists lift rounds to the below-turret compartment.

- Crew members manually transfer rounds from the lower hoists to the carousels.

- Rounds are automatically rammed upward into a loading tray.

- The loading tray pivots around the trunnion until the round is aligned with the breech. A rigid chain rams it in.

- Spent casings are ejected forward and outward from the centerline.

Ship classes using the weapon

The Chŏndong-class destroyers are the only completed warship class to use the HP-130/2 Type 82 as their main armament. The one-off destroyer Mudŏwi, a variant of the Nunbora-class completed as a trials ship, also carred two of these turrets for testing.

On land, a number of HP-130/2 Type 82 turrets have also been installed as permanent coastal defense batteries, particularly in the southwest. Several of these mounts are located around the coastal approaches to the Songsu-do Naval Base near Gyŏngsan. Some of these batteries place the upper carousel compartment in an above-ground steel or concrete building, while others are built with the entire below-deck assembly dug into the ground.