Lyasunov TRM-500

| TRM-500 | |

|---|---|

| |

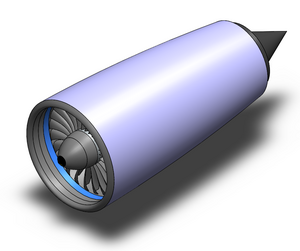

| CAD model of a TRM-500S | |

| Type | Geared turbofan |

| National origin | |

| Manufacturer | Lyasunov |

| First run | August 2001 |

| Major applications | DRJ-75 DRJ-105 Lyasunov L-42 |

| Program cost | $2.7 billion |

| Unit cost | $6.9 million |

The Lyasunov TRM-500 (Dulebian: Лясунов Турбореактивный Мотор 500-ой серии, tr. Lyasunov Turbofan Engine 500 series) is a medium- to high-bypass (depending on variant) geared turbofan engine. The engines develop 57–93 kN (13,000–21,000 lbf) of thrust, and have variable bypass ratio depending on the variant. The engine family features three members, the TRM-500A, TRM-500B and the TRM-500S, a deforced variant with decreased bypass ratio and increased efficiency for smaller aircraft. Currently, the engines are used as a sole option for the Dulebian DRJ regional jet family, more accurately for DRJ-75 and DRJ-105 aircraft, and on Lyasunov's flying boat, Lyasunov L-42. In 2017, Lyasunov signed a contract with NACA, Dulebia's main aircraft consortium. According to it, Lyasunov remained in charge of combusting compartment and the compressor, control system (FADEC), transmissions (accessory gearbox, transfer gearbox), crank shaft maintenance and overall engine integration. The engine is remarkable for its reduced ground noise, which is 25% below the relative Erdaran Aircraft Regulation standard of 25 db.

The TRM-500 series provide relative efficiency compared to other small turbofan engines, and Lyasunov claims that on regional routes they're comparable to some turboprop engines in terms of efficiency and, most notably, CO2 emissions.

Design and development

Overview

The TRM-500 is a family of medium- to high-bypass ratio (most of the air accelerated by the fan bypasses the core of the engine and is exhausted out of the fan case) ranging from 2:1 to 5:1, and generating 57–93 kN (13,000–21,000 lbf) of thrust. While some details differ, the engines share a lot of components, with general unification of 87% between the types A and B, and 73% between them and type S. The engine features a two-shaft system, meaning that there are two rotating shafts, one high-pressure and one low-pressure, each powered by its separate turbine section. The fan and the low-pressure compressor vary on the different variants of the family.

Design

Combustor

The TRM-500 features a double-annular combustor system, which differs from the generally-used single-annular by having two combustion zones around the ring. This design was chosen specifically to reduce the CO2 and NOx emissions of the engine. Fuel injection is regulated by a hydromechanical unit (HMU). Curently, a triple-annular combustion system is undergoing tests, and is expected to enter service with the new TRM-500M variant by 2024.

Compressor

The high-pressure compressor of the engine features seven stages in the TRM-500S variant, and nine stages on the other two variants. The compressor had a very compact span, which made the whole construction a lot lighter. A notable feature is that all bearings, oiling systems, and other accessory units are merged with the main fueling system, again decreasing the weight. Initially, a four stage variant was tested in 2005-2008, but failed to pass the Erdaran Aviation Regulation certification, and was later scrapped.

Exhaust

The TRM-500 features a mix-airflow exhausting system, which helps decrease emissions of the engine. The exhaust nozzle is of conic shape, featuring 19 separate exhaust pipes. Since 2017, Lyasunov together with NACA is testing chevrons for the exhaust nozzle. NACA and TsIAGI promise that chevrons will reduce jet noise by up to 1 decibel during take-off. They are expected to enter service on the TRM-500M variant in 2024

Fan

The TRM-500 fetures a single-stage, blisk fan with a four-stage low-pressure compressor. The fan has a diameter of 162 to 185 cm (64 to 73 in), deending on the variant of the engine. The fan features 32 blades on the initial -A version, 24 blades on the -B vesrion, and 16 blades on the -S version. 95% of the construction are made of composite materials, most notably Titanium. The fans are attached via dovetail join. This allows the replacement of separate blades, rather than the whole fan after an engine disassembly. This feature decreases maintenance time, especially after events like bird strikes, when only several blades are damaged at a time.

Engine reverse

The TRM-500 features several reverse thrust systems, tasked with slowing and stopping the aircraft after landing. The initial -A variant uses a cascade type of thrust reverser. This type of thrust reverse consists of sleeves that slide back to expose mesh-like cascades and blocker doors that block the bypass air flow. The blocked bypass air is forced through the cascades, reducing the thrust of the engine and slowing the aircraft down.

Types -B and -S use a pivoting-door type thrust reversers. They work by actuating a door that pivots down into the bypass duct, both blocking the bypass air and deflecting the flow outward, creating the reverse thrust.

Development

Operational history

Applications

Specifications

See also

- DRJ Series, Dulebian regional jet family, powered by Lyasunov motors

- NACA, Dulebian aircraft manufactuing consortium

- Skytrain, flag carrier of Dulebia