Nuclear power in Menghe: Difference between revisions

No edit summary |

No edit summary |

||

| Line 25: | Line 25: | ||

Both CNEC and NNPG are state-owned corporations with public utility mandates, meaning that the promotion of managerial staff is based on meeting productivity and safety targets set by the government, not on profit margins or shareholder value. CNEC and NNPG also collaborated during their early history. The Ro-900 and Ro-1000 reactors were both CNEC designs, but CNEC shared the patents with NNPG free of charge; the Ro-1200 reactor was a joint design between the two. Since 2015, however, the state-organized push to develop new Generation IV reactors has encouraged competition between the two giants, with each developing their own independent designs. In parallel, through the opening of new power plant locations, the two state-owned giants have spread beyond their original geographically separate regions, creating more competition around the country. | Both CNEC and NNPG are state-owned corporations with public utility mandates, meaning that the promotion of managerial staff is based on meeting productivity and safety targets set by the government, not on profit margins or shareholder value. CNEC and NNPG also collaborated during their early history. The Ro-900 and Ro-1000 reactors were both CNEC designs, but CNEC shared the patents with NNPG free of charge; the Ro-1200 reactor was a joint design between the two. Since 2015, however, the state-organized push to develop new Generation IV reactors has encouraged competition between the two giants, with each developing their own independent designs. In parallel, through the opening of new power plant locations, the two state-owned giants have spread beyond their original geographically separate regions, creating more competition around the country. | ||

The 2010s also saw the emergence of a number of independent nuclear power ventures, mostly in the research and development realm. | The 2010s also saw the emergence of a number of independent nuclear power ventures, mostly in the research and development realm. The Sunju Nuclear Research Institute, an offshoot of the prestigious Sunju Technical University, began independent research on a salt-cooled reactor with containment tubes in 2013, and in 2018 it formed a joint venture with the Ke | ||

==Regulatory structure== | ==Regulatory structure== | ||

| Line 102: | Line 102: | ||

From the standpoint of efficiency, the constant circulation and inspection of fuel pebbles means that the reactor can constantly trade out spent and fresh fuel elements. A conventional pressurized water reactor must power down completely before the fuel rods can be replaced, taking it off the grid for an extended period of time. Because each fuel particle is coated in a large amount of protective material, the physical volume of nuclear waste is also greater, though it contains the same amount of uranium. To counterbalance this problem, Menghean researchers are working on pebble bed reactors which can burn other fuels, including {{wp|reprocessed uranium}} and {{wp|thorium}}, but the production-model RSR-125 only uses enriched uranium dioxide. | From the standpoint of efficiency, the constant circulation and inspection of fuel pebbles means that the reactor can constantly trade out spent and fresh fuel elements. A conventional pressurized water reactor must power down completely before the fuel rods can be replaced, taking it off the grid for an extended period of time. Because each fuel particle is coated in a large amount of protective material, the physical volume of nuclear waste is also greater, though it contains the same amount of uranium. To counterbalance this problem, Menghean researchers are working on pebble bed reactors which can burn other fuels, including {{wp|reprocessed uranium}} and {{wp|thorium}}, but the production-model RSR-125 only uses enriched uranium dioxide. | ||

The Chŏllo Nuclear Power Corporation began construction of two RSR-125 reactors in 2013, in a new facility at the Hamhae Nuclear Plant near Chanam. In contrast to previous Menghean nuclear power plants, where each reactor is connected to one or more generator turbines, at the Hamhae facility both RSR-125s are hooked up to a single turbine which will generate 250 MWe of electricity. Up to a dozen more RSR-125 units could be installed at Hamhae, and more plants are tentatively planned; there is also ongoing design work on a larger multi-reactor complex, in which six pebble bed reactors are hooked up to a single 600 MWe turbine. New construction work has been postponed until after the two units at Hamhae have reached criticality, connected to the power grid, and undergone initial tests. | |||

===NR-600=== | ===NR-600=== | ||

[[File:Sodium-Cooled_Fast_Reactor_Schemata.svg|300px|thumb|right|Schematic of a pool-type sodium-cooled fast reactor, like the NR-600.]] | [[File:Sodium-Cooled_Fast_Reactor_Schemata.svg|300px|thumb|right|Schematic of a pool-type sodium-cooled fast reactor, like the NR-600.]] | ||

The NR-600 is | The NR-600 is the National Nuclear Power Group's flagship commercial-sized {{wp|Generation IV reactor}}. Two units are currently under construction at a new nuclear plant in Hyesan county. It is a pool-type {{wp|sodium-cooled fast reactor}}, using liquid sodium as coolant and in the primary loop, with steam in the secondary and tertiary loops. Construction on the two reactor units began in 2017 and 2018, and it is expected that both will be operational in 2024. | ||

The use of sodium as coolant offers a number of safety and efficiency advantages over a conventional pressurized water reactor. Sodium is a weak {{wp|neutron moderator}}, allowing the NR-600 to work as a {{wp|fast-neutron reactor}} while maintaining adequate cooling. Sodium also has a 785°C margin between its melting and boiling points, with the upper margin well above the operating temperature of the reactor, meaning that even a large surge in reactor temperature will not boil away the coolant and initiate a meltdown. This characteristic of sodium also means that the coolant does not have to be pressurized, and at higher heat levels, it exhibits greater {{wp|thermodynamic efficiency}} in converting reaction energy to electricity. | The use of sodium as coolant offers a number of safety and efficiency advantages over a conventional pressurized water reactor. Sodium is a weak {{wp|neutron moderator}}, allowing the NR-600 to work as a {{wp|fast-neutron reactor}} while maintaining adequate cooling. Sodium also has a 785°C margin between its melting and boiling points, with the upper margin well above the operating temperature of the reactor, meaning that even a large surge in reactor temperature will not boil away the coolant and initiate a meltdown. This characteristic of sodium also means that the coolant does not have to be pressurized, and at higher heat levels, it exhibits greater {{wp|thermodynamic efficiency}} in converting reaction energy to electricity. | ||

| Line 114: | Line 114: | ||

===SSR=== | ===SSR=== | ||

[[File:SSR_module_and_core_section.jpg|300px|thumb|right|A 3D model of an SSR reactor core, showing the passive cooling, fuel assembly, and fuel replacement airlock.]] | [[File:SSR_module_and_core_section.jpg|300px|thumb|right|A 3D model of an SSR reactor core, showing the passive cooling, fuel assembly, and fuel replacement airlock.]] | ||

In 2018, | In 2018, the Sunju Nuclear Research Institute signed an agreement with Kerenovian company Sůl-VKP engineering GmbH to construct a prototype commercial facility in Sunju municipality. This facility will use Sůl-VKP's patented {{wp|stable salt reactor}} concept, which combines a PWR-style {{wp|Nuclear_fuel#PWR_fuel|rod-type fuel arrangement}} with {{wp|Molten_salt_reactor|molten salt cooling}}. Enclosed fuel assemblies, each containing tubes filled with a mixture of molten salt and reprocessed plutonium fuel, are suspended in a pool of molten salts, which acts as a primary coolant. In contrast to other molten salt reactor designs, the fuel-containing rods are fully separate from the primary coolant, and fuel does not circulate around the reactor. | ||

Like other Generation IV reactors, the SSR design has a number of passive safety features which make a catastrophic failure less likely. Like the domestic NR-600 design, the salt coolant operates at roughly 1 {{wp|Atmosphere_(unit)|atmosphere}} of pressure and well below its boiling point, meaning that there is no risk of a boil-off or explosion. The salt-based coolant has a highly negative temperature coefficient, meaning that as the reactor heats up, the coolant slows it down more effectively, bringing it to a halt well before it reaches the salt's boiling point. Heat circulates naturally through the primary tank via convection, without the need for active pumps, and cools in heat exchanges which feed steam to a turbine in a separate building. If the secondary coolant loop experiences a total failure, convection-based air channels running underneath the stainless steel salt tank offer an entirely passive backup cooling mechanism. As a final active option, the operators can lower {{wp|boron}} control plates in between groups of fuel assemblies, slowing down the reaction manually. | Like other Generation IV reactors, the SSR design has a number of passive safety features which make a catastrophic failure less likely. Like the domestic NR-600 design, the salt coolant operates at roughly 1 {{wp|Atmosphere_(unit)|atmosphere}} of pressure and well below its boiling point, meaning that there is no risk of a boil-off or explosion. The salt-based coolant has a highly negative temperature coefficient, meaning that as the reactor heats up, the coolant slows it down more effectively, bringing it to a halt well before it reaches the salt's boiling point. Heat circulates naturally through the primary tank via convection, without the need for active pumps, and cools in heat exchanges which feed steam to a turbine in a separate building. If the secondary coolant loop experiences a total failure, convection-based air channels running underneath the stainless steel salt tank offer an entirely passive backup cooling mechanism. As a final active option, the operators can lower {{wp|boron}} control plates in between groups of fuel assemblies, slowing down the reaction manually. | ||

| Line 121: | Line 121: | ||

The commercial SSR facility planned for Sunju will have four reactor modules, each with a thermal output of 375 MW, in one coolant tank, for a total net electricity output of 400 MWe. Initial blueprints called for a concrete blast shelter over the reactor containment room, but this requirement was waived following the signing of the [[Sunju_Protocol_on_International_Conflict_and_Atomic_Energy|Sunju Protocol]]. Under the 2018 agreement, the joint enterprise would have two years to solve the remaining corrosion resistance challenges, three years to design the power plant facility, and three years to build the reactor, with the goal of bringing the reactor online before the end of 2026. This will allow for some time to run the reactor and gain working experience before the beginning of Menghe's Ninth New Five-Year Plan in 2029, which could include a lucrative Generation IV reactor construction initiative. Some Kerenovian engineers have expressed concerns that their Menghean counterparts are rushing the project to meet competition deadlines, particularly in regard to the expedited safety review process. | The commercial SSR facility planned for Sunju will have four reactor modules, each with a thermal output of 375 MW, in one coolant tank, for a total net electricity output of 400 MWe. Initial blueprints called for a concrete blast shelter over the reactor containment room, but this requirement was waived following the signing of the [[Sunju_Protocol_on_International_Conflict_and_Atomic_Energy|Sunju Protocol]]. Under the 2018 agreement, the joint enterprise would have two years to solve the remaining corrosion resistance challenges, three years to design the power plant facility, and three years to build the reactor, with the goal of bringing the reactor online before the end of 2026. This will allow for some time to run the reactor and gain working experience before the beginning of Menghe's Ninth New Five-Year Plan in 2029, which could include a lucrative Generation IV reactor construction initiative. Some Kerenovian engineers have expressed concerns that their Menghean counterparts are rushing the project to meet competition deadlines, particularly in regard to the expedited safety review process. | ||

==List of operational reactors== | ==List of operational reactors== | ||

Revision as of 02:28, 7 January 2020

This article is incomplete because it is pending further input from participants, or it is a work-in-progress by one author. Please comment on this article's talk page to share your input, comments and questions. Note: To contribute to this article, you may need to seek help from the author(s) of this page. |

History

In 1968, four years after the end of the Menghean War of Liberation, the government of the Democratic People's Republic of Menghe established the state-owned Menghean Nuclear Power Corporation (MNPC), which was tasked with surveying the country's territory for possible uranium deposits, constructing uranium enrichment facilities, and developing a domestic nuclear reactor.

General-Secretary Sim Jin-hwan was a major supporter of nuclear power for peaceful purposes, and under his leadership the MNPC increased its research and development efforts. The country secured permission to import a 4-Megawatt research reactor from Letnia in 1972, and brought it online in 1976. In 1978, the country began work on a domestic research reactor, which came online in 1983. Neither of these reactors were hooked up to the national power grid; their main purpose was to build domestic experience with reactor design, and to produce radioactive isotopes for Menghe's nuclear weapons program.

In 1982, agents of the Menghean government covertly opened back-channel negotiations with Ostland, whose military was rumored to be seeking data on nuclear weapons development to oppose the threat from Sebrenskiya. The two sides reached a secret agreement under which Menghe would share a steady stream of data from its nuclear weapons program, which was still a tightly kept secret at the time. In return, Ostland would export two nuclear reactors to Menghe, and share information relating to civilian nuclear power plant design. Construction of the first reactor, a 600-MWe Generation II PWR at Byŏkdong County in Anchŏn, began in 1983, and its twin began construction the following year. Following the November 4, 1984 nuclear test at Naran Gaja, the international community placed Menghe under an embargo for its violation of the STAPNA agreement, stalling construction work at both reactors. Even after Ostish engineers had left Menghe, however, the two countries continued to secretly trade test data for civilian nuclear blueprints in 1985 through 1987, allowing work on the Byŏkdong facility to continue at a reduced pace.

Following the Decembrist Revolution, Choe Sŭng-min's government ordered engineering teams to resume work on the Anchŏn plant, which was linked to the civilian power grid in 1992. Construction also began on civilian nuclear plants near Sunju and Yŏng'an, as part of a twenty-year plan to bring one civilian reactor online each year. This program focused on placing new nuclear power facilities on the Chŏllo plain and Meng river basin, which were far from coal-producing areas but were experiencing rapid economic growth.

Accelerated construction schedules and the rapid transition from experimental reactors to civilian power stations led to serious safety issues in Menghe's first set of Generation II reactors. Following the Chimgu nuclear accident in 2003, the General-Directorate for Energy shut down all operational reactors and instituted a temporary freeze on all new construction so that inspectors could review the causes of the Chimgu accident and draw up a list of safety corrections.

Construction resumed in 2006, after the report was finished, and retrofits of existing reactors began in the same year. During the temporary shutdown, coal power had filled the vacuum created by Menghe's ballooning energy needs, contributing to serious air pollution issues in major cities. Despite higher public opposition to nuclear power, the Menghean Socialist Party doubled down on its commitment to expanding the nuclear sector, aiming for 30% of the country's electricity to come from nuclear plants by 2030. By the late 2010s, the country was beginning construction on five new reactors every year, with a planned rate of ten reactors per year in the 2020s.

During the initial building spree, security against attack was a major concern in reactor design. Nuclear power was in the highest demand along the southern coast, where local geographic conditions were not amenable to the construction of coal or hydroelectric plants for high-volume output, but this area was also very close to Altagracia and the Entente forces stationed there. A major diplomatic breakthrough came in March 2019, when representatives of Menghe's main nuclear and military powers gathered to sign the Sunju Protocol on International Conflict and Atomic Energy. After the agreement was finalized, the National Nuclear Safety Administration announced that new reactors built in the southern region would be held to the same structural standards used in the rest of the country, reducing construction costs and opening the way to a flood of new construction around Sunju and Insŏng.

Over the course of the 2010s, Menghe also emerged as a leading player in the effort to design new Generation IV reactors based on safer and more efficient technologies. An RSR-250 two-unit pebble bed reactor at the Hamhae Nuclear Plant is scheduled to come online in mid-2020, and a pair of NR-600 sodium-cooled fast reactors at Hyesan are halfway complete and should be finished by 2024. A four-module stable salt reactor in Sunju municipality, part of a joint project with Kerenevoi, is still in development but projected to begin construction in 2023 and begin operation in 2026. Several other designs are still at the conceptual stage.

Corporate structure

Following a 1998 reform of Menghe's electricity sector, electricity distribution is controlled by the Menghean National Grid Corporation, while electricity production is controlled by a collection of separate independent power producers. During the transition process, all of Menghe's nuclear facilities were handed over to the newly-created State Nuclear Energy Corporation (SNEC). This was a state-owned enterprise with a legally protected monopoly on nuclear power production. In the wake of the Chimgu nuclear accident, Menghean regulators concluded that the SNEC monopoly created too many opportunities for collusion with regulators, and split SNEC's holdings to form the Chŏllo Nuclear Energy Corporation (CNEC) and National Nuclear Power Group (NNPG).

Both CNEC and NNPG are state-owned corporations with public utility mandates, meaning that the promotion of managerial staff is based on meeting productivity and safety targets set by the government, not on profit margins or shareholder value. CNEC and NNPG also collaborated during their early history. The Ro-900 and Ro-1000 reactors were both CNEC designs, but CNEC shared the patents with NNPG free of charge; the Ro-1200 reactor was a joint design between the two. Since 2015, however, the state-organized push to develop new Generation IV reactors has encouraged competition between the two giants, with each developing their own independent designs. In parallel, through the opening of new power plant locations, the two state-owned giants have spread beyond their original geographically separate regions, creating more competition around the country.

The 2010s also saw the emergence of a number of independent nuclear power ventures, mostly in the research and development realm. The Sunju Nuclear Research Institute, an offshoot of the prestigious Sunju Technical University, began independent research on a salt-cooled reactor with containment tubes in 2013, and in 2018 it formed a joint venture with the Ke

Regulatory structure

Originally, nuclear power plants in Menghe were regulated by the National Office for Nuclear Safety, an organ of the Directorate for Nuclear Power within the General Directorate for Energy in the Ministry of Economic Development. In the aftermath of the Chimgu nuclear accident, the General-Directorate for Discipline Inspection within the Ministry of Internal Security conducted an investigation of the NONS and found evidence that its inspectors had accepted bribes from SNEC to speed up approvals and loosen regulatory standards. Based on the evidence, the national leadership concluded that these problems stemmed from the close relationship between the NONS and the Ministry of Economic Development, which pressured its employees to treat pro-growth policies as their main priority.

In 2003, while the investigation of the Chimgu accident was still underway, the National Assembly passed a law establishing an independent oversight body, the Menghean Nuclear Regulatory Agency. The MNRA is not part of a higher ministry-level body, but instead reports directly to the Supreme Council. It is also part of the Septentrion Nuclear Regulators' Association.

From the first year of its creation, the MNRA ordered an expanded investigation of the events that led to the failure of the Chimgu reactor, in order to compile a complete and honest list of the design flaws involved. During this time, construction on new reactors was frozen, and all existing nuclear plants suspended regular operations in order to submit to inspections. Some scholars consider this a turning point in Menghean nuclear safety, as the MNRA made a serious commitment to putting safety ahead of cost and showed a high willingness to uncover evidence of corner-cutting. The nuclear IPPs largely fell in line, renovating their plants and retraining their personnel in order to fall in line with state regulations. More recently, as construction of new reactors has again reached dizzying rates, some international observers have expressed concern that the MNRA may be putting schedules ahead of safety.

Reactor models

Menghe operates a large number of different reactor models, the result of its reliance on international assistance and its turbulent development program. Additionally, because of the multi-stage construction and contracting process, many individual nuclear power plants contain a combination of different reactor types, usually with pairs of matching reactors introduced two by two across different time periods.

Domestically built Menghean reactors are designated "Ro" (로 / 爐), short for "nuclear reactor" (Menghean: 원자로 / 原子爐, wŏnjaro. Where "Ro" is used alone, the reactor is a pressurized water reactor, with the exception of Ro-1 and Ro-2, which were experimental gas-cooled units. Later types add modifiers to the designation: NR-600, for example, is a sodium-cooled fast reactor (나트륨냉각고속원자로 / 나트륨冷却高速原子爐, Natryŭm Naenggak Gosok Wŏnjaro).

Ro-5

The Ro-5 was Menghe's first civilian nuclear reactor. It was a licensed version of an Ostish Gen-II PWR design, built using a combination of domestically manufactured and imported components. Two were built, both at the Byŏkdong Nuclear Power Plant in Anchŏn municipality, in the late 1980s. At full capacity, each reactor generated a net output of 640 MWe of electricity. Construction stalled during the economic crisis of the late 1980s, but resumed in the 1990s.

Ro-5G

The Ro-5G, with G denoting "improved" (개선 / 改善, Gaesŏn), is a Menghean domestic improvement of the Ro-5 reactor, designed during the late 1980s and early 1990s. Its development benefited heavily from blueprints and technical information illicitly transferred from Ostland during the late 1980s, but as Ostland's government publicly denies any involvement, Menghe claims the reactor as a domestic design. The first reactor began construction in 1994, and it started operation in 1999, before the first 900 MWe design.

Like the Ro-5, the Ro-5G is a Gen-II pressurized water reactor with three coolant loops: a primary loop running through the reactor core, a secondary loop linking the primary heat exchange to the turbine, and a tertiary loop using water outside the plant to cool the secondary loop. The original 1970s-vintage control room equipment was retained, and many of the supporting systems were simplified in a bid to reduce costs. Net power output was also increased to 660 MWe. Eight reactors of this type were ordered, but due to safety concerns following the Chimgu nuclear accident, one was cancelled before construction, one was cancelled mid-construction, and one was rendered inoperable by a partial meltdown. The two existing reactors also underwent major safety refits, and the three under construction were modified to meet higher standards. As of 2019, the five surviving reactors remain in operation, and plans to deactivate them have been postponed in order to help meet air quality targets.

CP1

In tandem with the development of the Ro-5G reactor, Menghe ordered four 900 MWe reactors from Sieuxerr as an alternative measure in case work on the Ro-5G did not go as planned. The CP1 model selected for construction included some improved safety features, such as an emergency pump system to spray tertiary-loop water into the containment building, and matched two reactors to a single control room. Net electricity output was 944 MWe per reactor.

All four CP1 reactors were built at the Wando-Changjang facility, which serves the southern city of Sunju. They began construction in 1992, 1995, 1997, and 1999, but the first unit did not link up to the power grid until 1999, after the first Ro-5G reactor was online. Two more reactors of the type were still on order in 2003, but Menghe froze the contract in 2003 to conduct a comprehensive nuclear safety review. The contract was cancelled permanently in 2005 due to the deterioration of Menghe-Sieuxerr relations. Cancellation of the contract also interfered in the supply of Sieuxerrian-made parts to the second two reactors, which resumed construction in 2006, forcing Menghe to substitute foreign-made and reverse-engineered components. As such, despite their official CP1 designation, Reactors 3 and 4 at Changjang were completed to a slightly different standard, and differ in their output levels. Reverse-engineering work on these reactors served as a bridge to the development of the Ro-900 reactor, which began construction in 2009.

ABWR

After the lifting of the moratorium on new reactor construction in 2006, Menghe could no longer rely on components supplied from Sieuxerr. Nor could it rely on future construction of the Ro-5G reactor, which the Menghean Nuclear Regulatory Agency had ruled as unsafe for future construction. This created a problem at CNEC's Yungju-Daegwan plant, where one Ro-5G resumed construction but the remaining three were cancelled.

The Chŏllo Nuclear Energy Corporation responded by turning to Dayashina, ordering two 1300-MWe ABWR reactors for a new power plant in Daegwan county. Construction began later that year, based on negotiations made the previous year. Though the ABWR came with a much higher price tag than the CP1, it also generated more electricity at peak capacity. More importantly, it came with a wide array of new safety features, including passive safety features designed to shut the reactor down automatically and greatly improved coolant pumps within the reactor pressure vessel. Menghe ordered two more ABWR reactors in 2008, bringing the total at the Daegwan plant to four.

Though it carried the highest hopes, the ABWR design proved to be something of a disappointment. Construction work ran into delays and cost overruns, particularly on the first reactor. Once operational, the ABWR reactors also suffered from poor reliability levels, as they often had to be taken off the grid for maintenance. From activation until 2018, the four ABWR reactors at Daegwan were off the grid 32% of the time, compared to 9% at the four CP1 reactors. As a result, subsequent Menghean Gen III reactor design opted for more reliable approaches.

HAL

To keep pace with CNEC's Dayashinese reactors, the National Nuclear Power Group ordered four more nuclear reactors from Hallia. Like the ABWR units, these were ordered in two groups of two, with construction beginning in 2006, 2007, 2008, and 2009. These were all Generation II+ reactors with a PWR design, though they incorporated more safety features than the Ro-5 and 5G, and had a higher power output. Two were built at the Chanam Onsŏng plant alongside its existing Ro-5G reactors, and two were built at the new Yŏnsa facility in Hwasŏng directly-controlled city.

V-412

The V-412 was Menghe's third foreign-designed reactor built during the late 2000s. It was an imported Sebrenskiyan design, based on the VVER-1000 water-water energetic reactor family developed in Letnia. Two reactors of this type were ordered, and ironically, both were built by NNPG at the Byŏkdong power station, alongside the Ro-5 reactors purchased from Ostland in return for covert support for its standoff against Sebrenskiya.

HUNTR

The HUNTR (Heavy-water Uranium Nuclear Transition Reactor) is a Themiclesian reactor design designed to use unenriched uranium and reprocessed nuclear waste. As its name suggests, it relies on heavy water as its reactor coolant and primary loop coolant, increasing its neutron economy to the point that it can run on fuels with a lower content of fissionable atoms. In place of a reactor pressure vessel, the reactor is contained inside a large, non-pressurized chamber known as a calandria, and fuel bundles are inserted through the sides of the chamber on a continuous basis, allowing for on-grid refueling.

CNEC initially purchased two HUNTR 6 reactors, each with a net electric output of 650 MWe, for construction at the new Anpo Puryŏng Nuclear Power Plant in 2008 and 2009. Initial plans called for a total of four to six HUNTR-6 reactors at the Puryŏng site, which would be devoted to recycling reprocessed nuclear fuel. Early operation of the plant, however, revealed considerable cost-efficiency problems: the facility itself went well over budget during construction, and operating costs also proved to be higher than expected. In 2016, CNEC scrapped plans for future HUNTR reactors and instead ordered two Ro-1200 PWRs in its expansion of the Puryŏng site.

Ro-900

The Ro-900 is an indigenous Menghean 900-MWe capacity reactor, developed over the course of the 2000s and first built in 2009. It uses a three-loop PWR design, but with active and passive safety features incorporated from the HAL and V-412. The Chŏllo Nuclear Energy Corporation, which developed the design, claims that the reactor is indigenous, but foreign intelligence reports suggest that the Ro-900 was reverse-engineered from the Sieuxerrian SL1 reactors CNEC operates at Changjang. The Ro-900 is officially classified as a Generation II+ reactor, with some improved safety features but not enough to qualify as a Generation III design.

Ro-1000

The Ro-1000 is an improved variant of the Ro-900, uprated to generate 1000 MWe of electricity in net output. It incorporates a number of design revisions in order to moderately reduce costs and construction times without compromising on safety. While some 30% of components in the Ro-900 were of disputed legal status, and possibly reverse-engineered from Sieuxerr without licensed permission, CNEC claims that the disputed parts in question were replaced with indigenous designs in the Ro-1000.

The first reactor of Ro-1000 type began construction at the Hyangchun-Gilsan plant in 2012, before the first Ro-900 reactor was complete, and linked up to the commercial power grid in 2018. From 2012 until early 2015, the Ro-1000 accounted for most Menghean reactor construction, but it has now been superseded by the Ro-1200, which uses a safer Generation III design and produces a higher level of output.

Ro-1200

Developed from experience with the Ro-900 and HAL, the Ro-1200 is Menghe's first domestically developed Generation III reactor. The product of a joint venture between CNEC and NNPG, its blueprints are freely shared between the two corporations. At a fundamental level, the Ro-1200 is a pressurized water reactor with three coolant loops, based on the same principle as the CP1 and Ro-5. Its Generation III status is a result of many incremental improvements in safety, efficiency, and redundancy, rather than any revolutionary changes in fuel cycle or operating principle. Consequently, the Ro-1200 is relatively cheap to construct and operate, and familiar to nuclear reactor operators trained on other reactor types, as it relies on proven technologies rather than new concepts.

The Menghean Nuclear Energy Corporation claims that the Ro-1200 uses 20% less uranium fuel per MWe of output than a CP1 reactor, and consequently produces 20% less waste. It has a 60-year design life, extendable to over 100 years with a partial overhaul, compared to 40 years extendable to 60 among Generation II reactors. The Ro-1200 has a thermal efficiency coefficient of 0.38, converting roughly 3,200 MWth of heat energy into roughly 1,200 MWe of electrical energy.

It is projected that Ro-1200 reactors will experience only 50 core damage events per 100 million reactor-years (a core damage frequency of 5.0 × 10-7), or one every 2 million reactor-years. This is 100 times less frequent than the figure for the average Casaterran reactor of the 1970s and 1980s (5.0 × 10-5). In the unlikely event that a reactor does experience a meltdown, a concrete channel under the reactor is designed to catch the corium and divert it to an underground containment chamber, where it spreads out into a sub-critical geometry with radiation shielding above and a thick concrete pad below.

Since 2015, the Ro-1200 has accounted for the vast majority of Menghean nuclear reactor construction, with an average of six reactors beginning construction every year. At this level of output, the design has achieved economies of scale in parts construction and retention of skilled labor, keeping projected construction times under 6 years. The first Ro-1200 reactor, at the Chŏnggi Nuclear Power Plant, is progressing slightly ahead of schedule and should be ready to connect to the power grid in early 2021.

Ongoing research projects

Over the course of the 2010s, Menghe has emerged as a leading player in the development of Generation IV reactors. Both state and private companies are competing to bring prototype reactors into the commercial grid demonstration stage, in preparation for a larger rollout in the future.

In order to expedite research work, in 2017 the Ministry of Economic Development formally announced the beginning of a ten-year competition period to develop new reactor designs ready for commercial operation. This would leave at least two years of assessment, testing, and review ahead of the Ninth New Five-Year Plan in 2029, which could involve a massive initiative to build new Generation IV reactors. The RSR-125, NR-600, and SSR have all emerged as contenders in this peaceful development race, which would bring a lucrative reward to the winner.

RSR-125

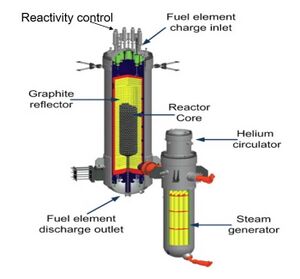

The RSR in this reactor type indicates Ransŏksang Wŏnjaro (란석상 원자로 / 卵石床原子爐), or pebble bed reactor. It is a high-temperature gas-cooled design, with a cylindrical reactor chamber hooked up to a turbine circulating helium gas. In place of fuel rods, the reactor chamber is filled with fuel spheres, or "pebbles," 60 millimeters in diameter. Each sphere is covered by a 5mm graphite coating, and contains a large number of spherical fuel particles, each 0.92mm in diameter. These particles contain an 0.5mm diameter uranium dioxide center surrounded by layers of protective buffer material, including silicon carbide, to prevent damage and moisture intrusion. In the course of regular operation, the pebbles drop out through a channel in the base of the reactor, where a special sensor measures their level of depletion and either returns them to the top of the pebble bed or sends them to spent fuel storage. This inspection process also allows broken or defective pebbles to be removed.

The pebble bed design has a number of important safety features. Because it naturally operates at 600°C, and with a strong negative reactivity feedback mechanism via Doppler broadening, even in the event of a catastrophic total failure of all mechanical and coolant equipment, the reactor would rise to a 900° "idle" temperature and stabilize there. Additionally, the coolant is inert helium rather than water, and it poses no risk of boiling into steam or reacting with fuel cladding. A final backup option allows the operators to manually release all fuel spheres from the reactor base into an underground holding chamber where they spread out to sub-critical geometry.

From the standpoint of efficiency, the constant circulation and inspection of fuel pebbles means that the reactor can constantly trade out spent and fresh fuel elements. A conventional pressurized water reactor must power down completely before the fuel rods can be replaced, taking it off the grid for an extended period of time. Because each fuel particle is coated in a large amount of protective material, the physical volume of nuclear waste is also greater, though it contains the same amount of uranium. To counterbalance this problem, Menghean researchers are working on pebble bed reactors which can burn other fuels, including reprocessed uranium and thorium, but the production-model RSR-125 only uses enriched uranium dioxide.

The Chŏllo Nuclear Power Corporation began construction of two RSR-125 reactors in 2013, in a new facility at the Hamhae Nuclear Plant near Chanam. In contrast to previous Menghean nuclear power plants, where each reactor is connected to one or more generator turbines, at the Hamhae facility both RSR-125s are hooked up to a single turbine which will generate 250 MWe of electricity. Up to a dozen more RSR-125 units could be installed at Hamhae, and more plants are tentatively planned; there is also ongoing design work on a larger multi-reactor complex, in which six pebble bed reactors are hooked up to a single 600 MWe turbine. New construction work has been postponed until after the two units at Hamhae have reached criticality, connected to the power grid, and undergone initial tests.

NR-600

The NR-600 is the National Nuclear Power Group's flagship commercial-sized Generation IV reactor. Two units are currently under construction at a new nuclear plant in Hyesan county. It is a pool-type sodium-cooled fast reactor, using liquid sodium as coolant and in the primary loop, with steam in the secondary and tertiary loops. Construction on the two reactor units began in 2017 and 2018, and it is expected that both will be operational in 2024.

The use of sodium as coolant offers a number of safety and efficiency advantages over a conventional pressurized water reactor. Sodium is a weak neutron moderator, allowing the NR-600 to work as a fast-neutron reactor while maintaining adequate cooling. Sodium also has a 785°C margin between its melting and boiling points, with the upper margin well above the operating temperature of the reactor, meaning that even a large surge in reactor temperature will not boil away the coolant and initiate a meltdown. This characteristic of sodium also means that the coolant does not have to be pressurized, and at higher heat levels, it exhibits greater thermodynamic efficiency in converting reaction energy to electricity.

Most safety concerns surrounding the NR-600 design focus on sodium's high reactivity, especially its reactivity with water. A water leak into a sodium channel, or a sodium leak into a wet environment, could generate a violent reaction producing heat, pressure, and combustible hydrogen gas, which was a major contributing factor to the Chimgu nuclear accident. Should a fire break out, it cannot be extinguished with water, which would intensify the reaction. The Hyesan nuclear facility is being built on a hilltop facing the sheltered Kimhae sea to reduce the flood and tsunami risk, but the current reactor design relies on water for the tertiary heat sink, and therefore it cannot be built too far inland.

SSR

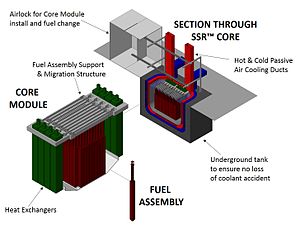

In 2018, the Sunju Nuclear Research Institute signed an agreement with Kerenovian company Sůl-VKP engineering GmbH to construct a prototype commercial facility in Sunju municipality. This facility will use Sůl-VKP's patented stable salt reactor concept, which combines a PWR-style rod-type fuel arrangement with molten salt cooling. Enclosed fuel assemblies, each containing tubes filled with a mixture of molten salt and reprocessed plutonium fuel, are suspended in a pool of molten salts, which acts as a primary coolant. In contrast to other molten salt reactor designs, the fuel-containing rods are fully separate from the primary coolant, and fuel does not circulate around the reactor.

Like other Generation IV reactors, the SSR design has a number of passive safety features which make a catastrophic failure less likely. Like the domestic NR-600 design, the salt coolant operates at roughly 1 atmosphere of pressure and well below its boiling point, meaning that there is no risk of a boil-off or explosion. The salt-based coolant has a highly negative temperature coefficient, meaning that as the reactor heats up, the coolant slows it down more effectively, bringing it to a halt well before it reaches the salt's boiling point. Heat circulates naturally through the primary tank via convection, without the need for active pumps, and cools in heat exchanges which feed steam to a turbine in a separate building. If the secondary coolant loop experiences a total failure, convection-based air channels running underneath the stainless steel salt tank offer an entirely passive backup cooling mechanism. As a final active option, the operators can lower boron control plates in between groups of fuel assemblies, slowing down the reaction manually.

The SSR design is also potentially cheaper and more efficient than other Gen III and Gen IV alternatives. As with the NR-600 and RSR-125, fuel assemblies can be removed, inspected, and replaced while the reactor is still in operation, without taking it off the grid for an extended period. Because it operates in a stationary pool at atmospheric pressure, there is no need for supporting machinery designed to withstand intense temperatures and pressures, and it is possible to build the reactor without an expensive containment chamber overhead. One of the most attractive features, reportedly decisive in Menghe's decision to fund a test site, is the fact that all reactor and plant components can be mass-produced at a separate facility and shipped by truck to the construction site, dramatically reducing costs if reactors are produced en masse.

The commercial SSR facility planned for Sunju will have four reactor modules, each with a thermal output of 375 MW, in one coolant tank, for a total net electricity output of 400 MWe. Initial blueprints called for a concrete blast shelter over the reactor containment room, but this requirement was waived following the signing of the Sunju Protocol. Under the 2018 agreement, the joint enterprise would have two years to solve the remaining corrosion resistance challenges, three years to design the power plant facility, and three years to build the reactor, with the goal of bringing the reactor online before the end of 2026. This will allow for some time to run the reactor and gain working experience before the beginning of Menghe's Ninth New Five-Year Plan in 2029, which could include a lucrative Generation IV reactor construction initiative. Some Kerenovian engineers have expressed concerns that their Menghean counterparts are rushing the project to meet competition deadlines, particularly in regard to the expedited safety review process.