Lyasunov TRM-500: Difference between revisions

The ©rusader (talk | contribs) |

The ©rusader (talk | contribs) |

||

| Line 33: | Line 33: | ||

====Combustor==== | ====Combustor==== | ||

The TRM-500 features a double-annular combustor system, which differs from the generally-used single-annular by having two combustion zones around the ring. This design was chosen specifically to reduce the CO2 and NOx emissions of the engine. Fuel injection is regulated by a hydromechanical unit (HMU). Curently, a triple-annular combustion system is undergoing tests, and is expected to enter service with the new TRM-500M variant by 2024. | |||

====Compressor==== | ====Compressor==== | ||

Revision as of 14:47, 15 March 2020

| TRM-500 | |

|---|---|

| |

| Type | Geared turbofan |

| National origin | |

| Manufacturer | Lyasunov |

| First run | August 2001 |

| Major applications | DRJ-75 DRJ-105 Lyasunov L-42 |

| Program cost | $2.7 billion |

| Unit cost | $6.9 million |

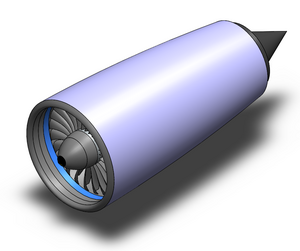

The Lyasunov TRM-500 (Dulebian: Лясунов Турбореактивный Мотор 500-ой серии, tr. Lyasunov Turbofan Engine 500 series) is a medium- to high-bypass (depending on variant) geared turbofan engine. The engines develop 57–93 kN (13,000–21,000 lbf) of thrust, and have variable bypass ratio depending on the variant. The engine family features three members, the TRM-500A, TRM-500B and the TRM-500S, a deforced variant with decreased bypass ratio and increased efficiency for smaller aircraft. Currently, the engines are used as a sole option for the Dulebian DRJ regional jet family, more accurately for DRJ-75 and DRJ-105 aircraft, and on Lyasunov's flying boat, Lyasunov L-42. In 2017, Lyasunov signed a contract with NACA, Dulebia's main aircraft consortium. According to it, Lyasunov remained in charge of combusting compartment and the compressor, control system (FADEC), transmissions (accessory gearbox, transfer gearbox), crank shaft maintenance and overall engine integration. The engine is remarkable for its reduced ground noise, which is 25% below the relative Erdaran Aircraft Regulation standard of 25 db.

The TRM-500 series provide relative efficiency compared to other small turbofan engines, and Lyasunov claims that on regional routes they're comparable to some turboprop engines in terms of efficiency and, most notably, CO2 emissions.

Design and development

Overview

The TRM-500 is a family of medium- to high-bypass ratio (most of the air accelerated by the fan bypasses the core of the engine and is exhausted out of the fan case) ranging from 2:1 to 5:1, and generating 57–93 kN (13,000–21,000 lbf) of thrust. While some details differ, the engines share a lot of components, with general unification of 87% between the types A and B, and 73% between them and type S. The engine features a two-shaft system, meaning that there are two rotating shafts, one high-pressure and one low-pressure, each powered by its separate turbine section. The fan and the low-pressure compressor vary on the different variants of the family.

Design

Combustor

The TRM-500 features a double-annular combustor system, which differs from the generally-used single-annular by having two combustion zones around the ring. This design was chosen specifically to reduce the CO2 and NOx emissions of the engine. Fuel injection is regulated by a hydromechanical unit (HMU). Curently, a triple-annular combustion system is undergoing tests, and is expected to enter service with the new TRM-500M variant by 2024.