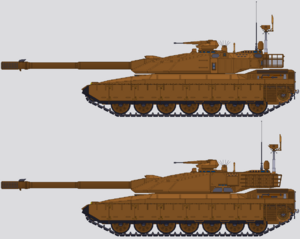

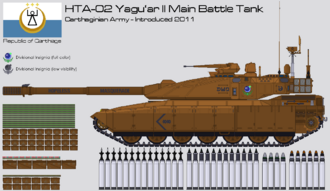

HTA-02 Jaguar II

| HTA-02 Jaguar II | |

|---|---|

HTA-02 Jaguar II in temperate camouflage. | |

| Type | Main battle tank |

| Place of origin | |

| Service history | |

| In service | 2011-present |

| Used by | |

| Production history | |

| Designer | Danel Group Armored Solutions Tingis-Lixus Mobility Systems |

| Designed | 2004-2010 |

| Manufacturer | Danel Group Armored Solutions Tingis-Lixus Mobility Systems |

| Unit cost | $16 million (FY2014) |

| Produced | 2011-present |

| No. built | 17,750 |

| Specifications | |

| Weight | 64.2 tonnes (71 short tons) |

| Length | 11.55 m (37.9 ft) (gun forward) 8.03 m (26.3 ft) (hull only) |

| Width | 3.80 m (12.5 ft) 3.85 m (12.6 ft) (w/skirts) |

| Height | 2.56 m (8.4 ft) (max) 2.06 m (6.8 ft) (min) |

| Crew | 3 (commander, gunner, driver) |

| Armor | Modular composite armor w/depleted uranium reinforcement Optional ERA and slat armor Rho Aias Active Protection System |

Main armament | 155 mm L/46 CBS-321 smoothbore gun |

Secondary armament | 1 × CRA-336 7 mm chain gun (coaxial) 1 × CRA-334 15.5 mm autocannon (RWS) 1 × IAG-127 30 mm automatic grenade launcher (RWS) |

| Engine | Danel Group DVR-2-12/1200E V-12 turbocharged diesel engine 1,200 kW (1,600 hp) |

| Power/weight | 24.9 kW/tonne (33.4 hp/tonne) |

| Transmission | North Iberian RAT-40-16B series hybrid drive (1,600 kW (2,100 hp)) |

| Suspension | Active in-arm hydropneumatic |

| Ground clearance | Variable 0.1-0.6 m (3.9-23.6 in) |

| Fuel capacity | 1,400 l (370 US gal) |

Operational range | 775 km (482 mi) |

| Speed | Road: 85 km/h (53 mph) Off road: 64 km/h (40 mph) |

Steering system | Electric |

The HTA-02 Jaguar II (Punic: 𐤓𐤀𐤅𐤂𐤉 "Yagu'ar"), originally classified as the HBT-11 Jaguar II is a third-generation main battle tank designed and fielded by the Republic of Carthage and the Gozen Shogunate. It is named for the original T-42 Jaguar tank, the first electric tank fielded by Carthage which entered service in 1943 and successfully served until the mid-1950s when it was replaced by the conventionally-powered T-54 Lion. A successor to the HTA-01 Rhinoceros, it is designed with improved firepower, armor, and mobility over its predecessor, although at 64 tonnes in its lightest configuration, it is significantly heavier. It is the first Carthaginian main battle tank to not be named after one of the Big Five game.

Development began in the mid-1990s and the tank was approved for initial introduction in 2011. Production continues as of 2017 and it is expected the Jaguar II will replace the Rhinoceros in most roles by 2018. It currently serves alongside the improved HTA-01DM, which incorporates some of the electronics improvements implemented in the Jaguar II. It is expected to remain the principal battle tank of Carthage through at least 2040 in upgraded forms.

History

Background

The HTA-02 Jaguar II was developed as a replacement for the existing MBT-74 Rhinoceros, which had performed with distinction in the Northern War. The Rhinoceros had outclassed the older 1960s-era European tanks, incorporating spaced armor, a more powerful gun, and superior mobility to even the lightly-built Leopard 1 and AMX-30, although the Rhinoceros was available in only limited numbers compared to the previous-generation MBT-64 Elephant. The only European tank capable of matching the MBT-74's firepower and protection was the British Chieftain, but the MBT-74 was faster and had a longer engagement range due to its use of gun-launched anti-tank missiles and improved sensors.

Using these capabilities, Carthaginian tanks regularly engaged European forces beyond the range of their retaliation, while the 120 mm cannon provided sufficient firepower for direct engagements. With these technologies, two Carthaginian divisions equipped with Rhinoceros and modernized MBT-64DM tanks successfully held off an eight-division European assault into Iberia and spearheaded the counterattack that secured the remainder of the peninsula. Loss ratios were comfortably in Carthaginian favor even after transitioning to the offensive. The Rhinoceros also performed well against Venetian M 61 tanks in Aegyptos and Ngola in Africa.

These decisive victories spurred the rapid development of European armor in the wake of the Northern War. The Leopard 2 finished trials and entered service in the German army mere months after the Treaty of Gades ended the war, while the British began deployment of the improved Challenger tank less than ten years later. The Byzantine Empire, still considered a potential foe by strategic forecasters, had already begun development of the Merkava-series, based on European technology assistance. Within the following two decades, the French developed the Leclerc, standardizing Europe's armies on 120 mm-armed tanks protected by composite armor and relying primarily on direct-fire kinetic munitions for anti-armor roles.

As the Second Pacific War began in the late 1980s, the European Federation deployed a joint division to assist their Mongolian allies in their attempt at reclaiming Japanese-held Manchuria. This was the first time the Rhinoceros engaged its new European counterparts, as Japanese armored divisions fielded the MBT-74 as their standard main battle tank. The results demonstrated a significant improvement in the capabilities of the new European tanks. Improvements in composite armor had severely reduced the efficacy of the gun-launched shaped charge anti-tank missiles then in service. The use of the more powerful 120 mm gun by the European tanks made them able to penetrate the MBT-74's armor at combat ranges. A crash program was initiated to improve the MBT-74 with better armor, a more powerful gun with more provisions for conventional APFSDS ammunition, and improved sensors, resulting in the MBT-74AM2 which entered production in 1992. A refit program for existing tank stockpiles was also initiated.

Concerns regarding the long-term suitability of this response remained, with weight growth a common complaint. The results of the AM1 modification had added some 6 tonnes to the Rhinoceros' weight, negatively impacting maneuverability. In 1995, the Next Generation Main Battle Tank program was initiated, to begin consideration of criteria for a clean-slate tank design. First conceived in 1998, the original NG-MBT program called for a tank in the 60-65 tonne range, with a slightly enlarged hull and a longer-barreled 120 mm gun. It would integrate components that had been added to the MBT-74AM2 and proposed for a future AM3, with a focus toward improving armor and mobility. New top-attack ATGMs would be used alongside improved APFSDS rounds to preserve lethality against enemy armored vehicles. A request for proposals was issued in late 1998 for a vehicle to these specifications, with a projected 18 month analysis period before down-selecting for prototype development.

In late 1999, however, the European Federation and the Venetian Commonwealth signed a memorandum of understanding to develop a new joint main battle tank, replacing the Leopard, Leclerc, Challenger, and M 79 series. Specifications for this new tank were kept secret, but by early 2002 evidence indicated that the new design would be armed with a 140 mm gun and be closer to the 70-75 tonne range, with provisions for additional armor. Complications with the NG-MBT program resulted in growing delays and there was an increasing fear that even if completed, the new design based on the original requirements would be inferior to the new joint European tank. In late 2002, the NG-MBT program was cancelled and new requirements were immediately evaluated for the replacement 21st Century Main Battle Tank program.

Development

By early 2003, a new set of requirements had been drawn up for the C21-MBT program. Weight class had been pushed to 65-70 tonnes, provisions for electronics improved, and the emphasis on armament increased. The new vehicle would also include sufficient overhead in terms of suspension and engine power to support add-on armor packages. Concerns about the cost of such improvements nearly scuttled the program, but increased political support for defense spending following the 2002 election cycle, the growing obsolescence of the Rhinoceros, reports regarding the progress of the European program, and heavy lobbying by defense contractors formerly committed to the NG-MBT program allowed the project to proceed as planned. A number of technologies and systems developed or proposed for the NG-MBT program were recycled to reduce costs and development time.

As a result of the Millennium Defense Review, a new organizational doctrine had been developed and a transition planned over the following decade to a new system of three combat brigade types, each with integrated artillery and support contingents for autonomous operations. Main battle tanks were to be limited to only to armored divisions, with light cavalry divisions fielding medium-weight vehicles including light tanks and infantry divisions fielding light wheeled vehicles and focusing on mobility.

Under the new doctrine, the role of armored brigades as heavy breakthrough and assault units in direct battle was emphasized, with rapid strategic mobility and especially aerial transportability requirements relaxed. With these constraints now of lesser import, greater focus was placed on a more capable vehicle, potentially at the expense of size, weight, and cost. In an attempt to control costs and reduce logistical complexity, the new tank was to serve as the base platform for other vehicles, including artillery and a heavy infantry fighting vehicle to equip the brigade with a common combat chassis.

| Armament | Protection | Mobility | Crew Comfort and Sustainment | Cost and Technology Risk |

|---|---|---|---|---|

|

|

|

|

|

Design work for certain subsystems to be standardized across the new vehicle fleet was subcontracted out in the early phase to several universities and private contractors. Armor development was carried out at the Ōarai Armor Research Facility in Ibaraki, Japan in conjunction with Japanese and Russian researchers, while the contract for powerplant development was given to the Danel Group's Automotive Diesel division, the manufacturer of the Rhinoceros' R-330 engine. Development of the fire control and electronics based on previous work for the NG-MBT program was contracted to the Electrocomputing Division of Santos de Cuba, which developed the Stele combat management system used in Carthaginian warships. A crowdsourcing campaign was run to develop the suspension design under the auspices of the Advanced Research Management Agency, won by a team from Carthage Imperial University in partnership with contractor Marina del Sur with an in-arm hydropneumatic design. Danel Group Armored Solutions served as the primary contractor, overseen by the Army Vehicle Research Center.

Throughout the development program a total of twelve prototype hulls and ten prototype turrets were constructed to test alternative arrangements and systems provided by subcontractors. Four hulls were equipped with torsion bar suspensions equipped with hydropneumatic dampers while the remaining eight used fully hydropneumatic suspensions. Different powerplant configurations were tested, including gas turbine and diesel engines in conventional and various hybrid arrangements. Of the ten prototype turrets, four were equipped with the lightweight 120 mm gun developed for the NG-MBT program while two were equipped with a prototype 140 mm gun and the last four with a new 155 mm gun. Different mounting, recoil, and sensor arrangements were tested between types. The combination of hull #8H using a diesel-electric hybrid powerpack with hydropneumatic suspension and Turret #6A mounting the 155 mm gun was selected as the basis for final development in 2006.

By 2008, the first engineering, manufacturing, and development prototype was produced at the Dakar Vehicle Integration Facility, with trials continuing through 2010. Four EMD prototypes were constructed for testing. The initial design was some three tonnes overweight, requiring a major improvement program aimed at reducing the projected weight as much as possible. This delay resulted in the European Liberator tank entering service first in mid-2009, with the Jaguar II finally being approved for low-rate initial production in early 2010 after weight targets had been met. The first tanks being assigned to active units in March 2011. Production shifted from initial low-rate production to full production in August 2011 following final evaluations of the vehicle by field units.

Service

The 3rd Armored Brigade Combat Team was the first active unit to convert to the Jaguar II, having trialed the tank for the past year. By the end of 2011, the rest of the 10th Armored Division had been converted and priority was placed on converting other rapid deployment corps units to the new standard. Concurrently, work was also begun in overhauling active MBT-74s to the 74DM standard to maintain combat readiness. Four factories were either converted or established to produce the Jaguar II with production established at 400 units per month and a separate assembly line was established in the Gozen Shogunate to meet Japanese production demands. The largest production facility is the Mbandaka Army Tank Plant, which produces 180 tanks per month. Production is currently expected to increase to 800 units per month in 2014 to equip all active divisions by the end of 2018, and all reserve divisions by 2022.

First deployments

Fielded by the Naval Infantry and the Army, the Jaguar II has been deployed to several international conflicts and crises. In field deployments, the Jaguar II has demonstrated acceptable strategic and tactical mobility, as well as improved reliability and detection capability. Minor cooling issues with the hybrid electric motor in certain climates were addressed through the introduction of a redesigned cooling unit capable of field installation.

Initial combat operations for the Jaguar II occurred in the Second Kilovosk Civil War, when the 22nd Armored "Thunder" Division of II Rapid Deployment Corps was dispatched to support the northern KNDF forces against the invading Kilovosk Liberation Army. Some 450 tanks in total were deployed between those on active service and those deployed as reserves and replacements and the Jaguar II demonstrated its superiority against the obsolescent T-62s and T-72s fielded by the KLA in large numbers. Twelve tanks were damaged or destroyed during the war, with four destroyed to prevent capture and the remaining eight recovered and returned to service. No combat fatalities were reported among Jaguar II crews, with only minor injuries incurred throughout the course of operations.

Development work is already underway for the HTA-02AM1, involving the trialing of new equipment including some components rejected from the baseline HTA-02 for technological immaturity at the time. The final HTA-02AM1 prototype is expected to be completed in 2017, with production estimated to begin around 2019.

Protection

Armor

Following the design of the Rhinoceros and most modern main battle tanks, the Jaguar II's frontal turret armor is suggested to be composed of a multi-layer composite matrix, incorporating a base layer of semi-hardened steel covered by a uranium dioxide metal matrix, silicon carbide tile matrix, layers of steel-sandwiched rubber special armor, a layer of non-explosive reactive armor, and an outer layer of steel-aluminum-rubber spaced armor. Included between the layers are absorption zones of lightweight aluminum foam and the interior of the tank is protected by a boronated polyethylene spall liner as a radiation shield. The most important changes from the previous armor arrangement is the addition of non-explosive reactive armor and an increased external slope, increasing the effectiveness of the ERA and contributing to the Jaguar II's improved protection versus the Rhinoceros. Other changes include the addition of triple-hardness steel, new titanium alloys, and a graphite matrix to improve the protective quality of the depleted uranium and ceramic layers.

The turret side arrays are believed to be much thinner, relying primarily on a series of special armor sandwich arrays to defeat autocannons and smaller HEAT charges. Protection against mines is provided by a sloped hull as well as a layer of titanium diboride tiles protected by spaced steel sheets and aluminum foam impact absorption layers. Roof protection is of similar design but omits sloping. The side skirts include a layer of composite fiber explosive reactive armor and a layer of conventional ceramic armor along the front half of the hull, providing improved protection to the fighting compartment. The remainder of the skirt is composed of thinner steel armor with slat armor over the drive sprocket.

The Jaguar II is also designed to mount Ōarai-type duplex explosive reactive tiles in the forward arc, further increasing protection particularly on the flanks and rear. Each tile is composed of a small copper shaped-charge liner above several layers of conventional semi-hard steel in an insensitive explosive matrix with a second, conventional ERA tile mounted below. The tiles are connected to the central combat system and are command detonated at the optimum stand-off distance with the resulting explosively-formed penetrator damaging the target regardless of type. Conventional ERA tiles without the EFP layer are used for roof protection and other areas where the firing of an EFP may be hazardous to exposed crew. These tiles add approximately 3,100 kg (6,800 lb) to the weight of the vehicle for a full protective suite.

In base configuration, the Jaguar II is resistant to tank-caliber APFSDS and HEAT rounds in the forward arc, with side protection against light rocket-propelled grenades and heavy autocannons. Modular armor packages can be mounted which provide additional protection, including against smaller-caliber tank rounds to the flanks and heavier HEAT warheads. This includes additional composite armor panels replacing the armor skirts to protect the hull, as well as ERA for the turret sides and roof to provide defense against top-attack munitions. Fully equipped, the Jaguar II's final weight exceeds 72 tonnes.

Camouflage and concealment

Originally painted flat desert tan or jungle green depending on theater, the current standard scheme is a coyote brown designed for performance in both desert and woodland conditions. The current standard Improved High-Durability Camouflage Coating also provides a reduced infrared and radar signature as well as resistance to chemical agents. Vehicles may occasionally be repainted with other designs for parade or special duty. Full-color insignia are painted over or covered with blank plates in the field. The Moonlight multi-spectral camouflage system, composed of fitted cloth-like material to further reduce radar and infrared signatures, is usually employed during combat deployments.

Two ten-barrel smoke grenade launchers provide concealment for the tank in the visible and infrared spectra, providing concealment from thermal imaging. Technology demonstrations have showcased the ability to be fitted with active infrared camouflage, allowing the vehicle to disguise its signature as that of another vehicle type or object, although no such kits are believed to be in service. Snap-on radar-absorbent panels may also be equipped in the field to reduce vulnerability to radar-guided weapons.

The thermal signature of the engine is masked by cooling the exhaust through the mixture of fresh air via the powerpack cooling system to lower emissions temperatures. The exhaust system is designed to reduce dust-scattering and track skirts are used to further reduce dust signatures while on the move. With a lighter and more compact diesel engine than previous designs, the Jaguar II is quieter than its predecessors and limited acoustic baffling in the engine compartment is designed to reduce noise emissions further.

Active protection system

The Jaguar II was designed from the outset to integrate an active protection system, and the Rho Aias APS can draw directly from the vehicle's primary sensors via a centralized control system. In addition to the vehicle's integrated suite of electro-optical and thermal imaging devices, the system includes a laser and radar warning receiver, control over the smoke dispensers, an infrared spotlight to disrupt IR-guided missiles, anti-radar smoke dispensers, and a dual-layer hardkill system composed of the VLS missile-based EAH-537 and the flank-mounted EAH-538 kinetic energy system for short-range interception.

The system provides protection against both long- and short-range missile and rocket attacks, as well as some protection against kinetic attacks depending on detection distance. The flank-mounted EAH-538 hardkill units provide rapid-reaction, high-capacity, short-range defense most useful in confined spaces via shaped charges, minimizing collateral damage. Supplementing this system, the VLS EAH-537 missiles provide an interception range of several hundred meters against stand-off top-attack munitions including guided missiles and overflight weapons such as STAFF.

Damage control

The Jaguar II is equipped with an automatic HFC-227a fire suppression system to extinguish internal conflagrations. Automated temperature and visual sensors in the tank can detect a fire in the fighting compartment within milliseconds and suppress the fire within seconds, while crew members have access to additional hand-held fire extinguishers. A second fire-suppression system is located in the engine compartment and can be controlled by the driver or commander. Onboard ammunition also conforms to insensitive munition standards, being resistant to detonation by enemy fire as well as sympathetic detonation from nearby rounds. Ammunition in the bustle is isolated from the fighting compartment and provided with blowout panels while rounds in the hull container are protected by the container itself and a rear deck blowout panel.

Seating arrangements for the crew are designed to improve blast resistance and energy attenuation, reducing the effects of kinetic shocks and blasts particularly from mines and improvised explosive devices. The driver is provided with a suspended seat which eliminates floor contact while both the gunner and commander are provided with seats attached to the walls of the turret basket with an additional protective layer on the turret basket floor. The seats significantly reduce the shocks transmitted to the crew and reduce g-force and spinal loads during blast events, preventing injury and allowing the crew to remain combat effective or escape the vehicle if immobilized.

Armament

Primary

CBS-321 smoothbore gun

Expanding on the gun-launched anti-tank missile concept developed in the MBT-74, the Jaguar II is armed with a 155 mm L/46 smoothbore gun designed to fire more capable missiles as well as more powerful armor-piercing ammunition. With HEAT penetration strongly related to charge diameter and a projected need for larger propellant charges for direct-fire ammunition, a larger cannon was determined to be necessary to meet projected firepower goals. Proposals for an electrothermal chemical gun were rejected in favor of the conventional Philosir-made CBS-321.

The gun barrel is composed of autofretted high-strength alloy steel with an explosively-deposited tantalum liner, sheathed with a tensioned carbon fiber overwrap and covered with a thermal shroud for protection from the elements. The use of a carbon fiber overwrap is intended to reduce weight without compromising strength and rigidity while the tantalum liner is designed to improve heat resistance to higher temperature propellants. As a result, expected barrel life is 1600 full charges, greater than the 1500 EFC rated for the T-17 gun in the MBT-74 using a chromium liner. The thermal shroud incorporates a thermocouple temperature sensor and a dynamically tuned damper near the muzzle brake to reduce barrel vibration. Due to the greatly increased impulse when firing, a slotted baffle muzzle brake is fitted to the barrel and recoil travel was increased from 280 mm (11 in) to 400 mm (16 in) to keep recoil forces manageable. As a result, gun depression is limited to -7° but is offset by the vehicle's ability to adjust its forward and rear ride height, allowing an effective depression of -15°.

The gun is fed using a chain autoloader and fired using a laser ignition system to improve safety and optimize burn rate. The autoloader stores 28 rounds in the bustle and an additional eight rounds are stored in the secondary magazine forward of the engine compartment. These rounds may be fed into the autoloader while out of combat or fed directly into the gun, although this process is slower than loading from the bustle loader. Both magazines are replenished through a rear hatch in the turret, where ammunition can be fed via hydraulic conveyor or manually, with secondary magazine ammunition being pushed through the bustle loader to the loading tray and lowered into place. Rounds are identified to the fire control computer using embedded RFID chips and identified visually by nose color.

The autoloader system holds a total of 36 rounds, normally allotted in Carthaginian service to 14 APFSDS-T, 12 advanced HEAT multipurpose rounds, 4 AATM-CE, and 6 AATM-KE.

- DSD-907 HEAT-AMP-T: The DSD-907 multi-purpose HEAT round is a tandem charge, programmable fuze munition designed for use against vehicles, helicopters, personnel, and fortifications. Designed with a depleted uranium liner and a larger fragmentation sleeve relative to previous models, the most significant performance improvement is the addition of the new smart fuze, which can be set to air burst, post-penetration, impact, and proximity detonation and which allows the DSD-907 to replace the previously separate canister, HEAT, and demolition rounds for a simpler ammunition load. Muzzle velocity is 1,400 m/s (4,600 ft/s) for an effective range of 3,000 m (3,300 yd).

- DIT-910 APFSDS-T: The DIT-910 is a 1,100 millimeters (43 in) jacketed depleted uranium penetrator designed for use against enemy tanks and other heavily armored vehicles. The round is believed to be composed of a depleted uranium core sheathed with a titanium jacket to improve rigidity and resistance to bending. Muzzle velocity is 1,675 m/s (5,500 ft/s) for an effective range of 4,500 m (4,900 yd).

- SGC-415 AATM-CE: The SGC-415 Advanced Autonomous Tank Munition-CE is a guided, tandem-charge HEAT weapon designed for medium to long-range engagements, including beyond-line-of-sight (BLOS) targets. The AATM-CE uses a dual-mode imaging infrared/semi-active laser seeker to enable fully autonomous engagement of targets beyond the tank's line of sight, while also allowing for man-in-the-loop guidance at BLOS ranges where the danger of collateral damage or friendly fire is too great for autonomous engagement.

- SGK-416 AATM-KE: The SGK-416 AATM-KE is a guided medium to long-range kinetic energy munition designed for use against main battle tanks and other heavily armored targets with extensive protection against HEAT munitions. While conceptually similar to the AATM-CE, the AATM-KE uses a depleted uranium penetrator for terminal effects and is guided by a dual-mode millimeter wave/semi-automatic laser seeker, enabling similar options for autonomous or man-in-the-loop guidance at ranges beyond 2,000 m (2,200 yd). Launch velocity is 1,200 m/s (3,900 ft/s) but impact velocity is 2,400 m/s (7,900 ft/s).

Secondary

The Jaguar II carries two secondary weapon mounts in normal service:

- One CRA-336 7 mm electrically-powered chain gun mounted coaxial to the main gun, provided with 6,600 rounds of ammunition. The coaxial gun is aimed and fired using the same computer system as the main gun and can serve as a spotting gun in the event of malfunctions with the electronic fire control systems.

- One CRA-334 15.5 mm electric chain gun in a remote weapon station on the left side of the turret roof. The CRA-334 is normally loaded with a mix of JHA-830 SLAP, JHI-831 HEIAP, and JHP-835 ball rounds in mixed belts to engage a range of targets. The CRA-334 was the first weapon in service to adopt polymer-cased telescoped ammunition, although widespread rollout of the type to replace previous conventional ammunition in other weapons is underway.

- One IAG-127 gas-powered 30 mm grenade machine gun attached to the same RWS as the chain gun. The IAG-127 is a dual-feed device normally armed with JGI-812 high explosive dual purpose and JGA-812 air bursting ammunition. The grenade launcher is intended for use primarily against light vehicles and infantry teams in cover or the open using air bursting rounds to defeat surface cover.

The IAG-127 and CRA-334 use the same FRC-354 low-profile remote weapon station, reducing the vehicle's effective height without sacrificing flexibility. The RWS includes a telescopic electro-optical and infrared sight for long-range all-weather engagement. In normal operations the commander controls the RWS while the gunner controls the coaxial weapon along with the main gun. The turret-mounted secondary weapons however can be set to automatically engage targets detected by the gunshot location system or those designated by any crewman.

Both weapons are capable of being loaded with non-lethal ammunition, although the gas-powered IAG-127 requires charges designed to produce enough gas to cycle the action unless a special adapter is installed. The externally-powered CRA-334 does not require modification to work with lower power non-lethal rounds.

Additional roof-mounted data and power ports are available concealed beneath protective covers to mount additional systems, including both armaments and sensors. Planned options include loudspeakers and potentially even a microwave-based non-lethal crowd dispersal system.

Fire control

The tank commander is provided with an independent panoramic sight providing both day and night channels for viewing. The day channel provides magnifications of up to 40× while the night channel provides magnifications of 28×, with an additional 5× digital zoom factor. The day channel is equipped with an optical channel and has a BSI CMOS image sensor for daylight and ICCD low-light vision. The night channel is equipped with a 1280×1024 LWIR thermal imaging system for passive detection and engagement of targets in obscured conditions. The sight is fully stabilized and equipped with a binocular eyepiece for greater comfort. With the onboard laser rangefinder, the commander may use his independent sight to aim and fire the main gun directly without handing off control to the gunner if required.

The gunner's primary sight is composed of a fixed array providing day and night channels. The gunner's sight uses most of the same magnification and vision systems as the commander's panoramic sight and is also stabilized in two axes, but uses a dual-band LWIR/MWIR FLIR instead of the commander's single-band LWIR FLIR for better target discrimination. The gunner is also provided with a low-light optical correlation rangefinder mounted above the gun mantlet. While equipped with a laser rangefinder, both the gunner and commander's sights also include stadiametric rangefinders as a backup for other systems. The gunner may also use the optics attached to the remote weapon station as an independent sight of his own when not managing an engagement, allowing the gunner to contribute to the vehicle's awareness. Using his own multifunction display it is also possible for the driver to operate the RWS although this is rare.

Fire control data are managed by the central EPU-592 combat management system, which coordinates input from awareness sensors including the Ka band radar, infrared, electro-optical, vibration, and microphones and makes this data available to all crew members and onboard systems as required. It also manages input from weapon-specific sensors including the laser rangefinders, crosswind sensor, cant sensor, muzzle reference system, boresight alignment data, temperature and atmospheric pressure data, and stored information on round types. In addition, a retractable sensor mast at the rear of the turret can be used to extend sensor range or to provide observation of targets from behind cover. The commander and gunner's stations are compatible with the Modular UAV Control Interface, allowing either crewmember to control and receive data from unmanned aerial vehicles.

The firing solution is continuously updated and projected onto both the gunner and commander's sights. Using the Jaguar II's additional sensors, firing solutions on up to two targets may be maintained simultaneously, monitored by the gunner and commander. A fire interrupter delays firing if a sudden and unpredictable movement occurs, preventing unexpected obstacles from impacting accuracy. With its autoloader and the integration of the turret drive into the combat management system, the combat system is capable of slewing and elevating the turret on its own, although it cannot fire without a command from a crewmember. The system is capable of locking and continuously tracking targets selected by the commander or gunner using a combination of the optics and rangefinders.

Jaguar IIs also carry a limited quantity of spotting rounds designed for use in the coaxial chain gun which are ballistically matched to the main gun to a range of 1,500 meters (4,900 ft) and can be manually loaded by the gunner if needed. The ground surveillance radar mounted on the retractable mast is capable of resolving pedestrian-sized targets out to 10 kilometers (6.2 mi) and tank-sized targets out to 24 kilometers (15 mi) when properly raised and is immune to conventional IR smoke and other visual concealment methods.

In normal hunter-killer operation, the commander uses the panoramic sight to scan for and select targets for the gunner to engage, with the control system developing a firing solution from the moment the target is designated. The commander is then free to search for other targets or observe the gunner's engagement. The panoramic sight and sensor mast include laser designators for precision strikes from aircraft, artillery, or guided missiles.

Mobility

Tactical

Engine

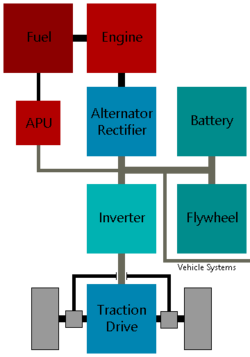

The Jaguar II is powered by a series hybrid drivetrain composed of a 1,200 kW (1,600 hp) Danel Group DVR-2-12/1200E diesel engine connected to a 1,600 kW (2,100 hp) North Iberian RAT-40-16B electric traction drive. This arrangement gives it a maximum road speed of 85 km/h (53 mph) and 64 km/h (40 mph) cross-country, although in peacetime speeds are restricted to 65 km/h (40 mph) to reduce automotive and road surface wear. The engine is multi-fuel capable and is normally operated on SFT-08 jet fuel, which was standardized in 1988 and is similar to commercial aviation fuel with the addition of several stabilizers as well as a specified cetane index.

The DVR-2-12/1200E diesel engine was developed for the HTA-02 based on the original DVR-1-12/1200 oil-cooled engine developed for the HTA-01 Rhinoceros. While similar in design concept, the DVR-2-12/1200E has a smaller displacement of 30.5 liters (1,860 cu in) and better reliability than its predecessor. The DVR-2-12/1200E is a low heat-rejection design using higher temperatures for higher efficiency due to the higher boiling point of the engine coolant. Using experience gained from the DVR-1-12/1200, the DVR-2-12/1200E is designed for greater reliability and servicing intervals, addressing early maintenance issues experienced with the original design. The engine is boosted by a hybrid turbocharger to eliminate turbo lag and transfer extract excess exhaust energy as electricity for the batteries or onboard systems.

The RAT-40-16B electric drive is composed of four permanent magnet motors with a mechanical cross-drive for regenerative steering. While roughly the same weight as the mechanical Elissa-Arishat HM-22A-19, the RAT-40-16B is more compact and has greater power output to the sprockets. The traction drive functions as a continuously variable transmission and provides smooth acceleration with high instantaneous torque. An eddy current retarder provides improved stopping distance and is automatically activated when stopping at speeds above 30 km/h (19 mph).

With no mechanical connections between the engine, electric drive, battery, and APU, all of these elements can be easily disconnected and removed independently for servicing or replacement. The powerpack elements are mounted onto a frame that can be easily slid or lifted out for maintenance and each component removed individually for repair. The engine can be removed and replaced in less than 30 minutes and the battery pack in less than 10 minutes.

With four fuel tanks storing a combined 1,400 liters (370 U.S. gal) and a 150 kWh battery pack, the Jaguar II can travel 775 kilometers (482 mi) on fuel under optimal conditions. External tanks holding 360 liters (95 U.S. gal) can be attached at the rear to supplement range further although these have been largely replaced by sponson-mounted fuel containers with the same capacity to reduce vulnerability. Under optimal conditions, fuel consumption is 0.56 kilometers per liter (1.3 mpg‑US). To power the electronics while stationary, a 30 kW gas turbine auxiliary power unit is also installed in the engine bay, connected to the main power system.

Suspension

The active hydropneumatic suspension allows the vehicle to dynamically adjust ride height for each wheel, allowing the vehicle to lower itself as far as 10 centimeters (3.9 in) for highway driving or increase its ground clearance up to 60 centimeters (24 in) for off-road operations. This also allows the Jaguar II to complement main gun elevation and depression by adjusting ground clearance to the front or rear of the tank and ride height can be automatically adjusted based on information from the forward millimeter wave scanner.

The Jaguar II is supported by seven pairs of 750-millimeter (30 in) HWA-730AD road wheels, composed of a composite fiber-resin inner wheel protected by polymer-clay impregnated polyurethane wear strips. The use of composite road wheels reduces the vehicle's unsprung mass and improves ride quality in off road situations. The 650 mm (25.6 in) tracks are of conventional double-pin double-block construction with titanium reinforcement, covered with removable rubber pads for reduced friction. In order to keep ground pressure within acceptable bounds, the tracks were widened relative to those used in the Rhinoceros. In cold weather or environments where additional traction is desired, steel grousers may be substituted for every fourth track pad. Four return rollers support the track between the front idler and rear sprocket.

Other provisions

With an attached fording kit, the vehicle can cross bodies of water up to 6 meters (20 ft) in depth, and 1.5 meters (4.9 ft) without any preparation at maximum ride height. Tank desant provisions require the turret to be locked forward, at which point infantry can be accommodated along the tank's flanks, although this also disables the APS modules along the sides. Normal procedure is for troops to be disembarked before combat but if ambushed, the standard response is to deploy smoke to cover the dismounting of the infantry before unlocking the turret and proceeding into combat.

An anti-mine system and dozer blade can also be fitted to the front of the vehicle for use against counter-mobility emplacements. The Jaguar II's high torque and reinforced frame allow it to push through a wide array of potential obstacles with minimal if any damage. One vehicle per platoon also normally carries a tow bar to assist stricken comrades.

Strategic

Due to its weight, the Jaguar II can only be carried by large strategic airlifters such as the RTS-224B, which can carry two battle-ready Jaguar IIs or the RTS-224A MRTT which can carry a single battle-ready tank. This makes aerial deployment of a major armored formation expensive and time consuming, a problem that in recent years has spurred the creation of more airmobile light cavalry brigades to provide greater deployment flexibility. The preferred deployment method for overseas engagement is by ship, as an entire division's motor pool requires only a small handful of ships for transport. For amphibious operations the Jaguar II is normally ferried to shore by landing craft or disembarked from a transport directly in port.

Domestically, rail deployments require the armored skirts to be removed and stowed separately to accommodate the national loading gauge. For this reason they can be easily removed and separated into sections for easier stowage. Under normal conditions the vehicle is carried either by rail or by wheeled tank transporter to avoid wear on the tank's automotive components or the road surface. The WLH-62 is the standard transporter, replacing the older LVH-70 and specifically designed to carry the Jaguar II's heavier weight. The vehicle has space for the tank's three crew and can operate on and off road.

Crew provisions

Awareness

Battlefield awareness is provided a peripheral vision system by eight combination vision blocks arranged in two four-block forward groups plus four additional blocks covering the rear arc on the turret roof. Each forward block has a daylight TV camera as well as an optical pass-through while the rear blocks lack the optical channel. Together these blocks provide continuous 360° coverage. The driver is equipped with an array of three similar vision blocks in the forward hull but can use feeds from the roof-mounted blocks through the central management system. Supplementing these sensors are the commander and gunner's sights, both equipped with rangefinders and stabilization for more accurate use on the move. Ka band radar units are mounted on the turret's flanks to allow detection and tracking of incoming munitions.

To meet detection range criteria, a retractable sensor mast is carried by one vehicle per platoon and all vehicles attached to reconnaissance squadrons and is composed of a large ground surveillance radar along with a microphone array for the gunshot locator and another TV/IR sighting system. The mast allows the vehicle to peer over obstacles and extend the visual range to the horizon, allowing for more effective indirect fire using smart munitions or ATGMs. Additional data may be provided via UAV, and the Jaguar II may be equipped with a compact UAV launch system.

Visual data is provided to crew members through high-resolution screens mounted to all stations. This allows the crew a full 360° field of view without the need to leave the tank. Crew members can switch at will between input sources, including the commander and gunner's sights, mast-mounted sensors, and fixed vision blocks. The commander, gunner, and driver each have independent hatches for heads-up viewing although the remote weapon station obscures the gunner's forward vision from his hatch. All crew stations share a number of common controls and interfaces, allowing all crewmen to operate the main and secondary armaments, although only the driver has control over the vehicle's movement. Data may also be transmitted to other vehicles or infantry equipped with the appropriate viewing and data link equipment.

While initial prototypes were equipped with conventional copper wiring for data transmission, production model Jaguar IIs use an optical fiber data bus, improving bandwidth and reducing weight significantly. The ballooning complexity of the combat management system resulted in an initial weight gain of some 1.2 tonnes for new hardware and wiring, while the switch to fiber optics resulted in a total savings of some 3 tonnes, along with the increase in throughput and reduced vulnerability to EMP effects.

Comfort and stowage

The conversion to a three man crew by Carthaginian tanks in the 1970s resulted in greater attention to crew comfort through progressive models of the MBT-74 and leading to the Jaguar II. Crew members are allotted an average of 1.6 m3 (57 ft3) of internal space and the crew members are issued microclimate air-cooled vests to maintain comfortable temperatures with a supplementary cooling system for onboard electronics. Seats are adjustable in height and inclination, while potable water taps are available in the hull along with a heating plate for cooking use.

The vehicle is protected by a CBRN overpressure system with filters for incoming air. Limited space in the hull is available for personal effects and a stowage rack for small arms is included, normally equipped with three G/IAR-102C carbines for use when dismounted. UAV storage is also located externally on the rear of the turret and the commander is responsible for preparing the UAV for launch.

Additional crew and equipment stowage is available in the external bustle racks. Limited stowage is available in the rear and hull flanks and it is not unknown for crews to store additional equipment on top of the external fuel tanks if mounted.

Variants

Variants based directly on the HTA-02 Jaguar II:

- XTA-02: Prototype model first completed in 2005. An additional sixteen prototypes were manufactured over the next five years for extended trials and experimentation. All are retired and several are on display in museums.

- HTA-02: Full-rate production model first produced in late 2010. 10,300 produced to date from four factories. Production continues at 800 units per month for all operators.

- HTA-02LRP: Initial low-rate production model first produced in early 2010. Built without the FRC-354 remote weapon station and sensor mast, and featuring a traditional ring mount for the commander's grenade launcher. 140 produced, all later refitted to production standard.

- HTA-02UR: Prototype urban combat equipment package incorporating additional reactive armor on the skirts and additional armor for the roof, turret sides, and turret rear.

- HTA-02DTT: Driver training tank to acclimate drivers to the hybrid drivetrain and new control system. Equipped with a panoramic vision system in the turret and a false gun, along with space for two additional students to observe.

- HTA-02AM1: First major design revision. Upgrades include a new range gated night vision system, improved processing systems, higher-bandwidth radios, improved counter-IED and turret armor, a new battery pack for the powerplant, and an RWS-integrated drone jammer and radar. Final testing began in March 2016 and the first units were delivered in November 2017.

- HTA-02NG: Proposed alternative variant incorporating crew-in-hull seating and a new unmanned turret design.

- HET-11 Thoas: Armored recovery vehicle incorporating a powered winch, crane, light earthmoving spade, additional fuel tanks, and armed with a single CRA-334 chain gun. The vehicle also has space to recover the crew of a damaged tank in the event it must be returned to a depot.

- HEC-12 Ajax: Combat mobility vehicle equipped with constant-depth mine plough, bucket arm, mine clearing line charge launcher, lane-marking equipment, and CRA-334 chain gun in remote mount.

- HEB-13 Moses: Armored vehicle-launched bridge, carrying a 28-meter (92 ft) bridge rated for up to 80 tonnes. Replaces the older MEB-74R based on the MBT-74 chassis.

- HCA-20 Shango: Short range air defense vehicle armed with 50 mm rotary cannon and surface to air missiles.

A related vehicle platform, the Heavy Brigade Armored Fighting Vehicle (HB-AFV), is based on the Jaguar II chassis and automotive components but is redesigned with a forward-mounted engine to accommodate a larger rear payload and direct rear access. A number of fighting vehicles are based on this platform and intended for use alongside the Jaguar II in armored brigades:

- HIV-06 Eryx: Heavy IFV with seating for a full squad of 9 troops plus vehicle crew. Armed with a 40 mm autocannon and box-mounted ATGM launcher.

- HRA-07 Perses: Reconnaissance vehicle armed with 40 mm autocannon and ATGM launcher, and carrying additional sensors and unmanned ground vehicles. Also carries three foot mobile scouts.

- HMA-08: Mortar carrier armed with twin-barrel 120 mm automatic mortar system. Program cancelled in 2013.

- HHM-09 Bowman: 155 mm L/56 self-propelled gun-howitzer.

- HHA-10 Fletcher: Munitions carrier for HHM-09, equipped to carry 120 155 mm shells and their charges with an automatic reloading system.

- HOM-14 Apollo: Multiple launch rocket system carrying twelve 220 mm rockets and also capable of firing the TDR-592 Shapash tactical ballistic missile.

- HAB-15 Pegasus: Battlefield ambulance with space for up to six patients and a dedicated attendant's station to monitor passengers. Normally unarmed and marked with medical insignia, although these can be removed and a remote weapon station installed in particularly hostile environments.

- HVB-16 Delphi: Command vehicle equipped with additional communication systems and armed with a 15.5 mm CRA-334 chain gun.

- HHM-18 Oshosi: 210 mm L/52 self-propelled gun.

- HHA-19 Ogun: Munitions carrier for the HHM-18, carrying up to 72 210 mm shells and their charges with an automatic reloading system.

Operators

Carthage – 14,600 vehicles in service combined with 54,200 on order to replace existing inventory of HTA-01 Rhinoceros tanks. It is expected that follow-on orders of improved models will allow earlier models to be transferred to the National Militia.

Carthage – 14,600 vehicles in service combined with 54,200 on order to replace existing inventory of HTA-01 Rhinoceros tanks. It is expected that follow-on orders of improved models will allow earlier models to be transferred to the National Militia.

- Army of Carthage: 14,280 vehicles in service with another 38,720 on order.

- Naval Infantry: 320 vehicles in service with another 880 on order.

Gensokyo Republic – Gensokyo Republic Ground Forces: 1,200 vehicles in service, with 1,000 on order. Most components produced abroad in Japanese and Carthaginian factories, but integration is handled domestically under license. The Gensokyo Republic is the first export customer of the HTA-02.

Gensokyo Republic – Gensokyo Republic Ground Forces: 1,200 vehicles in service, with 1,000 on order. Most components produced abroad in Japanese and Carthaginian factories, but integration is handled domestically under license. The Gensokyo Republic is the first export customer of the HTA-02. Japan – 1,950 vehicles in service combined as the Type 71 Se-Tsu, with another 9,500 on order to replace existing inventory. Japanese tanks are produced on domestic lines.

Japan – 1,950 vehicles in service combined as the Type 71 Se-Tsu, with another 9,500 on order to replace existing inventory. Japanese tanks are produced on domestic lines.

- Imperial Army: 1,600 vehicles in service with another 8,850 on order.

- Special Naval Landing Forces: 350 vehicles in service with another 650 on order.

See also

Related development

Related lists

Tanks of comparable role, type, and era

Details

| HTA-02 Jaguar II | |||

| Average unit cost | NSD$16 million (FY2014) | Manufacturer | Danel Group Armored Solutions Tingis-Lixus Mobility Systems |

| Proliferation | Carthage Gensokyo Republic Japan |

Production | 2011-present |

| Production to date | 17,750

950 exported |

Crew | 3 (commander, driver, gunner) |

| General Characteristics | |||

| Combat weight | 64.2 tonnes (71 short tons) | Height over hull | 2.56 m (8.4 ft) |

| Hull length | 8.03 m (26.3 ft) | Length with gun forward | 11.55 m (37.9 ft) |

| Width over skirts | 3.85 m (12.6 ft) | Ground clearance | Variable 0.1-0.6 m (3.9-23.6 in) |

| Fire height | 1.9 m (6.2 ft) | Ground pressure | Nominal: 89.35 kN/m2 (0.911 kg/cm2) Mean Maximum: 237 kN/m2 (2.41 kg/cm2) |

| Armament | |||||

| Type | Feed | Ammunition | Traverse | Elevation | Maximum effective range |

| 155 mm L/46 CBS-321 smoothbore gun | CEB-322 two-part bustle + hull autoloader | 36 rounds | 360° (45°/sec) | +24° to -8° | 10,000 m w/guided munitions |

| CRA-336 7 mm PCTA electrically-operated chain gun, coaxial | 3,000-round feed system | 8,400 rounds | 360° | +24° to -8° | 1,000 m |

| CRA-334 15.5 mm PCTA electrically-operated revolver cannon in FRC-354 remote weapon station | 100-round ammunition box | 1,300 rounds | 360° | +50° to -20° | 2,500 m |

| IAG-127 30 mm gas-operated automatic grenade launcher in FRC-354 remote weapon station | 40-round ammunition box | 200 rounds | 360° | +50° to -20° | 2,000 m |

| Fire Control | |||

| Gunner's sighting system | Commander's surveillance system | ||

| Stabilized BSI CMOS + ICCD day sight and dual-band FLIR (LWIR/MWIR) night sight, CO2 laser rangefinder | Stabilized panoramic BSI CMOS + ICCD day sight and LWIR FLIR night sight, CO2 laser rangefinder, Peripheral vision system | ||

| Driver's primary viewing system | Battlefield management system | ||

| 3 optical vision blocks, optional ICCD and FLIR night sights | ECR-571 multiband/multimode VHF/UHF radio, GPS/INS and electronic compass, EPU-592 centralized combat management system | ||

| Drone provisions | Battlefield awareness | ||

| Modular UAV Control Interface-compatible | Deployable sensor mast w/FLIR, ground surveillance radar, gunshot locator system | ||

| Armor & Protection | |||||

| Assembly | Structural armor | Spall liner | |||

| Laser hybrid welding | Dual-hardness steel, fiberglass mounting | Polyethylene spall liner w/boron filler | |||

| Passive armor array | Steel/aluminum/rubber spaced armor, steel/silicon nitrate/silicone NxRA, silicon carbide tiles, UO2-100 strike plate, and aluminum foam | ||||

| Floor protection | Titanium diboride, steel spaced armor, aluminum foam, internal sloped-hull | ||||

| Add-on armor | Ōarai-type explosive reactive armor, optional cage armor | ||||

| CBRN protection | Sealed hull w/overpressure system, depth and centrifuge filtered, boron radiation shield | ||||

| Fire suppression | Active protection system | Concealment | |||

| Automatic HFC-227a fire extinguisher system | Radar/IR multi-tier Rho Aias APS w/two-tier hardkill defense and two-tier softkill defense | 2 x 10 tube (2 grenades per launcher) smoke dispensers | |||

| Estimated turret protection | Estimated hull protection | Estimated ERA protection | |||

| Mantlet: 140 mm APFSDS, 180 mm HEAT Weakened zone: 140 mm APFSDS, 180 mm HEAT Front side turret: 105 mm APFSDS, 150 mm HEAT Side turret: 80 mm APFSDS, 105 mm HEAT Rear turret: 40 mm APFSDS, 75 mm HEAT Roof: 35 mm APFSDS, 70 mm HEAT |

Front hull: 120 mm APFSDS, 150 mm HEAT Front 1/3 side hull: 80 mm APFSDS, 150 mm HEAT Side hull: 80 mm APFSDS, 105 mm HEAT Rear hull: 40 mm APFSDS, 75 mm HEAT Engine deck: 35 mm APFSDS, 70 mm HEAT Floor: 40 mm APFSDS, 105 mm HEAT |

Front turret: 155 mm APFSDS, 200 mm HEAT Side turret: 105 mm APFSDS, 150 mm HEAT Front hull: 140 mm APFSDS, 180 mm HEAT Side hull: 105 mm APFSDS, 150 mm HEAT Rear hull: 105 mm APFSDS, 120 mm HEAT Roof/engine deck: 80 mm APFSDS, 105 mm HEAT | |||

| Automotive | ||

| Powerplant | Output | Fuel Capacity |

| Danel Group DVR-2-12/1200E V-12 turbocharged multi-fuel diesel engine | 1,200 kW (1,600 hp) 24.9 kW/tonne (33.4 hp/tonne) |

1,400 l (370 US gal) internal, 150 kWh battery pack |

| Transmission | Steering | Brake system |

| North Iberian RAT-40-16B series electric traction drive | Electric with mechanical regeneration, T-bar control | Electromagnetic regenerative brakes w/eddy current retarder |

| Suspension | ||

| Type | Road wheels | Return rollers/idlers |

| Two-cylinder single-piston in-arm active hydropneumatic | 14 750 mm (30 in) independently-sprung dual track wheels HWA-730AD rubber-tired polyurethane-lined composite |

Four return rollers per side |

| Drive sprockets | Idlers | Shock absorbers |

| 12-tooth rear drive | Dual compensating front idlers | All |

| Tracks | |||||

| Type | Center guide, dual-pin, double-block rubber-padded | ||||

| Width | Shoes per track | Track pitch | Ground contact length | ||

| 650 mm (26 in) | 93 | 180 mm (7.1 in) | 5.42 m (17.8 ft) | ||

| Performance | |||||

| Maximum level road speed | 85 km/h (53 mph) | Gradient | 60% | Maximum vertical obstacle | 1.25 m (4.1 ft) |

| Maximum off road speed | 64 km/h (40 mph) | Side slope | 30% | Maximum fording depth | 1.5 m (4.9 ft) unprepared 6.0 m (19.7 ft) with snorkel |

| Average cross country speed | 40-60 km/h (25-37 mph) | Minimum turning diameter | Pivot | Maximum trench-crossing distance | 295 cm (116 in) |

| Operational range | 775 km (482 mi) fuel + 225 km (140 mi) w/external tanks, 15 km (9.3 mi) battery, 1,000 km (620 mi) maximum combined | ||||